Rotary undercutter for rail line maintenance

a technology of undercutting and rail line, which is applied in the direction of ballastway, construction, and way, etc., can solve the problems of reducing the draining ability or supporting ability of ballast, reducing the efficiency of plow or sled, and limited plow or sled approach to remove ballast, so as to reduce the downtime associated with plow positioning and flexibility. the effect of the greater degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

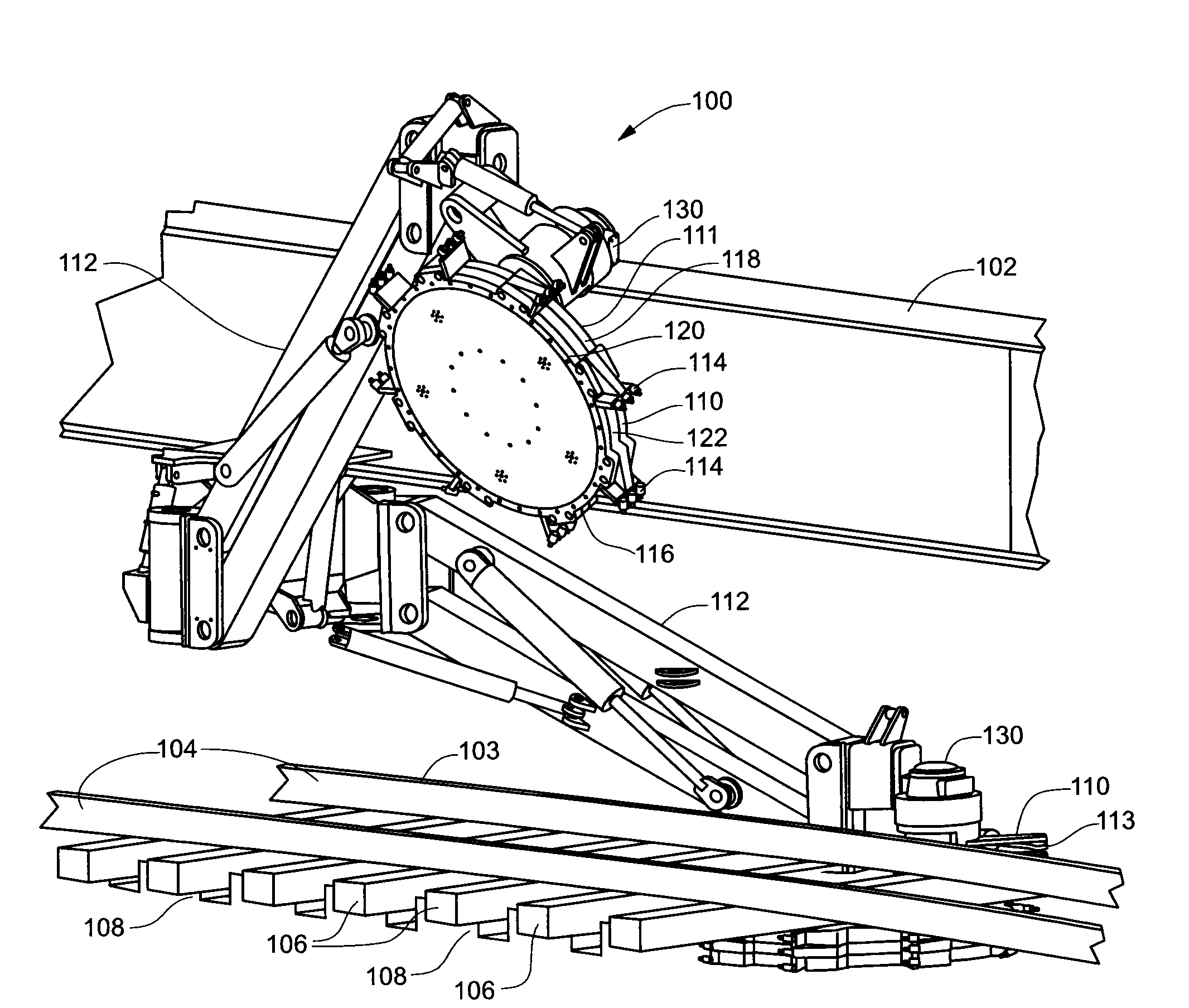

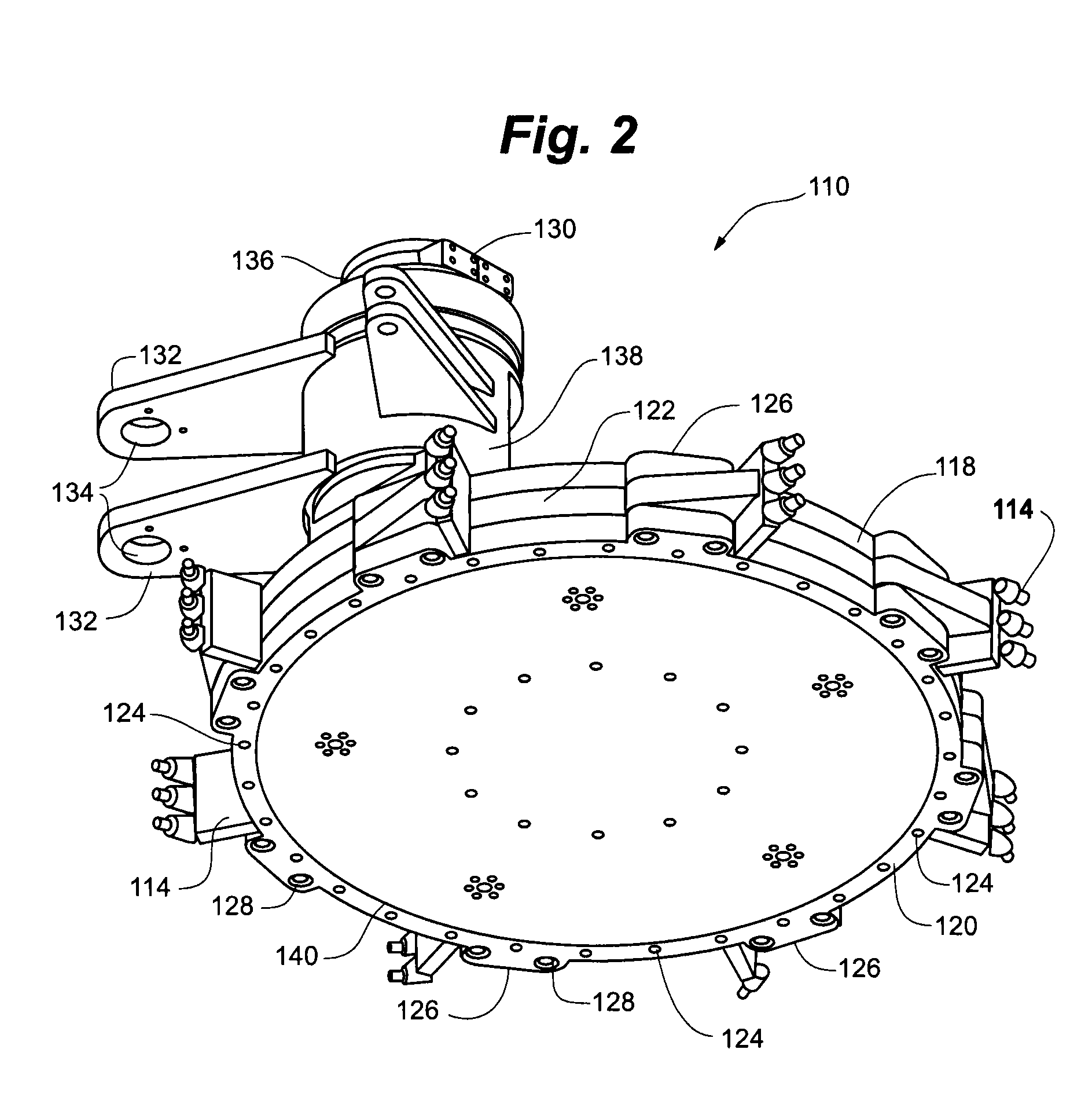

[0035]As shown in FIG. 1, a representative embodiment of a rotary undercutter 100 is shown mounted to a support structure 102 suspended between two railcar carriages (not depicted). The rotary undercutter 100 is suspended above a rail line 103 including pair of rails 104 and rail ties 106 that have been lifted above their ballast 108. As shown in FIG. 1, rotary undercutter 100 can include a pair of cutting wheel assemblies 110 with one shown disposed in an elevated position 111 while the other is shown in an operating position 113 below the rails 104. Each cutting wheel assembly 110 is individually manipulated and positioned by a corresponding multi-jointed positioning arm 112. The positioning arms 112 can include a non-limiting variety of hinges, couplings, joints, sliding mechanisms, actuators, hydraulics, motors, or the like, as needed to mount the cutting wheel assemblies 110 to support structure 102 or alternatively, directly to a vehicle and to allow the cutting wheel assembli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com