Chilled Beam Air Conditioning System

a technology of chilling beams and air conditioners, which is applied in the direction of domestic applications, heating types, lighting and heating apparatus, etc., can solve the problems of reducing the optimal air flow of the room through the radiator, requiring significant energy to circulate the cooled air through the structure, and affecting the cooling effect of the room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description is of the best mode presently contemplated for carrying out the invention. This description is not to be taken in a limiting sense, but is made merely for the purpose of describing one or more preferred embodiments of the invention. The scope of the invention should be determined with reference to the claims.

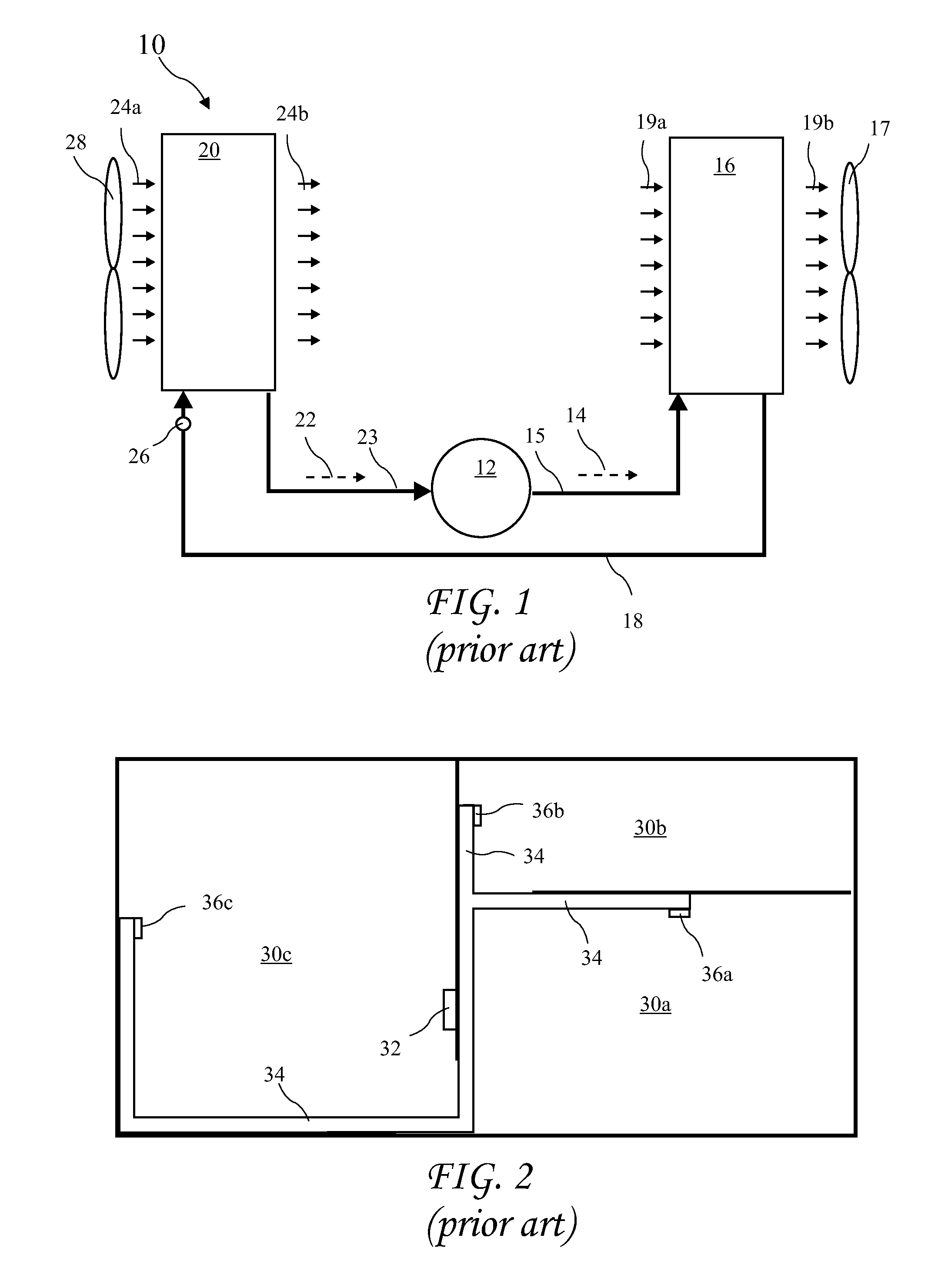

[0032]A diagram showing a known refrigeration and / or air conditioning system 10 is shown in FIG. 1. Typically, the compressor 12 compresses refrigerant into a high-pressure vapor refrigerant flow 14 through a pressure line 15 into a condenser 16. An outdoor fan 17 creates an air flow 19a across the condenser 16 which cools the high-pressure vapor refrigerant flow 14 by removing heat and condenses the high-pressure vapor flow 14 to a liquid state fluid refrigerant flow 18. The heat added to the air flow 19a produces a heated air flow 19b. The liquid state fluid refrigerant flow 18 flows along a refrigerant pipeline, through a metering device 26, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com