Support structure for a wind turbine and procedure to erect the support structure

a technology for supporting structures and wind turbines, which is applied in the direction of mechanical equipment, building repairs, machines/engines, etc., can solve the problems of high cost of assembly of towers, inability to deal with, in a cost-effective manner, against the cost-effectiveness of the project, etc., and achieve the effect of reducing the cost of assembly and reducing the cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094]In view of the discussed figures and in accordance with the number used, an embodiment of the invention comprising the parts described below can be seen in said figures.

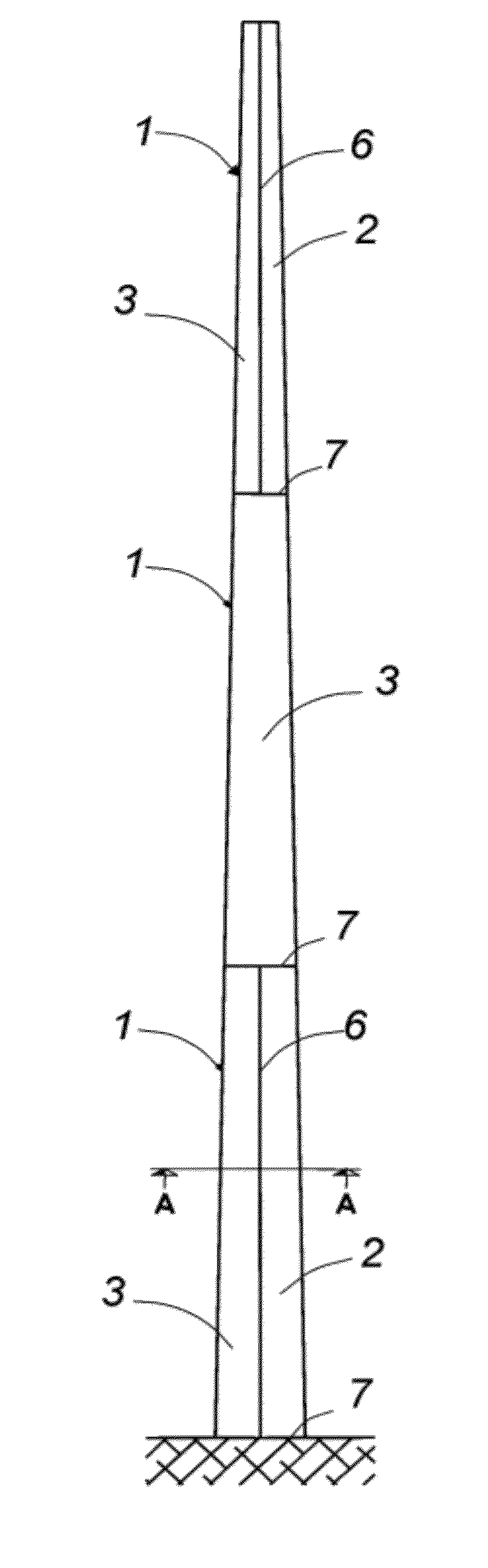

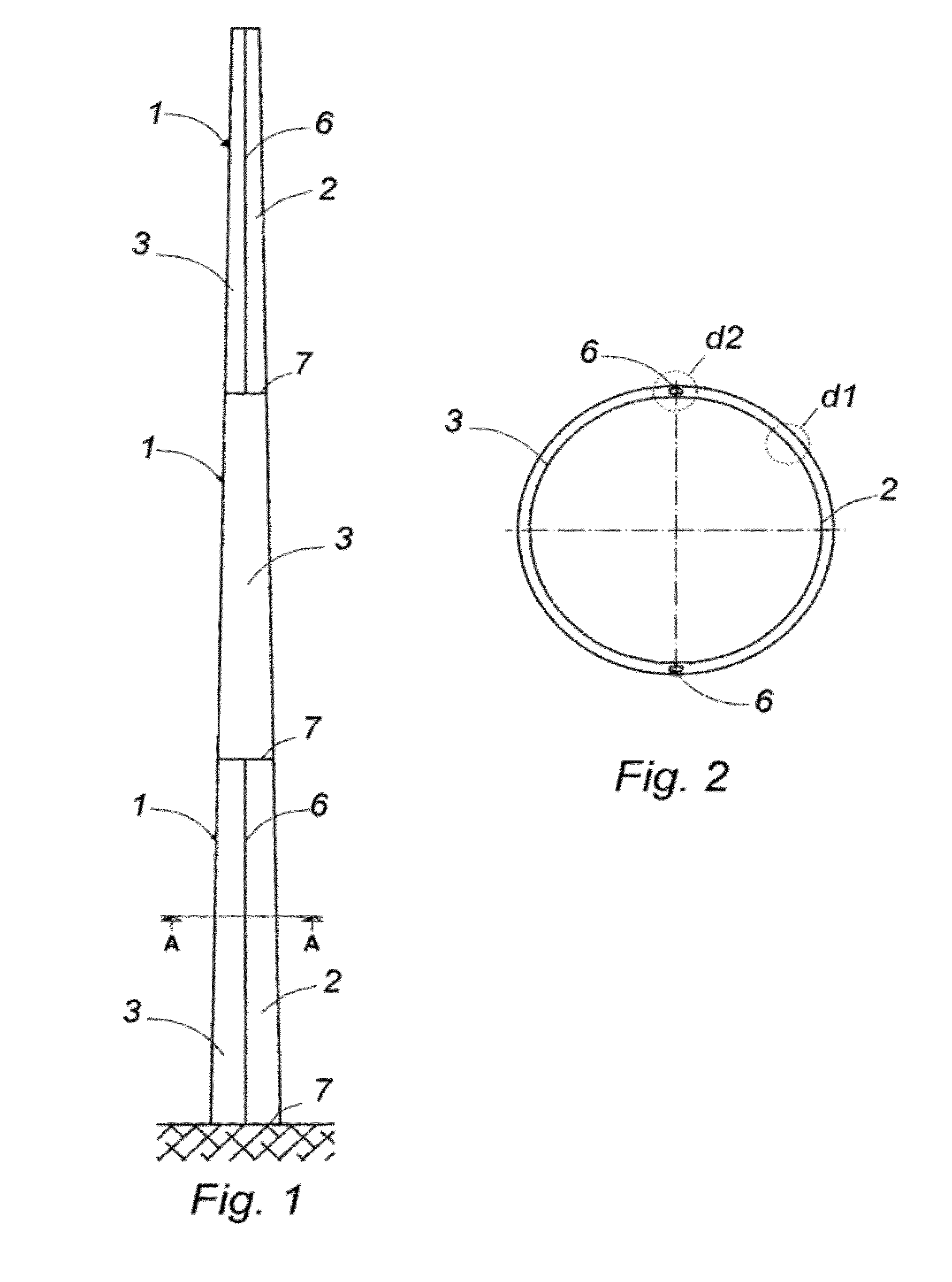

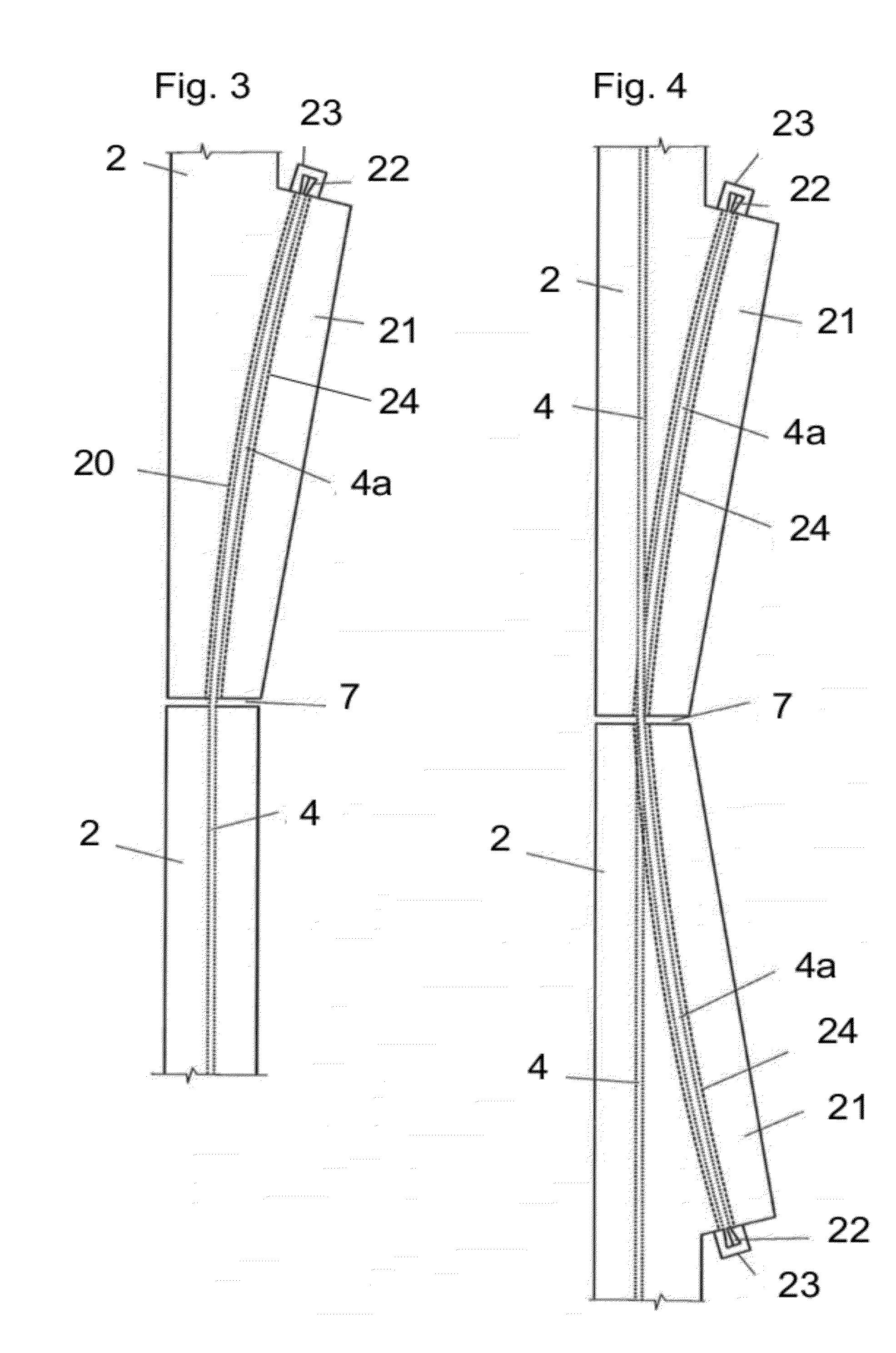

[0095]Thus, as depicted in FIGS. 1 and 2, the support structure for wind turbines generating electric energy and for other uses made of entirely prefabricated prestressed concrete is formed by a prefabricated column shaft -1- made of high-strength concrete which is prestressed or post-tensioned in the manufacturing bed which can self-compacting, if necessary, having a frustoconical shape with variable height made by means of at least two pieces -2- and -3- with semicircular or polygonal section (not illustrated), a thin wall of 5 to 30 cm having a centered prestressing -4- and a non-prestressed reinforcement in the perimeter of the section -5- as is observed in detail “d1” depicted in FIG. 6 and attached to each other by means of longitudinal joints -6-.

[0096]The prestressing -4- can have slight variations with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com