Quick release bench vise system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

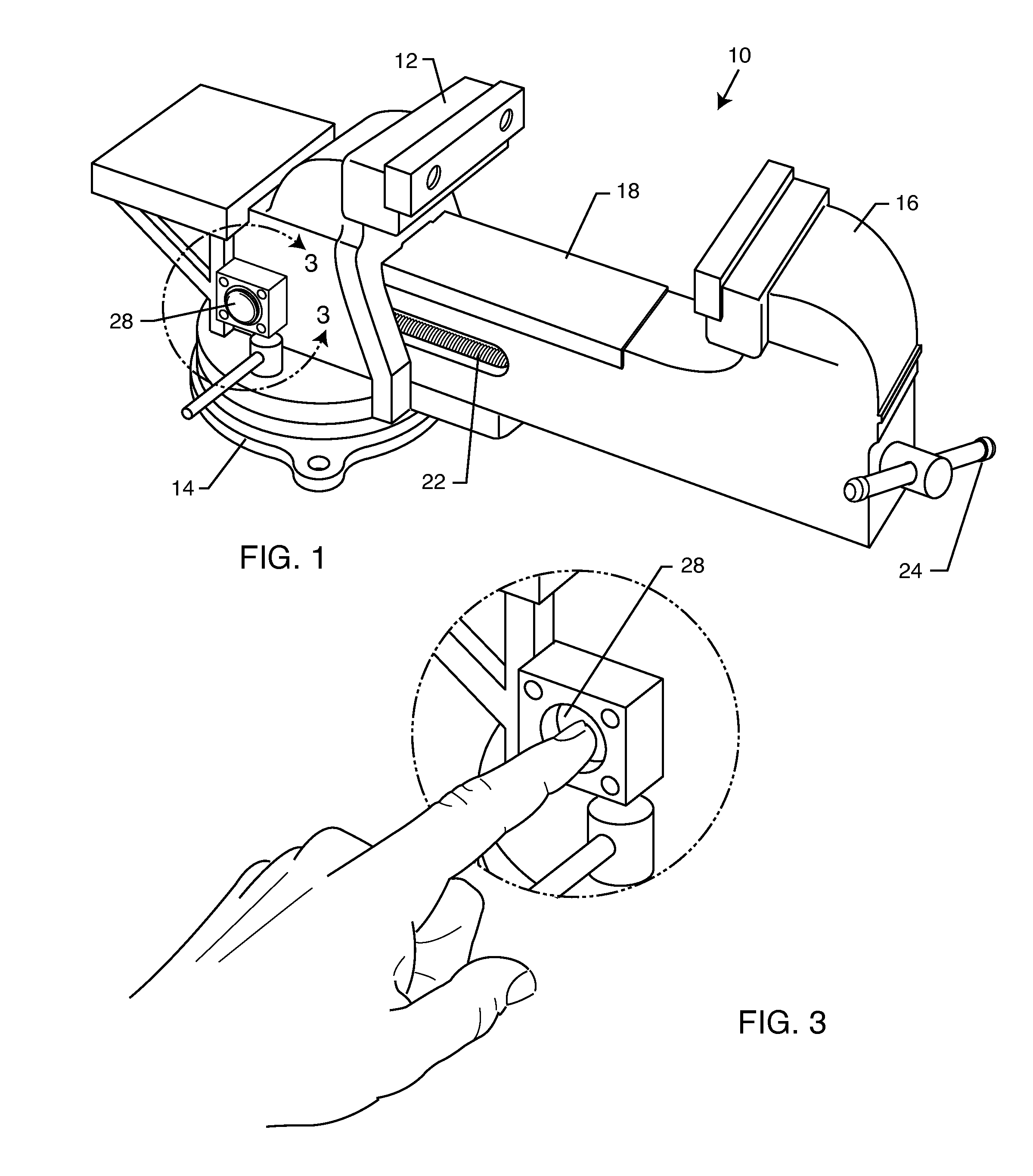

[0021]FIG. 1 illustrates a perspective view of an exemplary quick release bench vise 10 which embodies the present invention. The vise 10 includes a first jaw 12 which can be fastened to a work bench or table through its flat base 14 using screws, bolts, C-clamps, or any other suitable fastening technique. As with most bench vises, the first jaw 12 can also be rotated and locked into place using conventional methods. A second jaw 16 is moveable relative to the first jaw 12. In this embodiment, the second jaw 16 has an elongated arm 18 which translates within a passageway 20 through the first jaw 12, allowing the jaws to come together to hold a work piece therebetween.

[0022]Rotatably fixed to the second jaw 16 is a threaded shaft 22. The threaded shaft 22 is parallel to the elongated arm 18 and also resides within the passageway 20 of the first jaw 12. The threaded shaft 22 may be rotated with a traditional handle 24 attached to the threaded shaft 22 on an end extending from second j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com