Sandwich element for the sound-absorbing inner cladding of means of transport, especially for the sound-absorbing inner cladding of aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

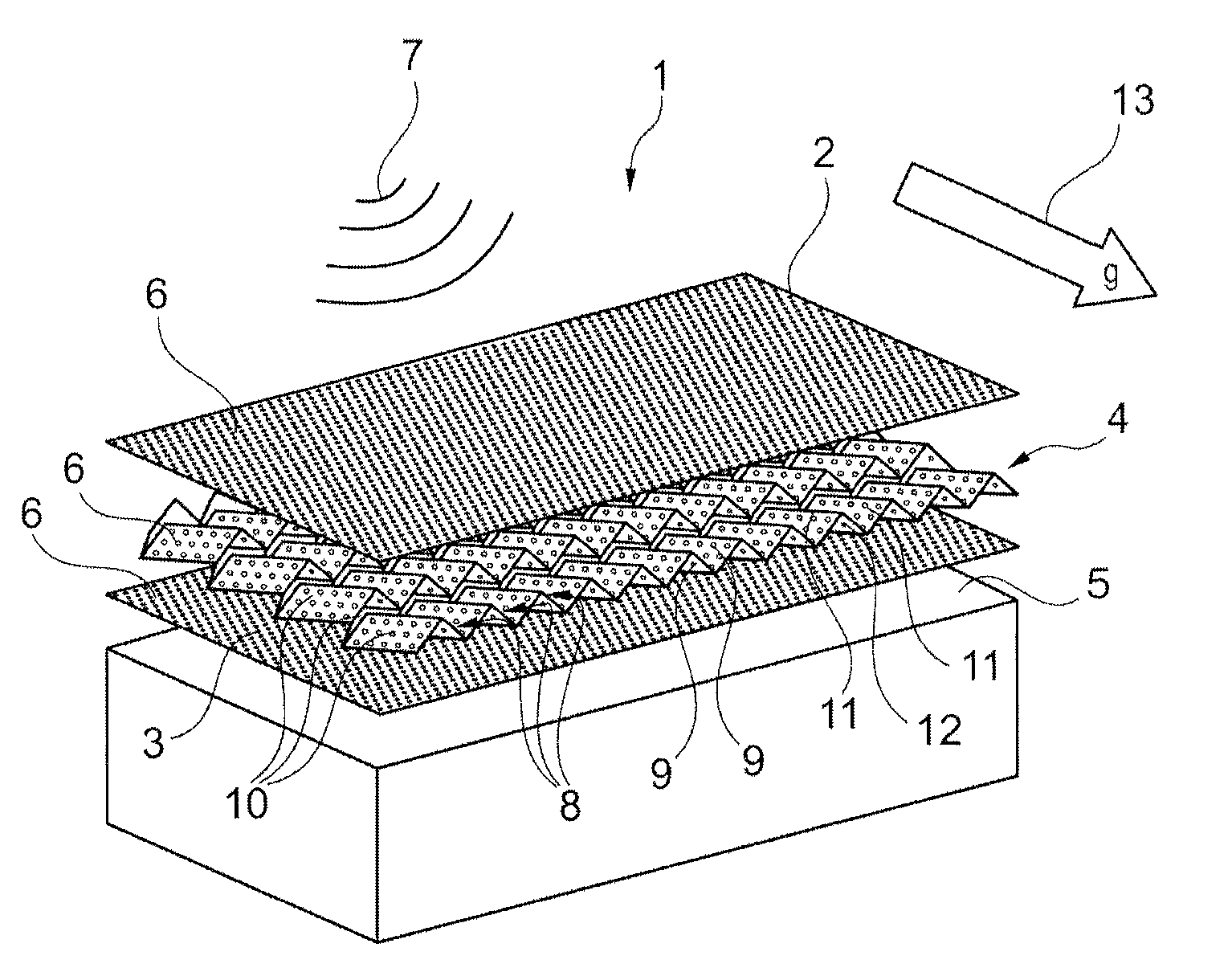

[0037]FIG. 1 shows an isometric diagram of a sandwich element according to the invention. A sandwich element 1 comprises, amongst other things, two cover layers 2, 3 which are applied to both sides of a core structure 4. Applied to the side of the cover layer 3 facing away from the core structure 4 is a sound absorption layer 5 to achieve the desired high sound absorption effect of the sandwich element 1. In addition, the sound absorption layer 5 also enhances the heat insulating capacity of the sandwich element 1 according to the invention.

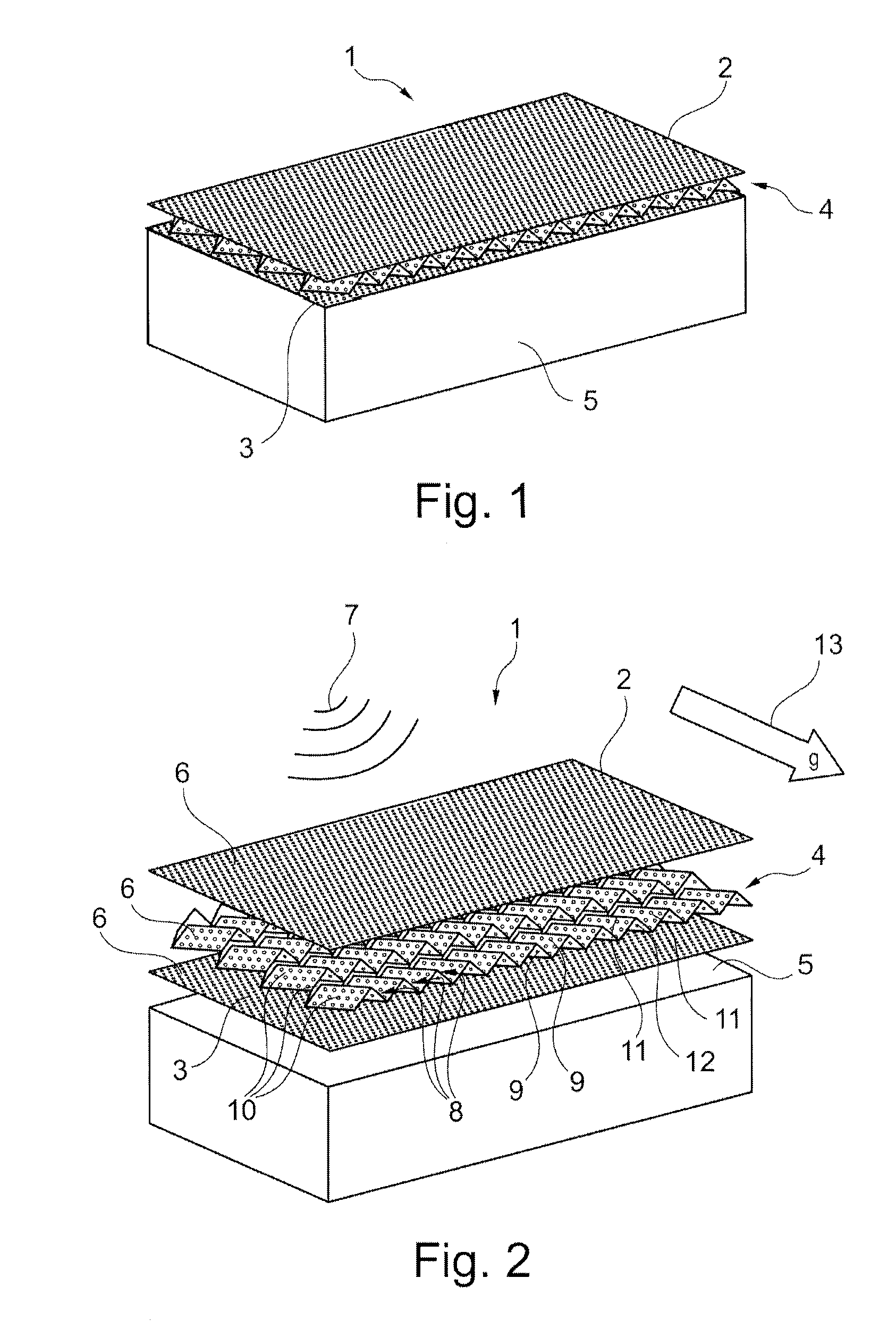

[0038]FIG. 2 shows an isometric exploded diagram of the sandwich element according to the invention.

[0039]The sandwich element 1 comprises, amongst other things, the core structure 4 with the cover layers 2, 3 applied to both sides. The sound absorption layer 5 is applied to the lower side of the cover layer 3. A plurality of passages 6 are incorporated both in the cover layers 2, 3 and also in the core structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com