Ice Drill

a drill and ice technology, applied in the field of ice drills, can solve the problems of considerable cost saving and the like, and achieve the effect of broadening the field of use of ice drills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

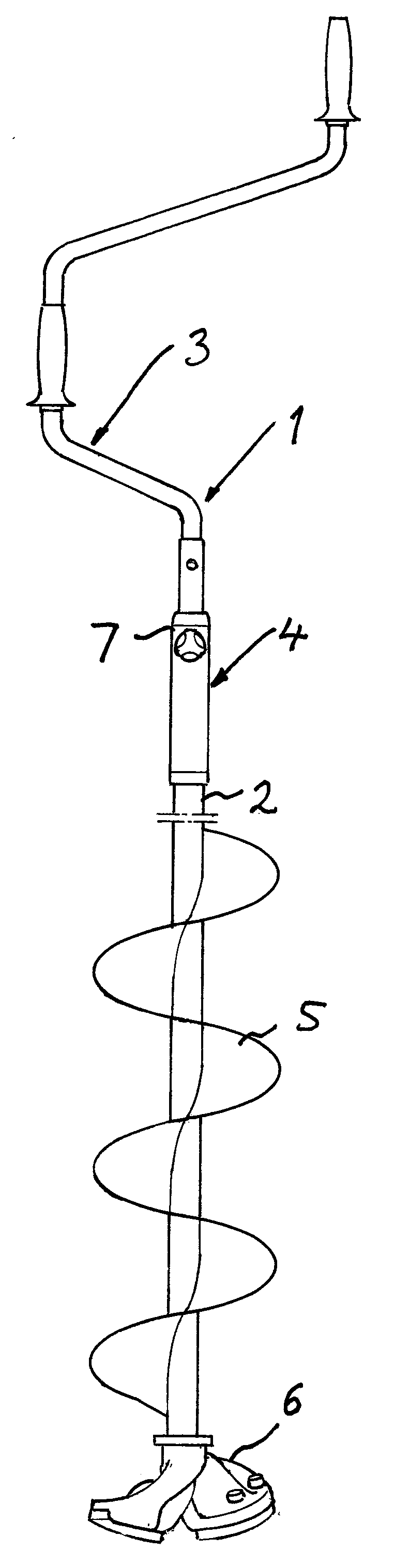

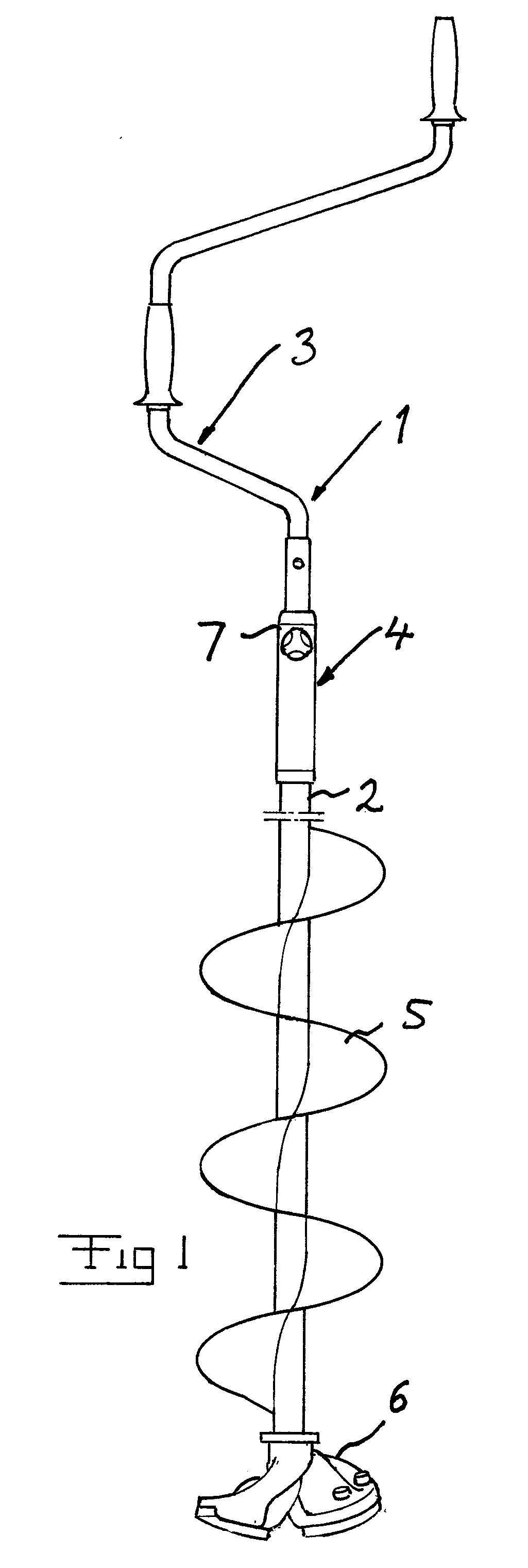

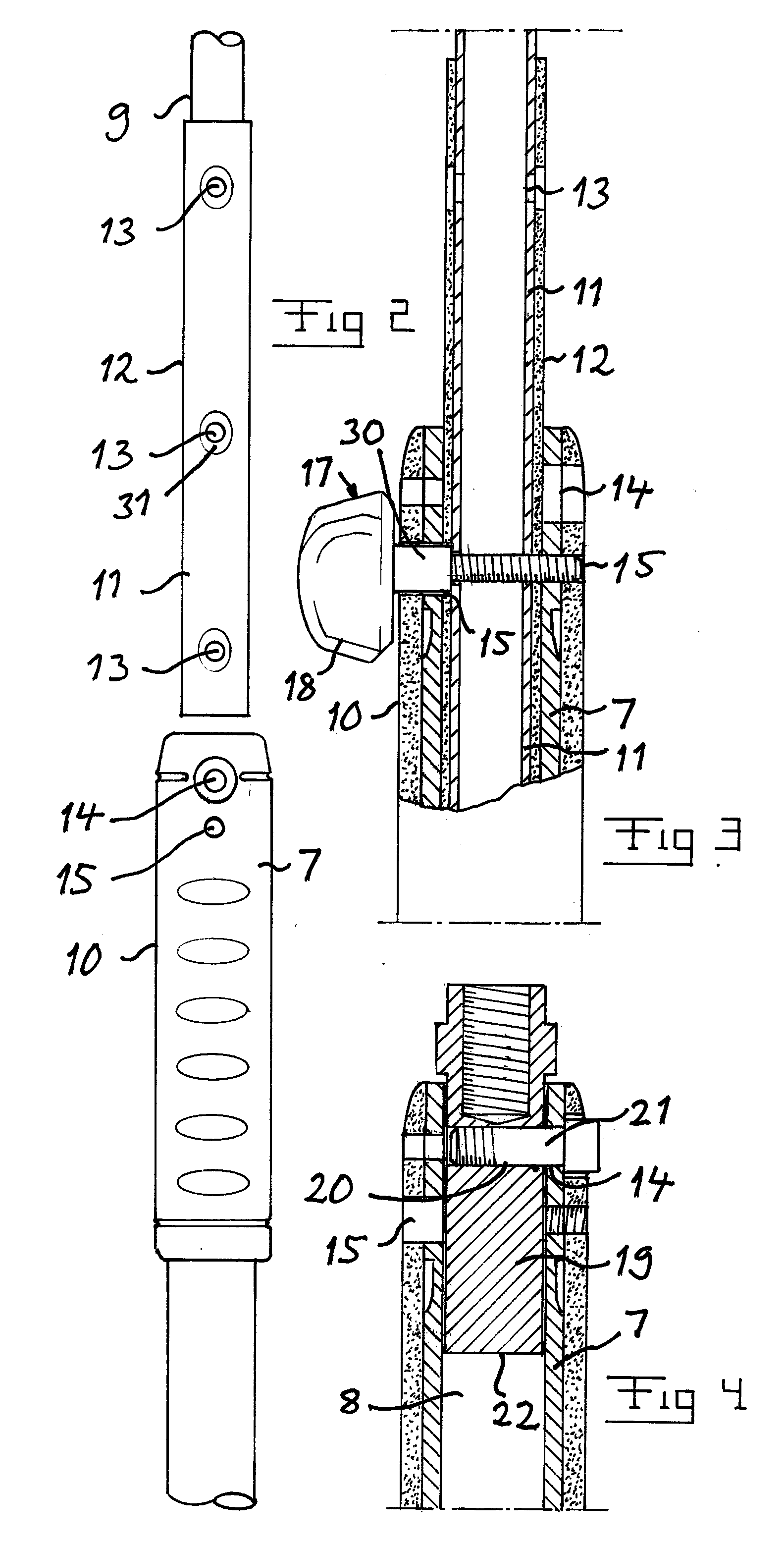

[0030]An ice drill 1 according to an embodiment of the present invention is illustrated in FIG. 1. This has a central rigid drill rod 2, which for example is made of stainless steel or surface treated steel. A crank 3 is removably secured to the upper part of the drill rod through a device 4 according to the invention for making it possible to by hand power drive the drill rod 2 to rotate around the axis thereof for drilling. A spiral 5 extends around the drill rod from the region of a bore crown 6 and upwards for lifting crushed ice formed by drilling. The device 4 for connecting the crank 3 with the drill rod 2 constitutes the very core of the invention and will now be described while simultaneously referring to FIGS. 2-4. The drill rod end 7 is hollow and has an inner cavity 8 with a larger diameter than the outer diameter of the crank rod 9 itself. The drill rod end 7 is provided with a handle arranged externally thereof for providing a hand grip when releasing or loosening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com