Non-tobacco moist snuff composition and a method for its manufacture

a non-tobacco, moist snuff technology, applied in the field of non-tobacco moist snuff composition and a manufacturing method, can solve the problems of lack of similarity, lack of moistness of products, lack of taste and characteristics,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

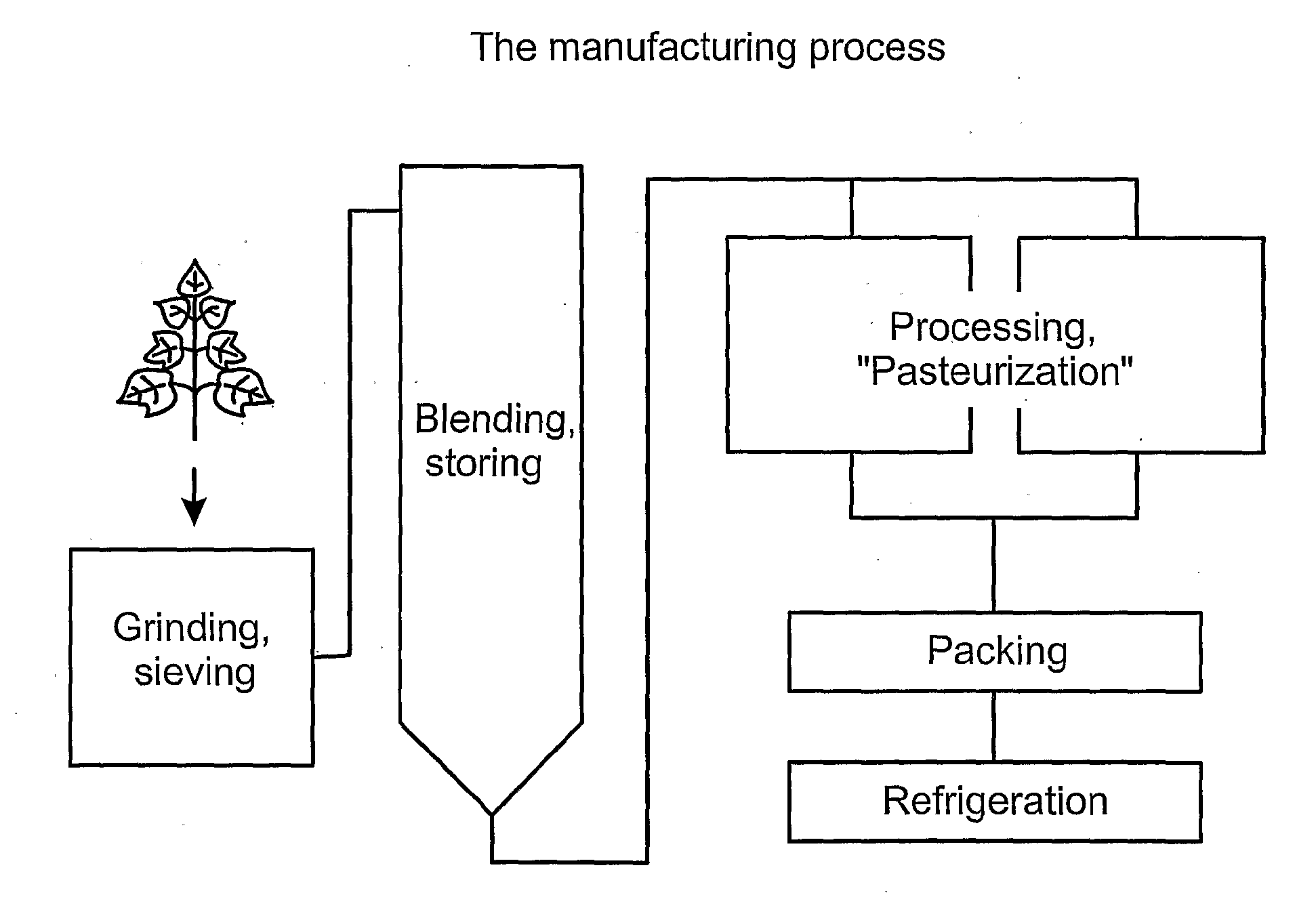

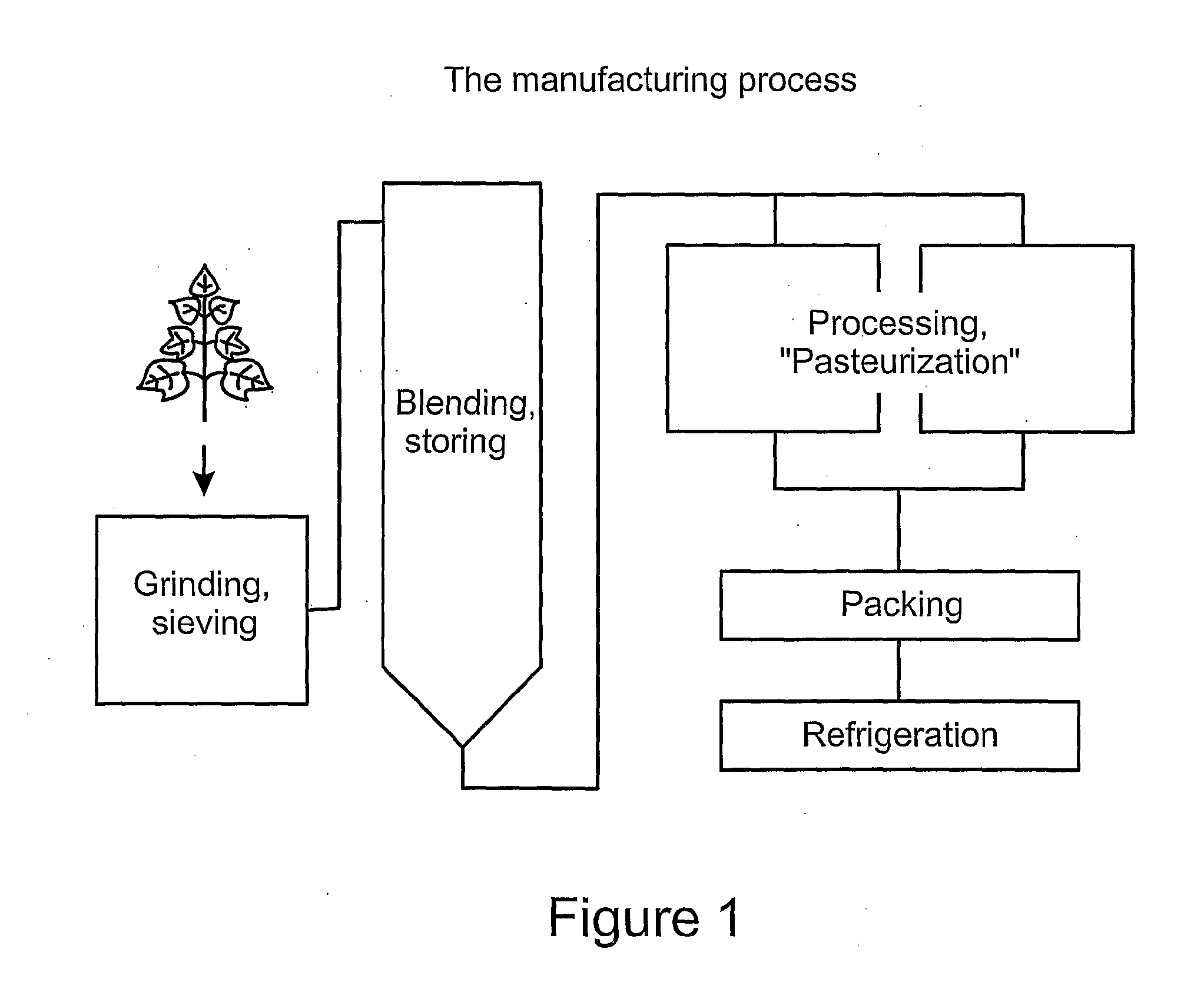

Method used

Image

Examples

example 1

Manufacturing of an Oral Non-Tobacco Moist Snuff Composition Comprising a Mixture of oat and Cocoa Fibers at 65 / 35 w % Proportion

[0060]Oat fibers (VITACEL® Oat Fiber HF 401, supplier LCH Kemiflor AB) and cocoa fibers (Ficao Cocoa Fibre, supplier Femtorp AB), were loaded in a dry and empty 4,200 L horizontal heat treatment mixer with plough shaped shovels on a centered shaft. Of the plant fiber materials loaded, 65 w % were oat fibers and 35 w % were cocoa fibers. The fibers were mixed to a homogenous blend. A solution of water, sodium chloride (NaCl) and glycerol was added to the fiber blend while stirring. Sodium chloride (NaCl) was added to an amount of 3.6 w / w % based on the dry weight of the final composition and glycerol was added to an amount of 5.4 w / w % of the dry weight of the final composition. The mixture was heat treated at a temperature of 70-100° C. for 10 hours accompanied by stirring of the mixture for five minutes every hour. Temperature was retained by intermittent...

example 2

Manufacturing of an Oral Non-Tobacco Moist Snuff Composition Comprising a Mixture of oat and Cocoa Fibers at 80 / 20 w % Proportion

[0062]Following the procedure of Example 1 above, a plant fiber mixture of 80 w % of oat fibers (VITACEL® Oat Fiber HF 401, supplier LCH Kemiflor AB) and 20 w % of cocoa fibers (Ficao Cocoa Fibre, supplier Femtorp AB), was added to a 130 I heat treatment mixer with the same features as the mixer used in Example 1. A solution of water, sodium chloride (NaCl) and glycerol was added to the fiber blend while stirring. The composition was processed, chilled, prepared and packed according to the procedure described above in Example 1. Besides flavorings, water, additional sodium chloride (NaCl) and sodium carbonate (Na2CO3), ingredients with pH buffering properties were added after chilling. Packing of the composition into 1 g portion packages resulted in a non-tobacco snuff product with sensory properties, such as taste, texture and appearance, perfectly resemb...

example 3

Oral Non-Tobacco Moist Snuff Composition Comprising Cocoa Fibers and Corn Fibers

[0064]Two types of plant fibers, Corn Fibers (SOFABRAN™ F 184-400, supplier supplier AB R. Lundbergs) and Cocoa fibers (Ficao Cocoa Fiber, supplier Femtorp AB), were used in the manufacturing of a non-tobacco snuff composition. Of the total amount of fibers added, 83 w % were corn fibers and 17 w % were cocoa fibers. The fibers were loaded to an empty horizontal heat treatment mixer (4200 L) and ingredients (sodium chloride (NaCl), glycerol, powdered liquorice and water) were added. The mixture was blended, heat treated, chilled and prepared with additional ingredients (ammonium chloride, flavorings, sodium carbonate and water). The overall manufacturing process followed the procedures as described in Example 1. The content of the ingredients in the final composition is given in Table 3. Analysis of the final composition proved a dietary fiber content of 50 w / w %, calculated on total weight of the dry we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com