Two piece roof vent

a roof vent and two-piece technology, applied in ventilation systems, heating types, lighting and heating apparatus, etc., can solve the problems of inability to easily form injection molding and relatively bulky roof vents, and achieve the effect of convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

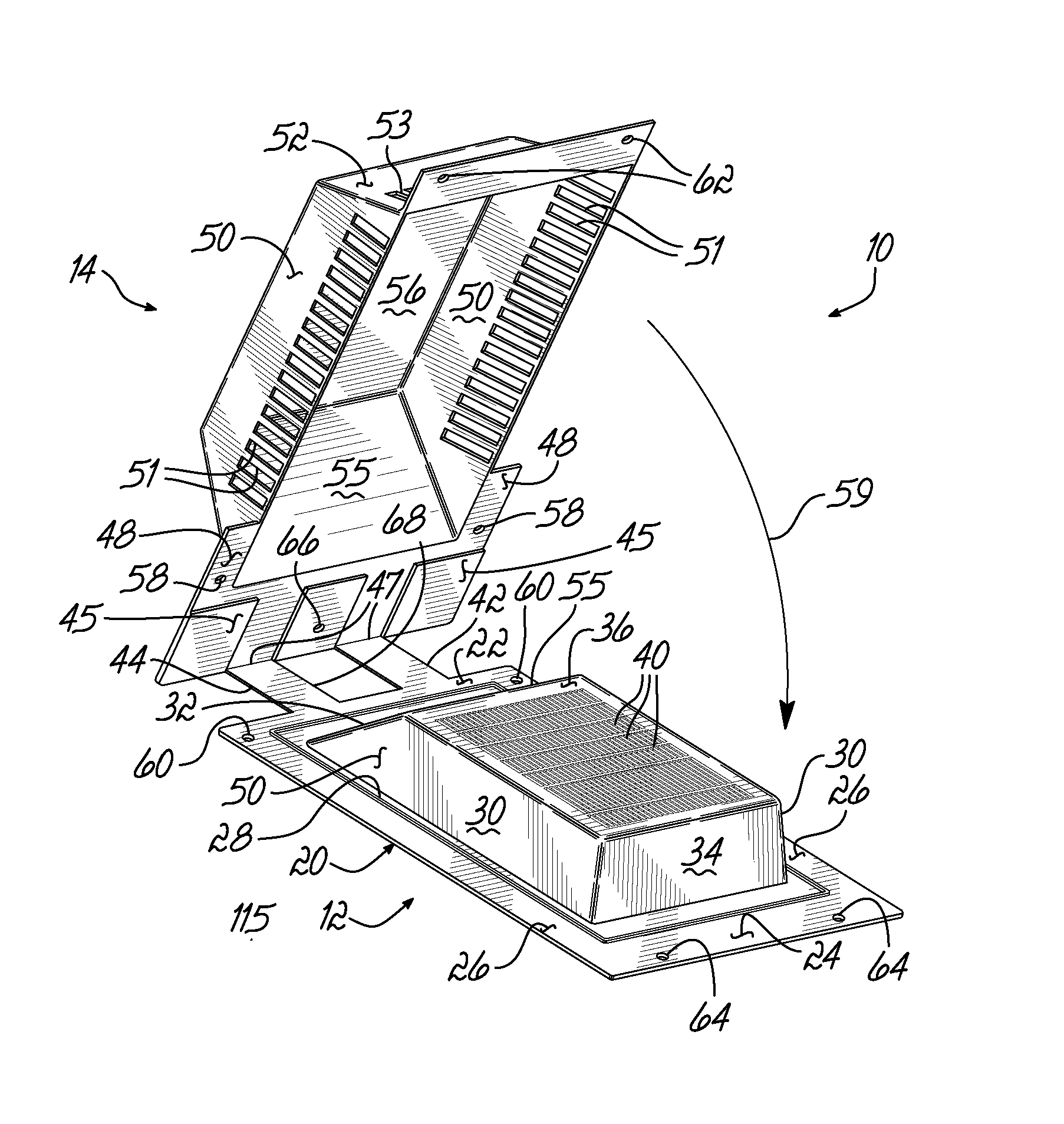

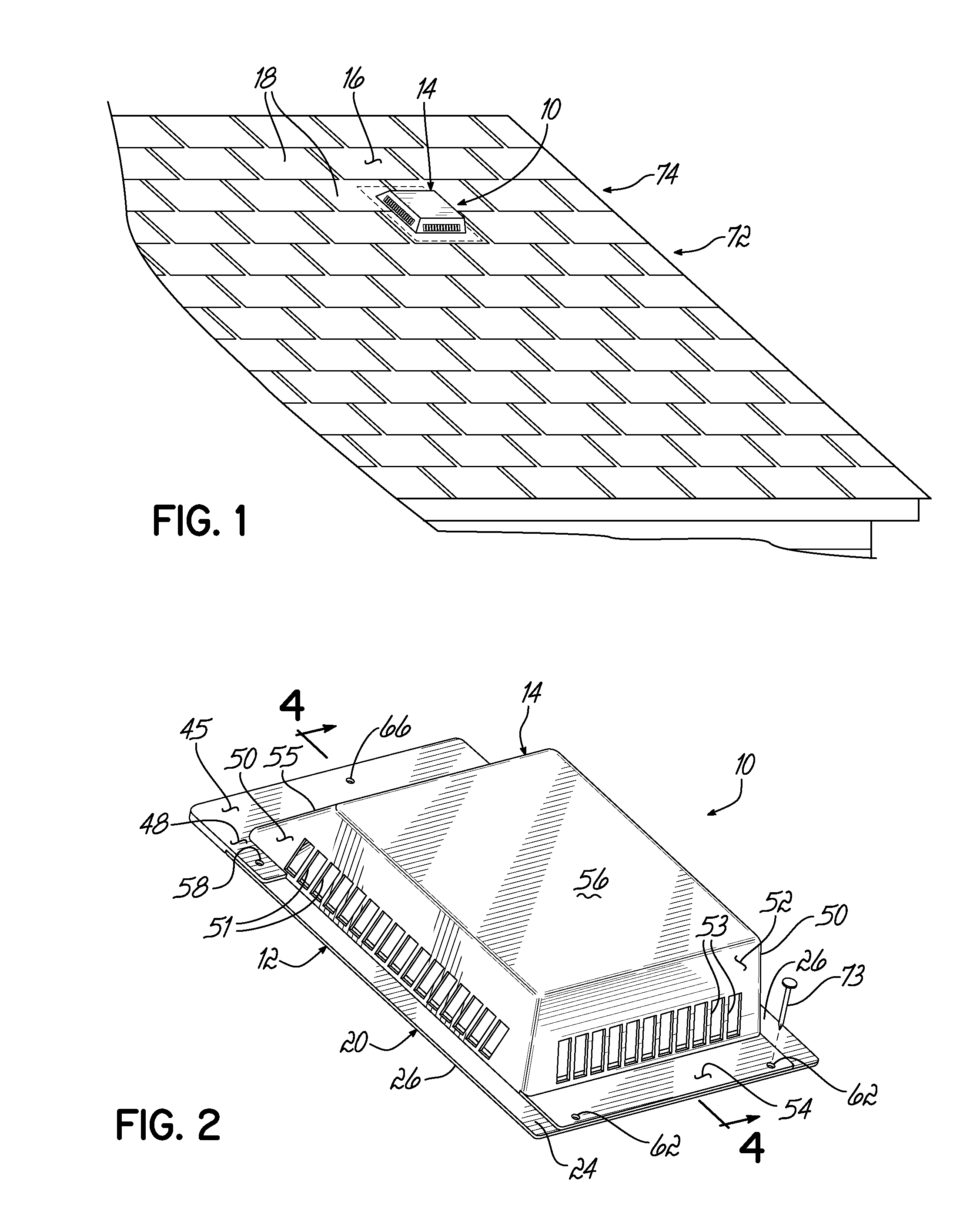

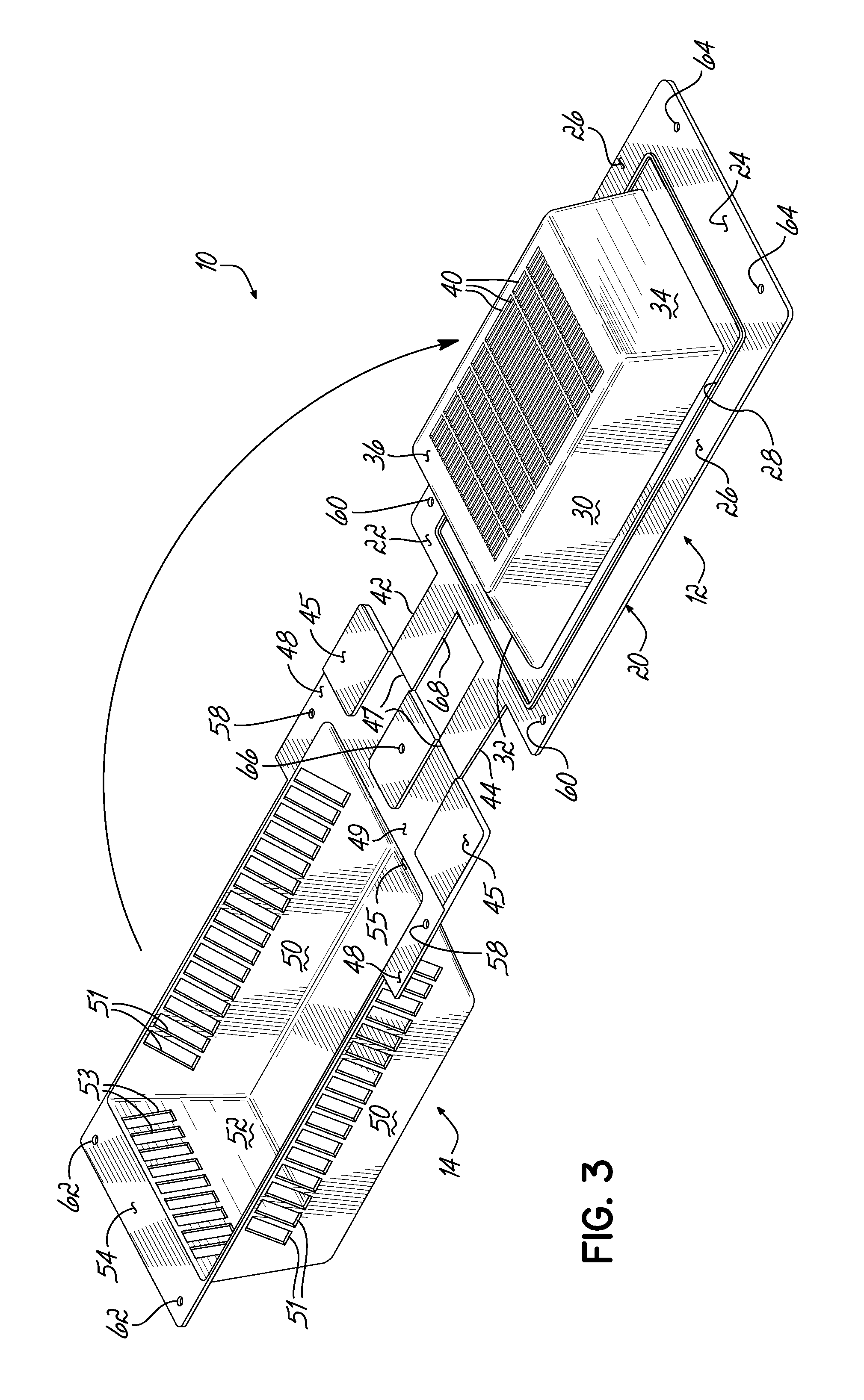

[0013]According to the present invention, a roof vent 10 includes an inner base member 12 and an outer cover member 14. The vent 10 is attached to a roof surface 16 and covers an opening 17 through the roof surface 16. The roof vent 10, in turn, is surrounded by shingles 18. The vent can be plastic and formed by injection molding or the vent can be metal.

[0014]The base member 12 has a peripheral flange 20 formed from a top flange 22, a bottom flange 24 and two side flanges 26. Peripheral flange 20 includes a circumferential raised shoulder 28. Sloped side walls 30, forward wall 32, and back wall, or lower wall 34 extend up from shoulder portion 28 and surround a top wall 36. The base member 12 includes upper air openings 38 through wall 32, and air openings 40 through top wall 36. These openings are relatively small to keep bugs from passing through the vent. The remaining side walls 30 and lower wall 34 are solid to prevent water ingress.

[0015]As shown in the one piece embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com