Method and Apparatus for Maintaining Pressure In Well Cementing During Curing

a well and cementing technology, applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of lack of zonal isolation, lack of life and property, and the casing shoes may not test at expected pressure integrity, etc., to increase the radial stress of cured cement and increase the hydrostatic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

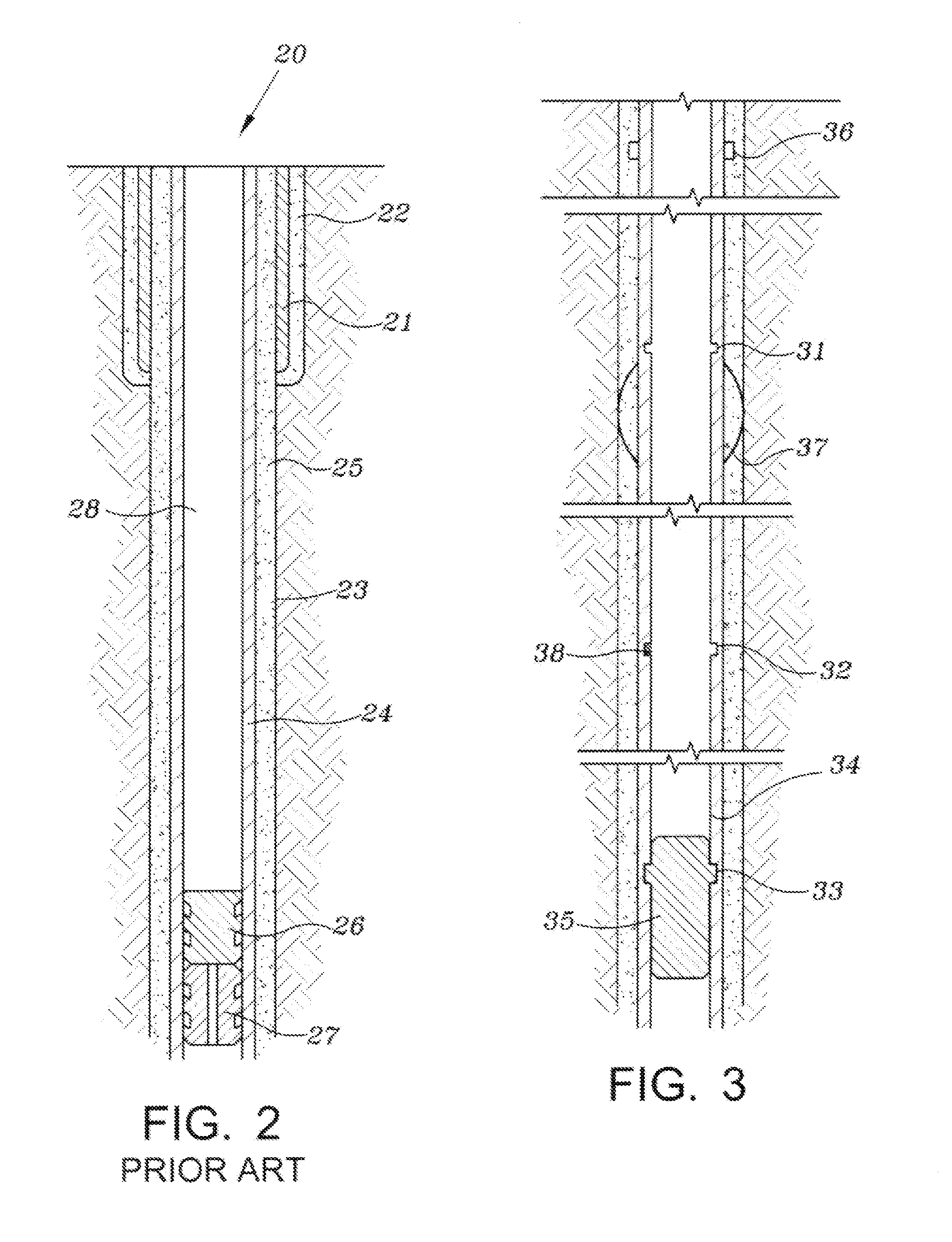

[0027]Referring to FIG. 2 (prior art), well 20 has been drilled by first drilling a hole and cementing casing 21 (conductor casing) with cement 22. A second smaller diameter hole 23 has been drilled out of the bottom of the conductor casing and casing string 24 (“surface casing”) has been cemented in place using cement 25. The cementing operation is well known in the industry. It may involve launching a bottom plug 27 ahead of the cement, pumping the cement, breaking a diaphragm in the bottom plug and launching top plug 26 behind the cement and displacing it with displacement fluid 28 (normally brine or drilling fluid). Sufficient cement may be placed in the well to bring the top of cement back to the surface of the earth (as shown) or the top of the cement may be brought to some selected depth below the surface of the earth. The surface casing extends to a depth below the surface of the earth sufficient to protect all usable water zones. It is very important that the surface casing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore pressure | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com