Rotor Lock for a Wind Turbine

a technology of rotating locking and wind turbine, which is applied in the direction of propellers, propulsive elements, water-acting propulsive elements, etc., can solve the problems of unreliable rotational locking, difficult and relatively expensive hub manufacturing, and inability to use the locking mechanism directly for absorbing tilt or yaw loads, etc., to achieve the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

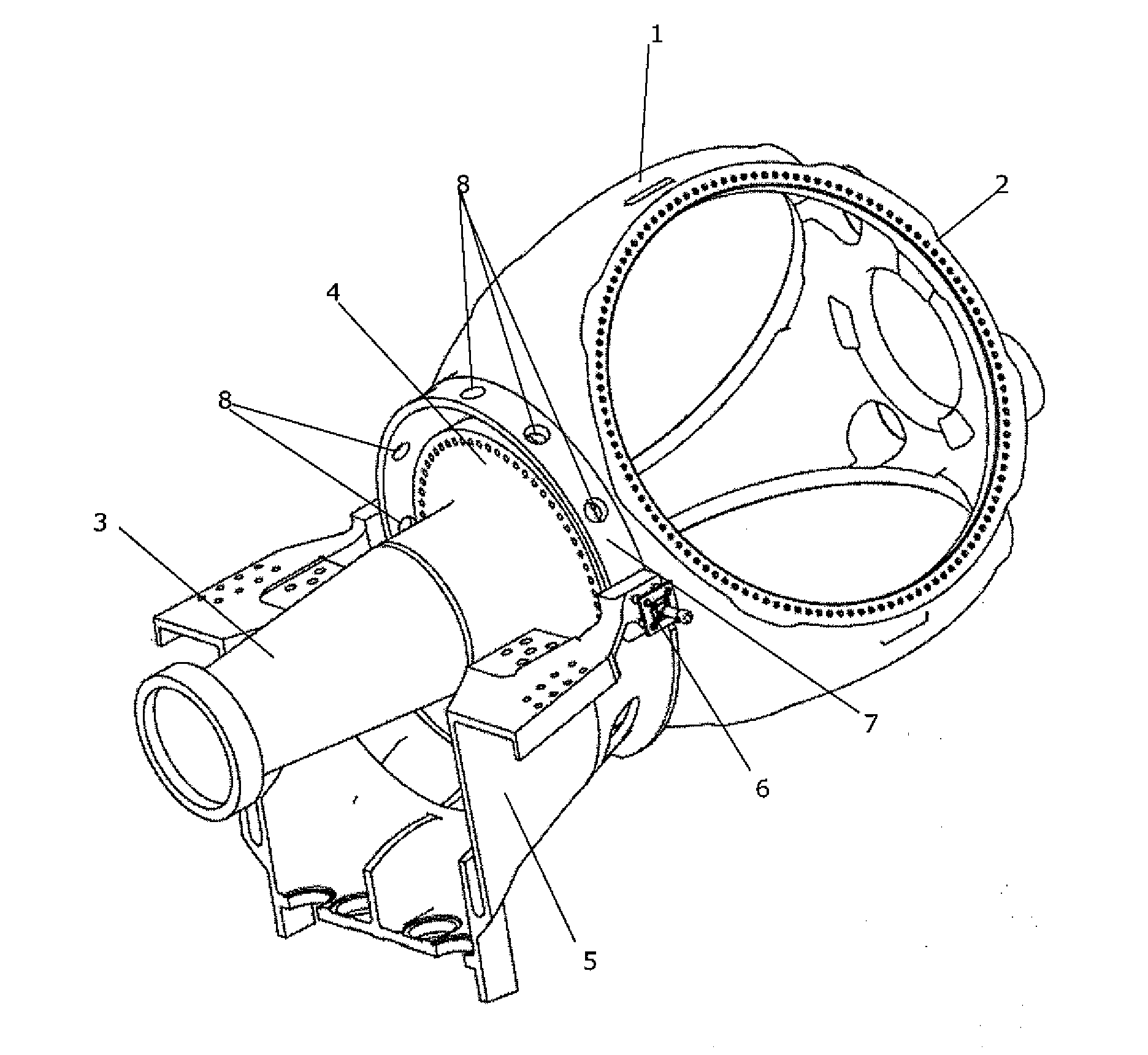

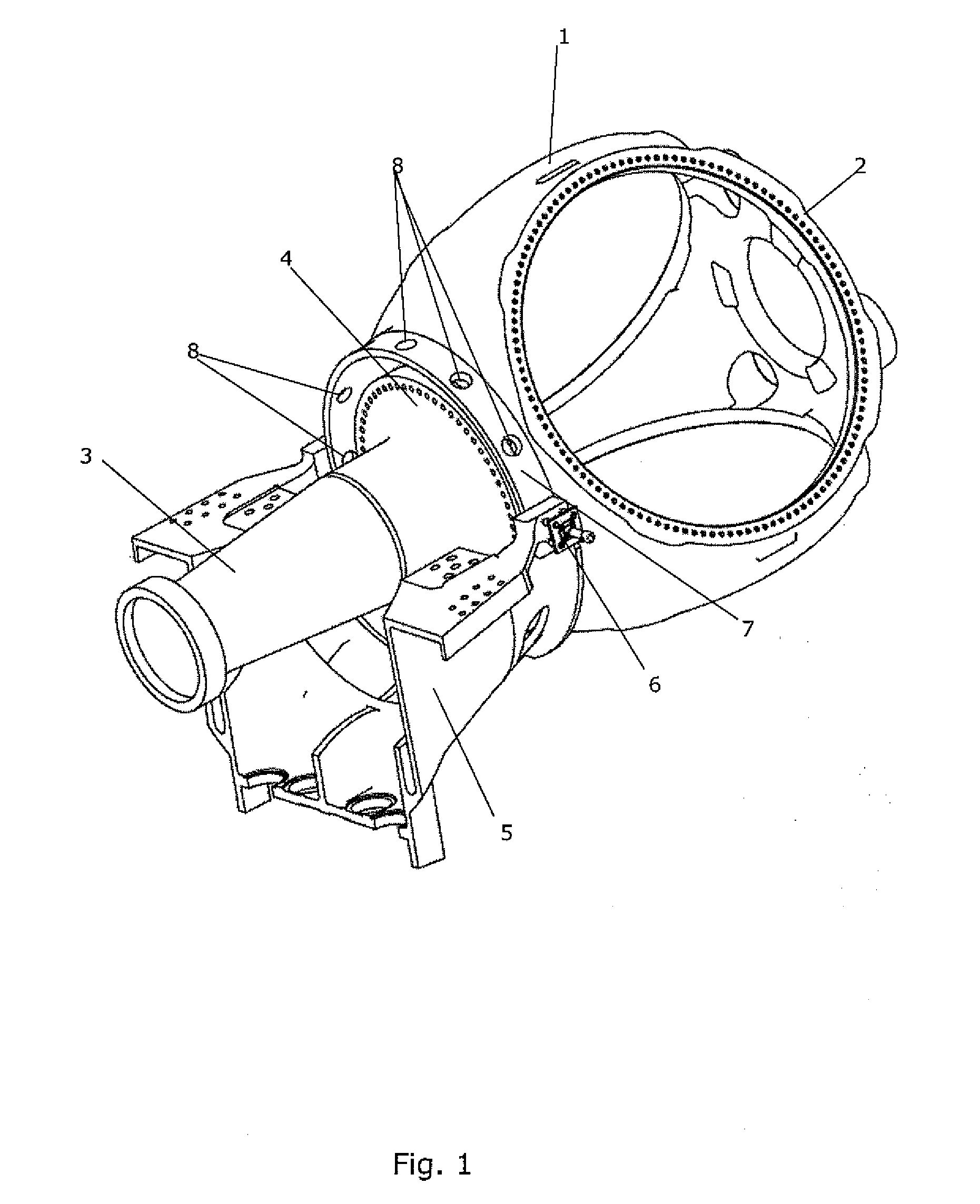

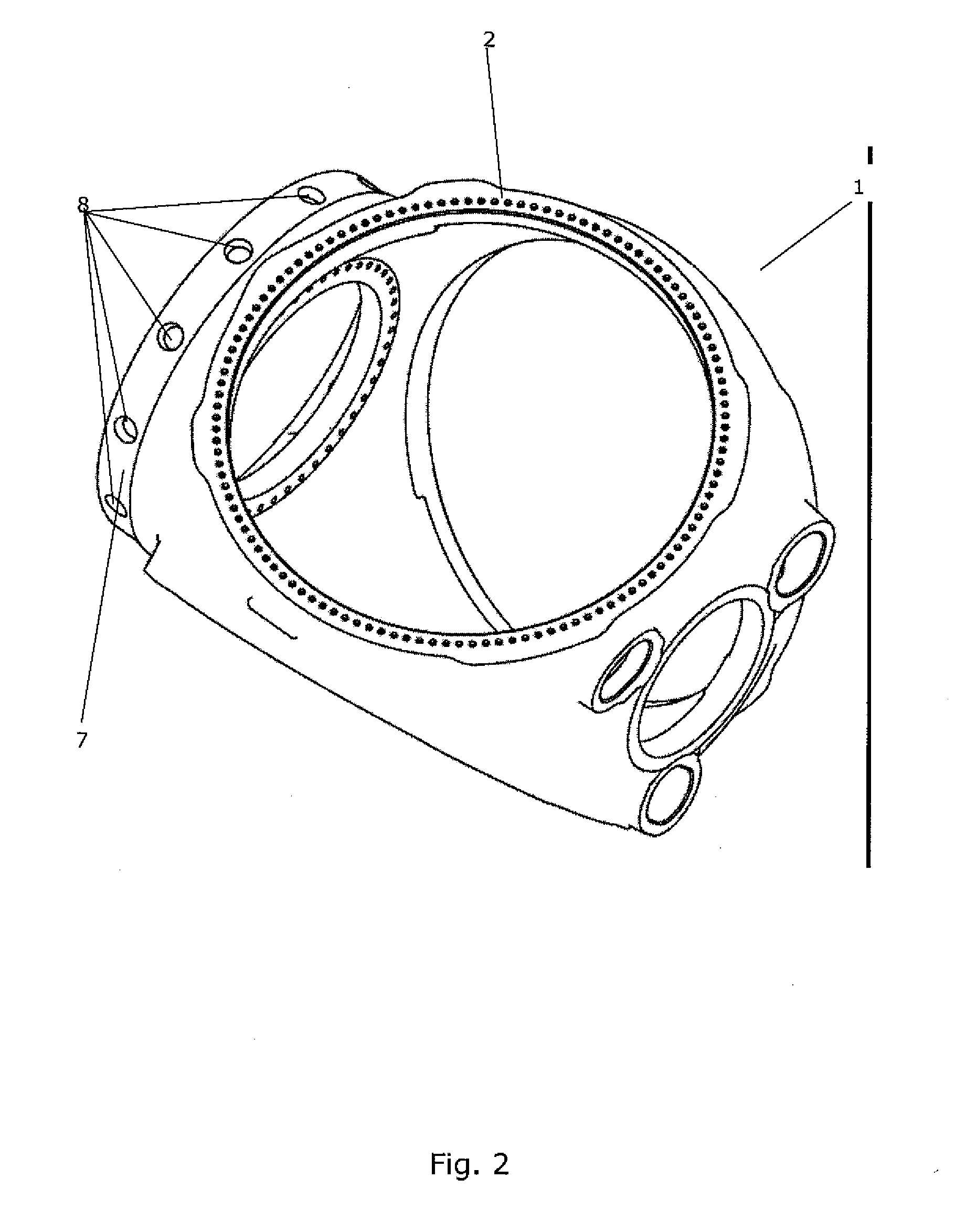

[0008]It is an object of the invention to provide a locking arrangement for a hub of a wind turbine which is capable of preventing rotational movements of the hub as well as tilt and / or yaw movements of the hub.

[0009]It is a further object of the invention to provide a locking arrangement for a hub of a wind turbine which is capable of preventing rotational movements of the hub during removal or replacement of the main shaft.

[0010]It is an even further object of the invention to provide a locking arrangement for a hub of a wind turbine in which rotational locking of the hub is more reliable than the locking provided by prior art locking arrangements.

[0011]It is an even further object of the invention to provide a locking arrangement for a hub of a wind turbine, wherein the locking arrangement is easier and more cost effective to manufacture than prior art locking arrangements.

[0012]According to the invention there is provided a locking arrangement for a hub of a wind turbine, said h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com