Gas turbine engine compressor components comprising thermal barriers, thermal barrier systems, and methods of using the same

a technology of thermal barriers and compressor components, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of increasing temperature and difficulty in getting the material to perform properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

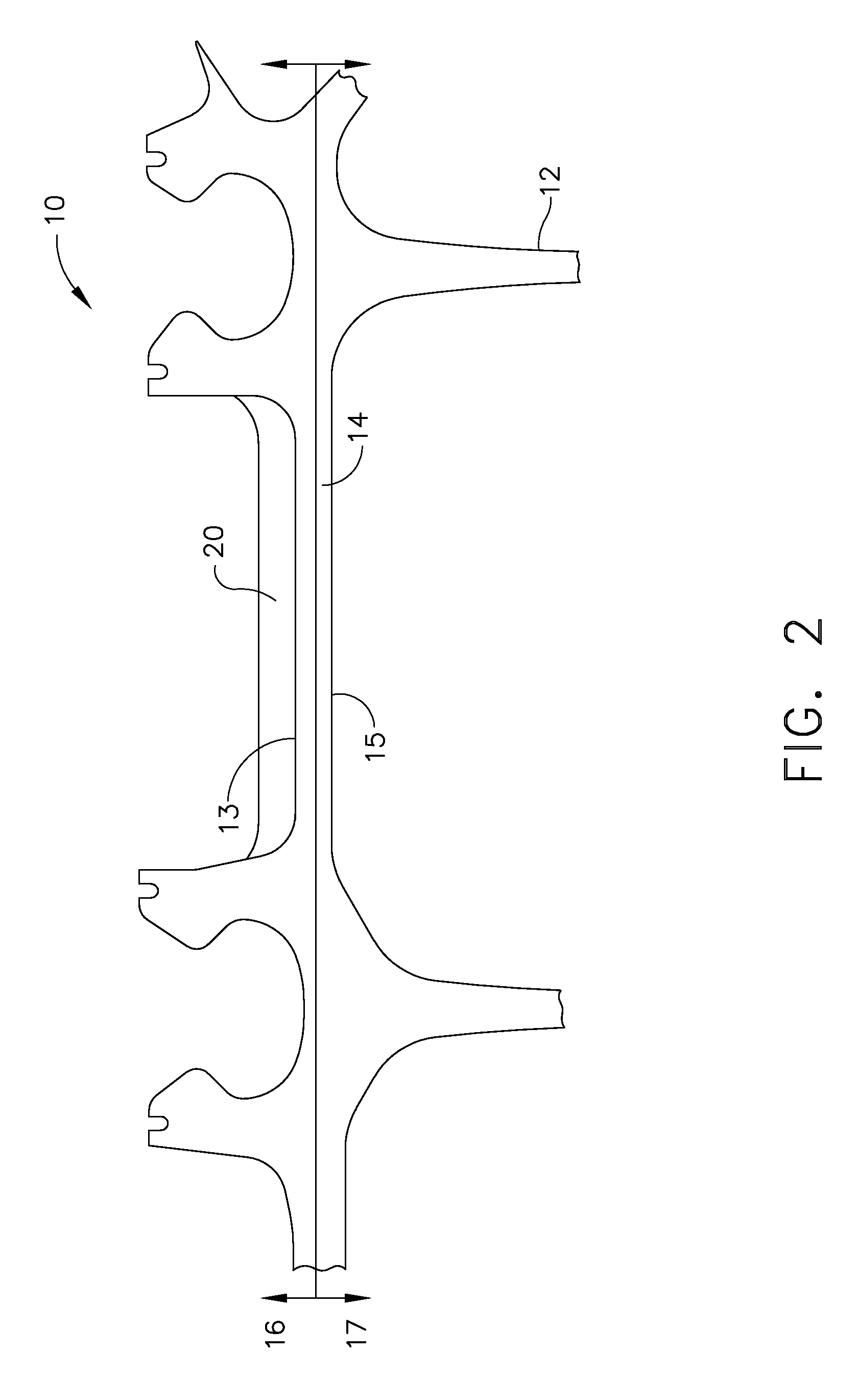

[0014]Embodiments described herein generally relate to gas turbine engine compressor components comprising thermal barriers; thermal barrier systems; and methods of using the same. More particularly, embodiments described herein generally relate to gas turbine engine high pressure compressor shafts and thermal barrier systems for use therewith.

[0015]For purposes of the description herein, the turbine engine compressor component may generally be of any type, however, in one embodiment, the component may be a rotating compressor component, or portion thereof, that experiences a service operating temperature of from about 537° C. (about 1000° F.) to about 788° C. (about 1450° F.), and in one embodiment from about 700° C. (about 1300° F.) to about 788° C. (about 1450° F.). One example of a rotating compressor component that may benefit from the methods and systems described herein can include, but should not be limited to, compressor disks. While the entire disk may be protected, it may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com