Suspension arrangement for clothes washing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

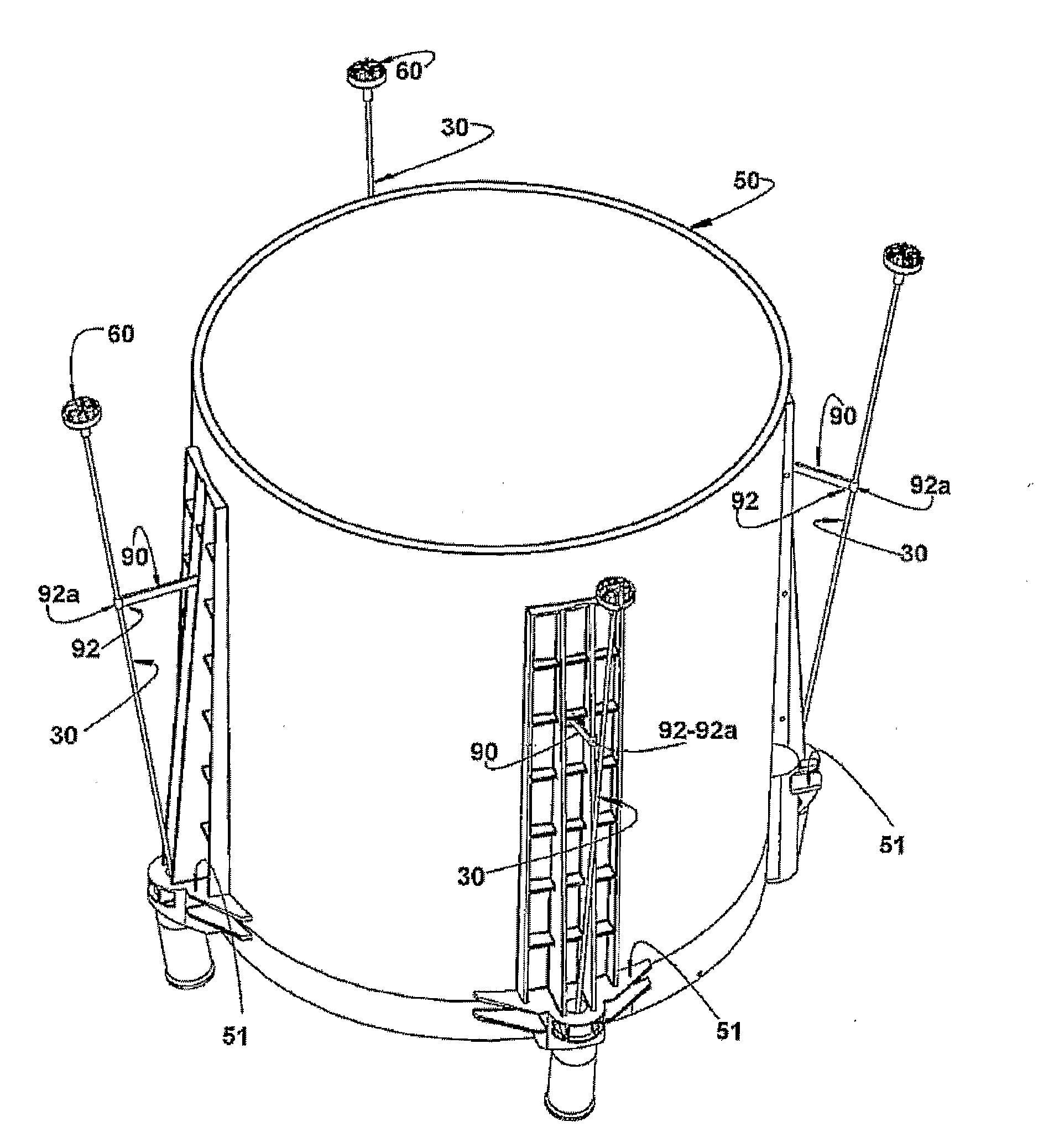

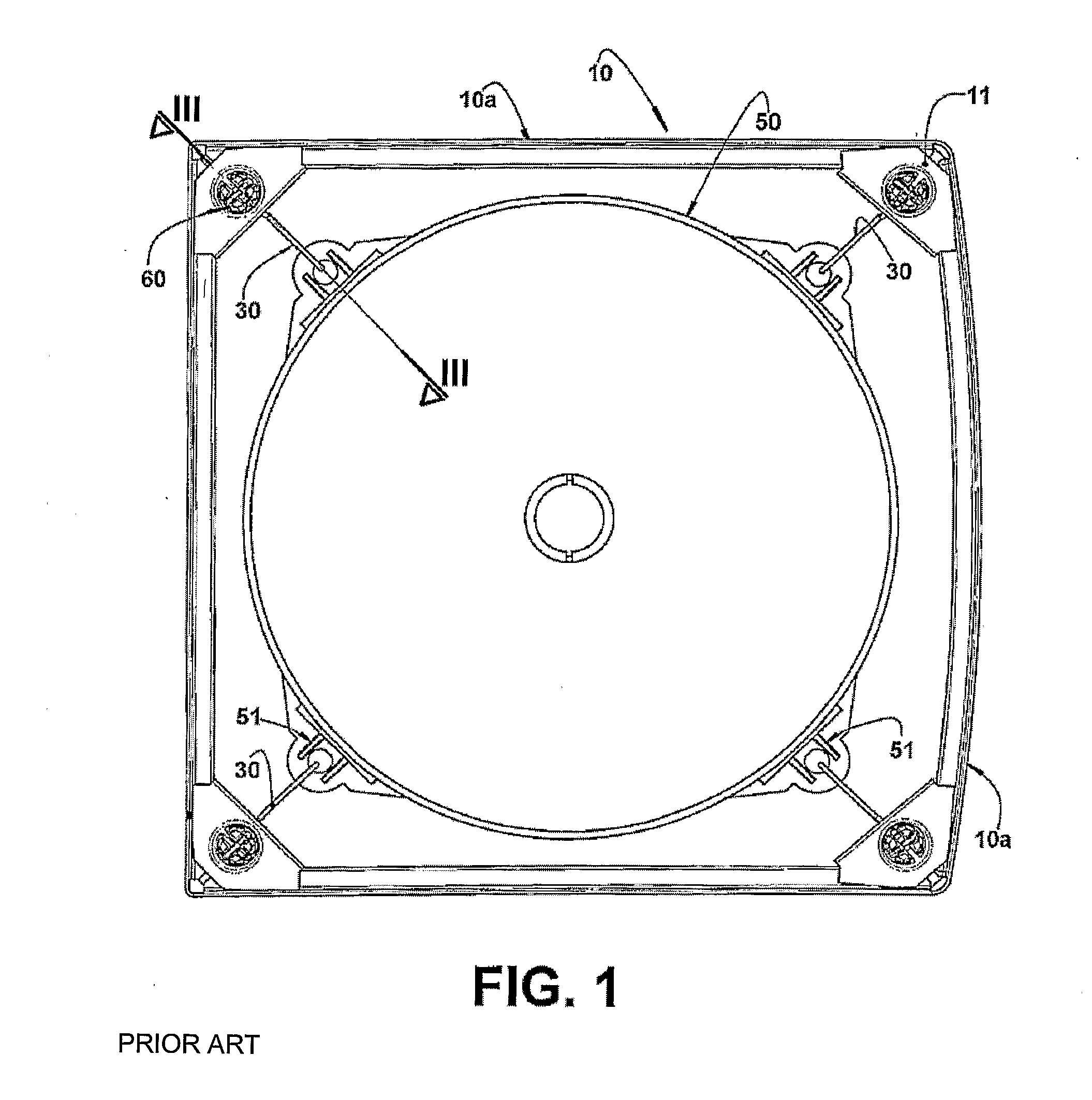

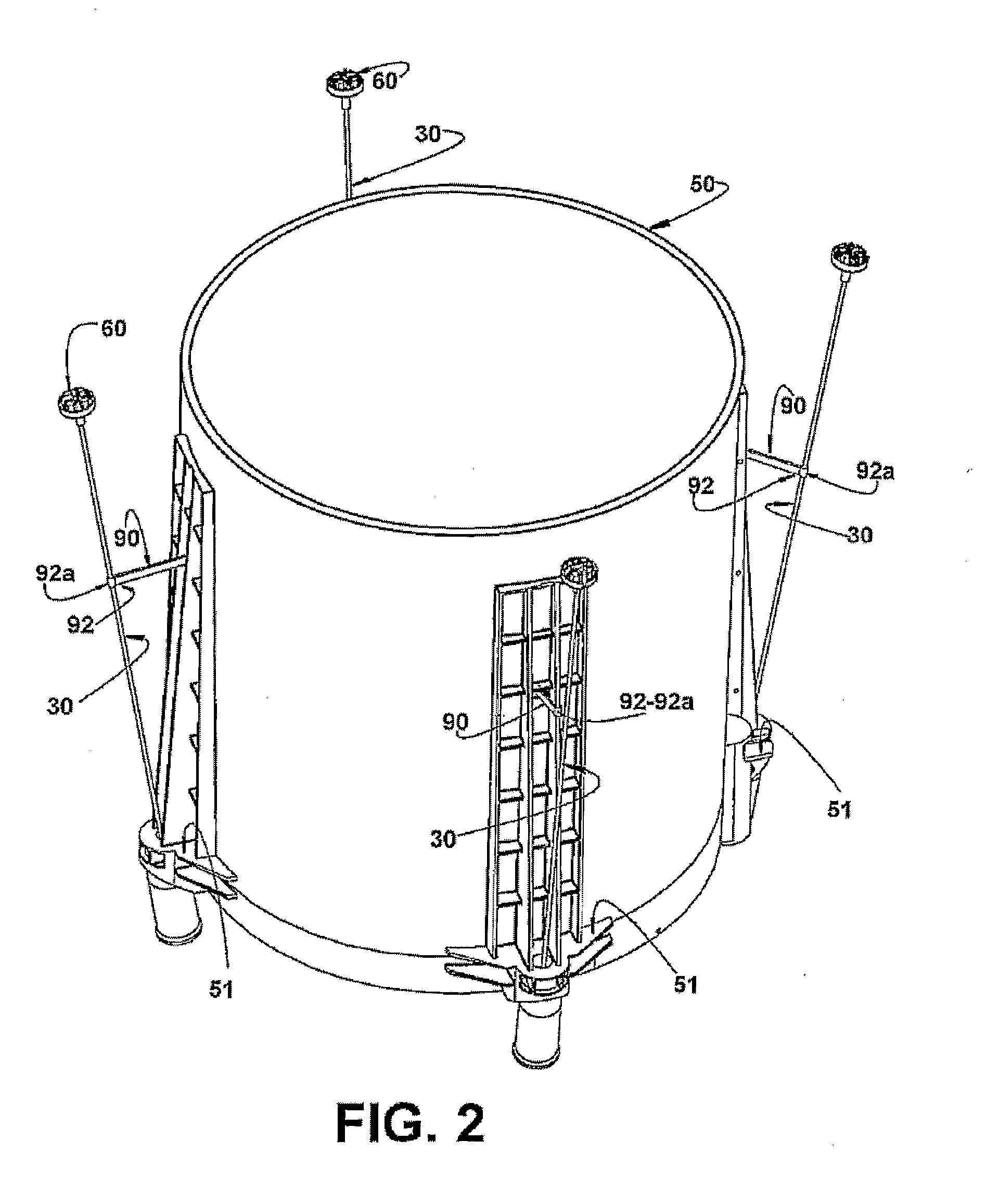

[0024]As mentioned above and also illustrated in the drawings appended hereto, the invention refers to a clothes washing machine, preferably top loading, but also to a front loading, horizontal shaft washing machine, said machine comprising a basic structural cabinet 10, generally defined by a tubular-shaped body, generally polygonal in section and to stand on a floor (not illustrated). The structural cabinet 10 can be built in different ways using different materials, but preferably, takes on the shape of a tubular body comprising a surrounding rib 10a, generally metal plates and, in the configuration illustrated, it is formed by portions of front, rear and opposed side walls.

[0025]The structural cabinet 10 incorporates, on top, generally next to the vertices of its polygonal transversal section, a horizontal rim 11, welded or otherwise fixed internally to the structural cabinet 10, next to the upper edge thereof, each horizontal rim 11 defining a support on which a respective susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com