Hand puller whose handle rolls in the strap

a technology of hand puller and handle, which is applied in the field of hand puller, can solve the problems of increasing material cost, long movable arm, increasing material cost, etc., and achieves the effect of more convenience and higher efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

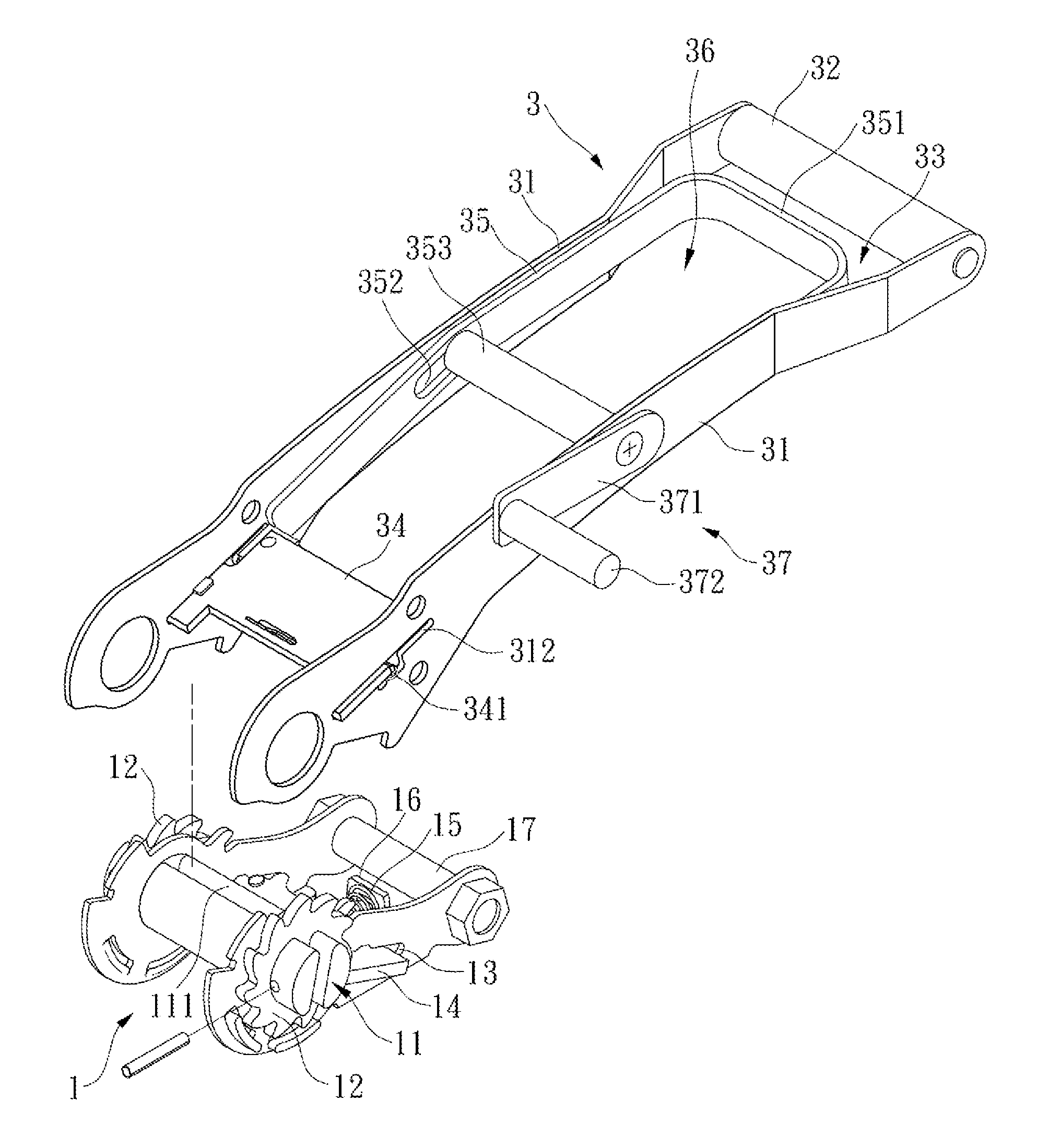

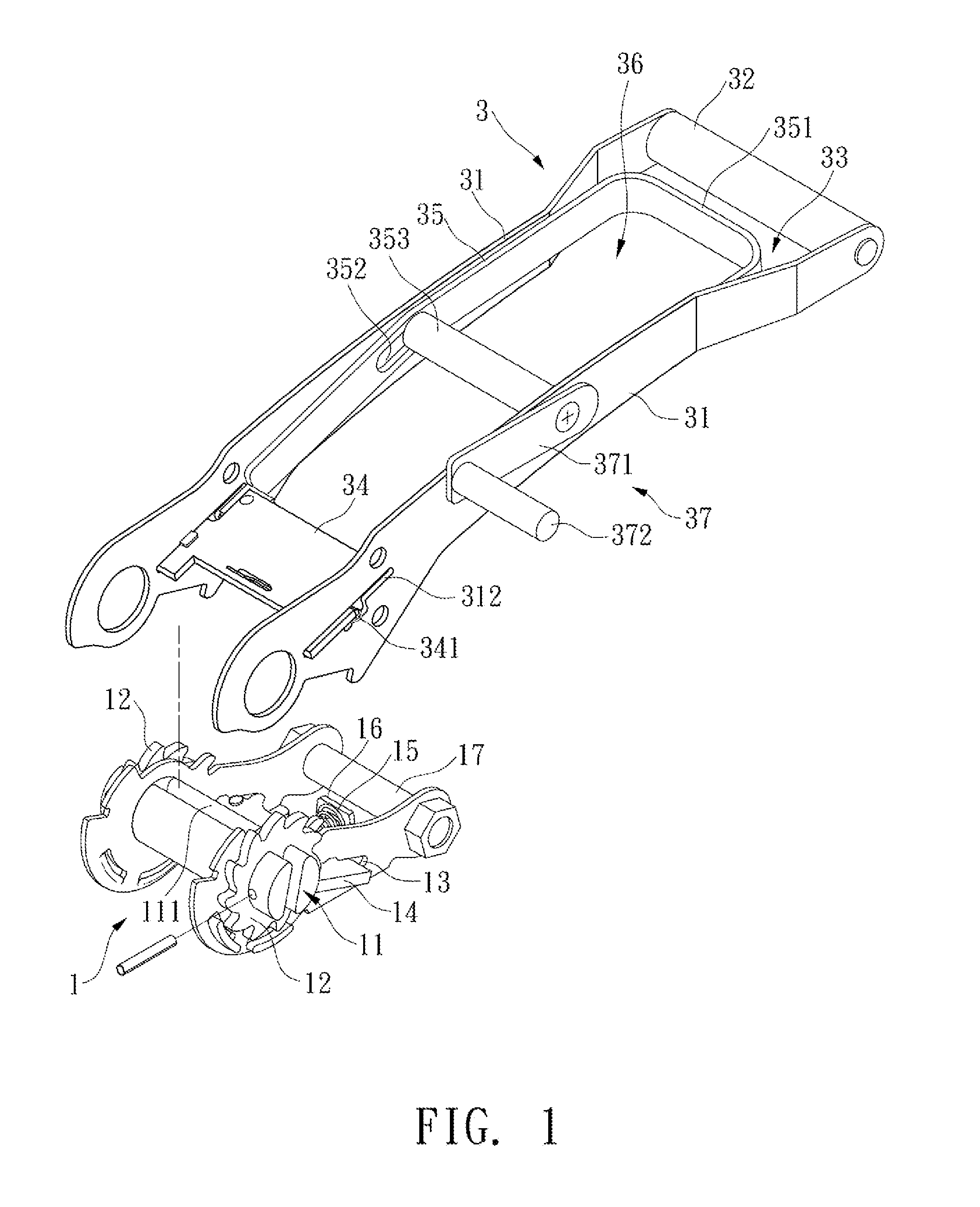

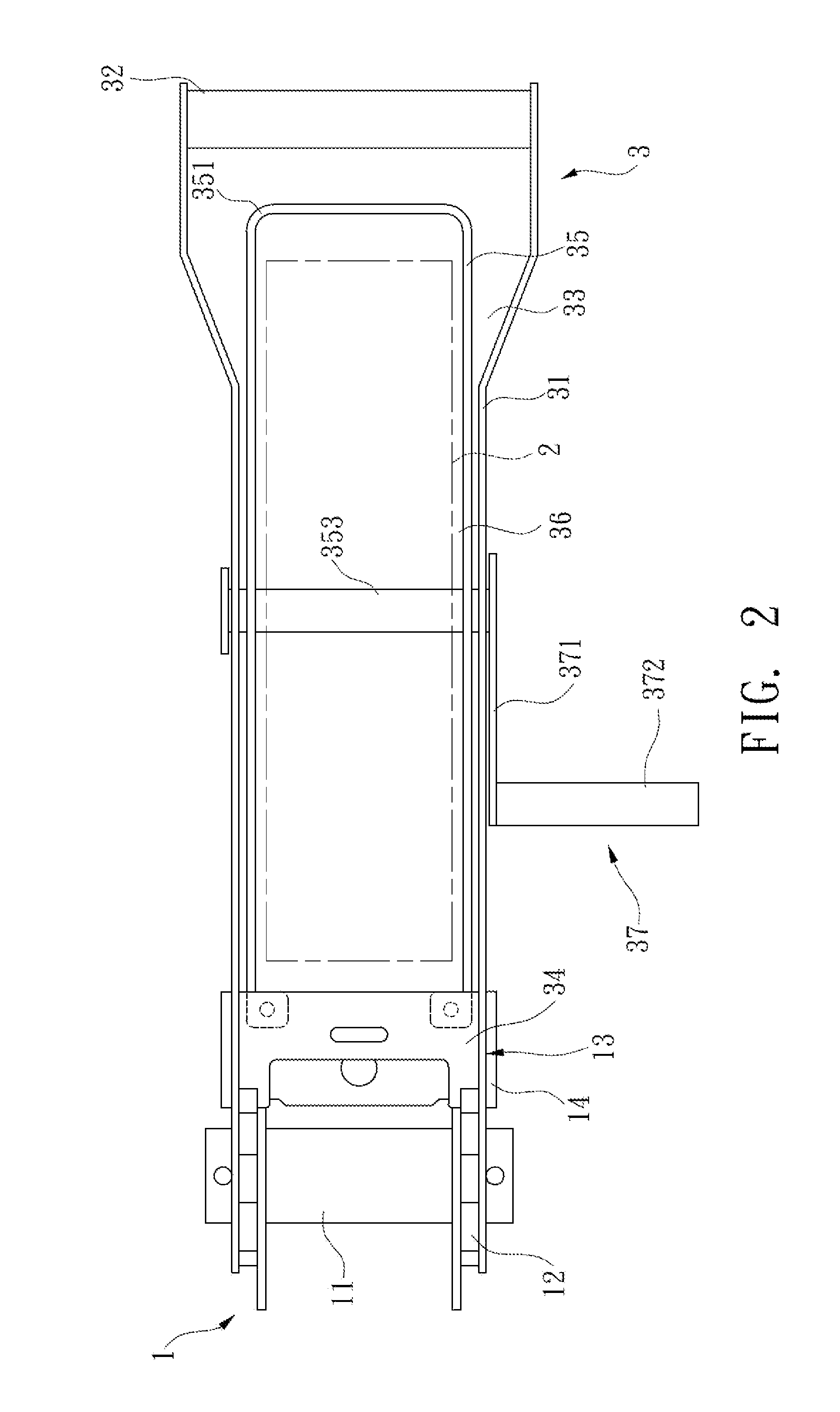

[0029]Please refer to FIGS. 1 to 4. The following paragraphs describe the invention. The embodiment includes a base 1 and a movable arm 3.

[0030]One end of the base 1 is pivotally connected with a pivotal element 11. The center of the pivotal element has a through hole 111 for a strap 2 to go through. The end parts of the pivotal element 11 going out of both sides of the base have respectively a ratchet wheel 12 rotating along with the rotating element 11. A first sliding groove 13 is formed on both sides of the base 1 near the two ratchet wheels 12. The two first siding grooves 13 is disposed with a first stopping plate 14 that can slide and urge against the two ratchet wheels 12. The side of the first stopping plate 14 far from the two ratchet wheels 12 is provided with a spring 15 for pushing the first stopping plate 14, so that the first stopping plate 14 urges against the two ratchet wheels 12. An extension board 16 is disposed between both sides of the bottom of the base 1. The...

second embodiment

[0037]Of course, the invention has many other embodiments that only differ in details. Please refer to FIG. 5 for the invention. The hand puller in this embodiment includes a base 4 and a movable arm 5.

[0038]One end of the base 4 is pivotally connected with a pivotal element 41. The center of the pivotal element has a through hole 411 for a strap 2 to go through. The end parts of the pivotal element 41 going out of both sides of the base have respectively a ratchet wheel 42 rotating along with the rotating element 41. A first sliding groove 43 is formed on both sides of the base 4 near the two ratchet wheels 42. The two first siding grooves 43 is disposed with a first stopping plate 44 that can slide and urge against the two ratchet wheels 42. The side of the first stopping plate 44 far from the two ratchet wheels 42 is provided with a spring 45 for pushing the first stopping plate 44, so that the first stopping plate 44 urges against the two ratchet wheels 42. An extension board 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com