Additive compositions for correcting overtreatment of conductivity additives in petroleum fuels

a technology of conductivity additives and additive compositions, applied in the field of additive compositions, can solve the problems of static charging, and low sulfur content of fuels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0084]Conductivity Test Method: Conductivity of the fuel is measured by using procedures outlined in ASTM D-2624 Standard Test Methods for Electrical Conductivity of Aviation and Distillate Fuels. The complete method is incorporated herein by reference.

Conductivity Correcting Additive Test Method:

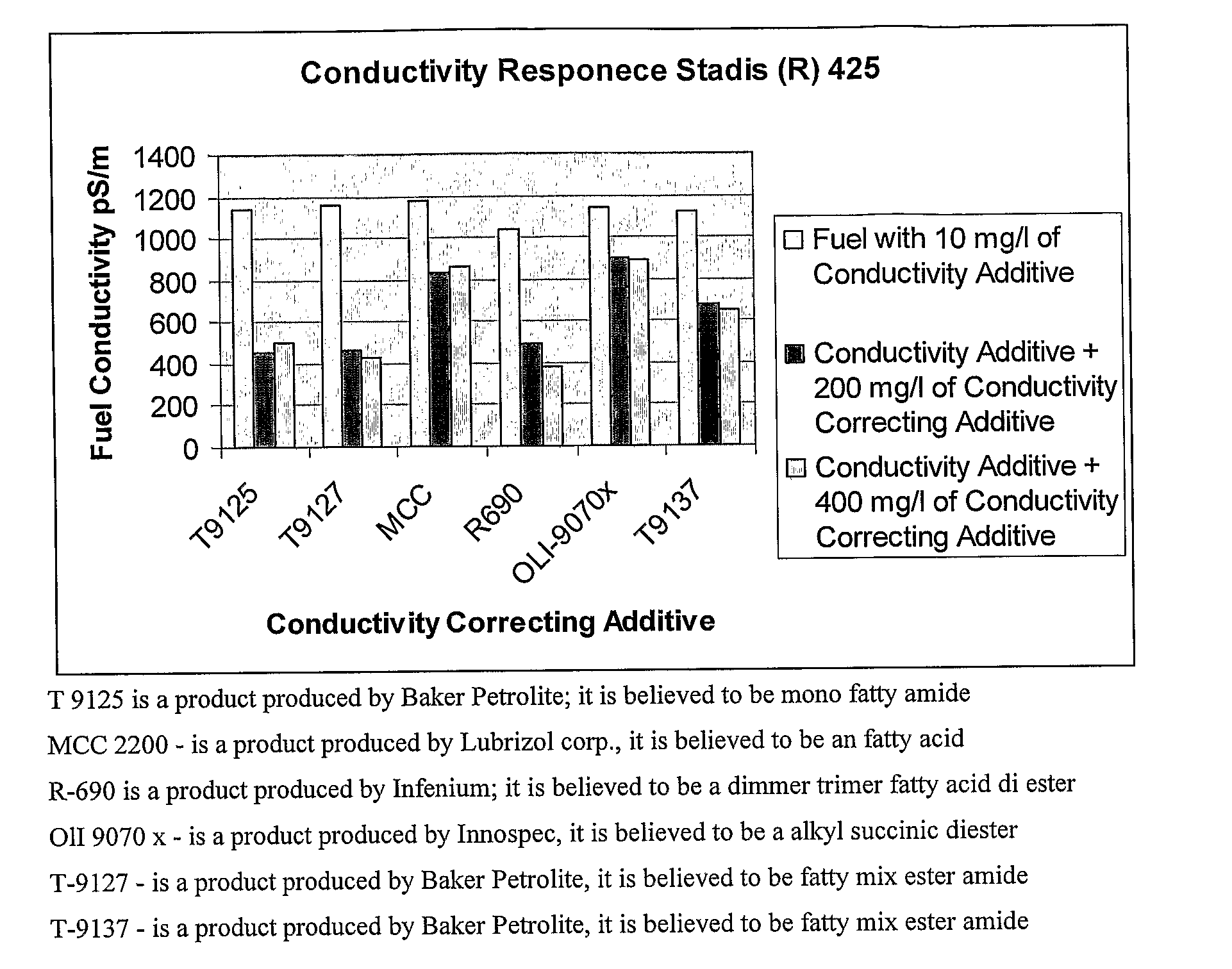

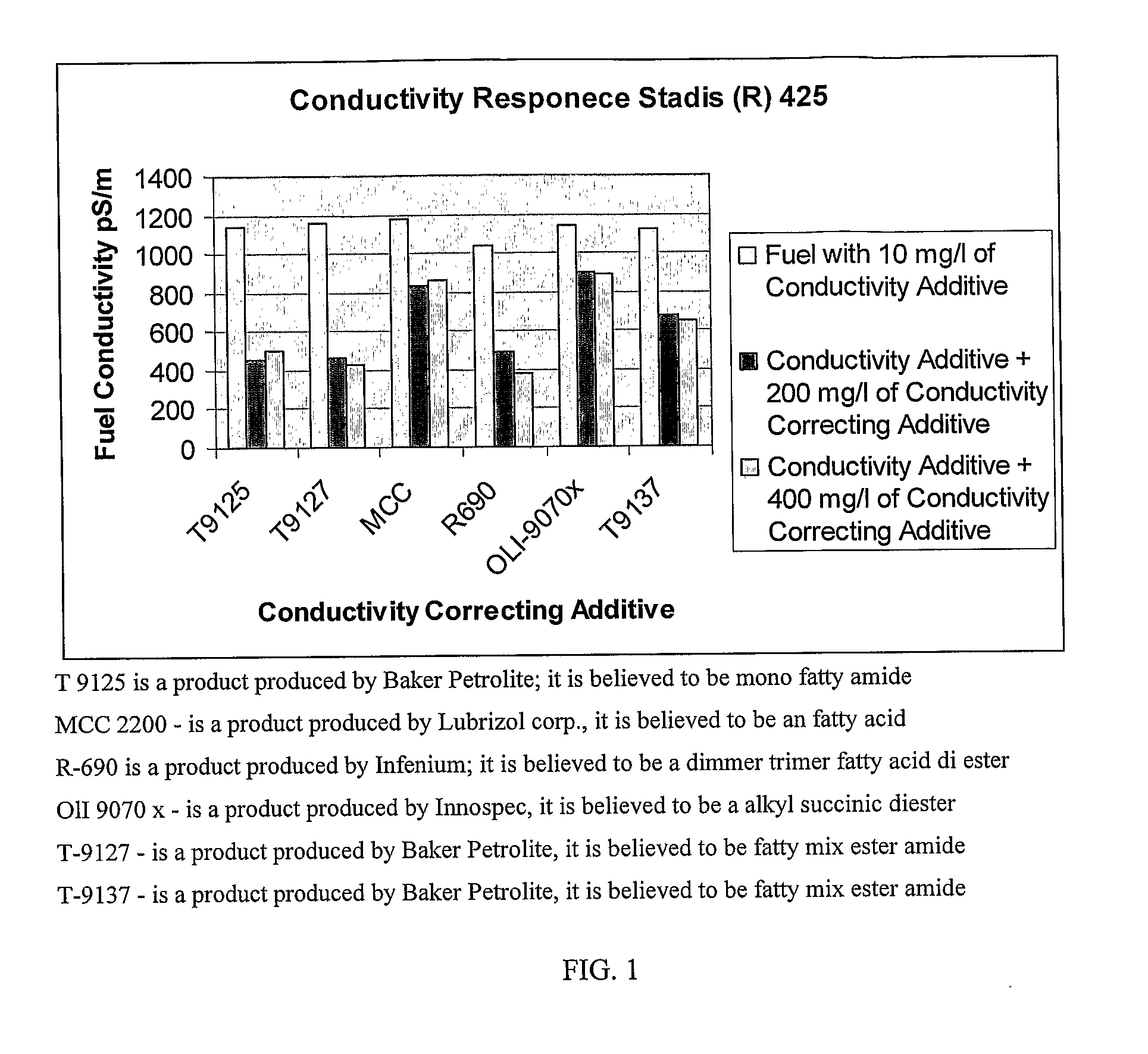

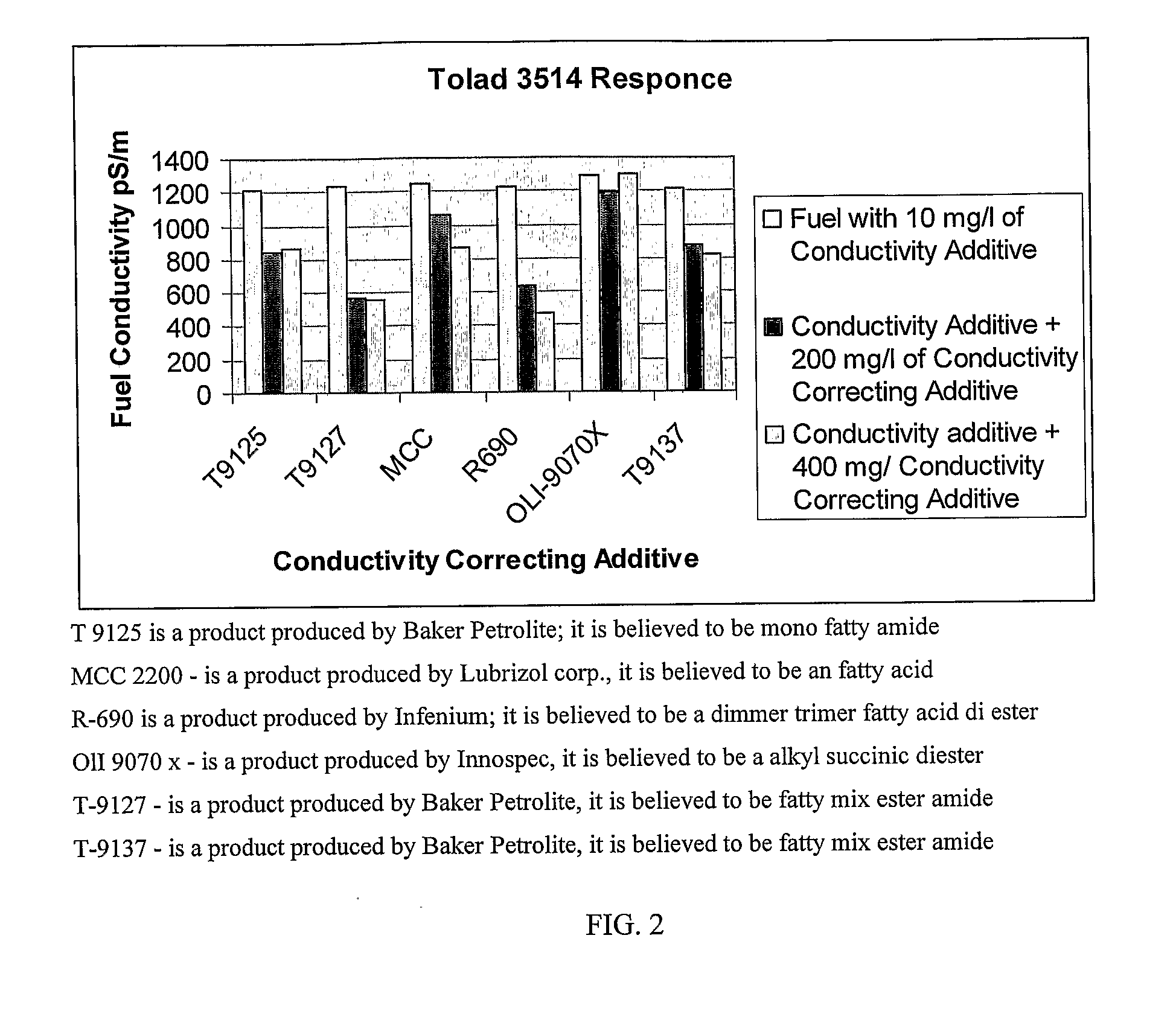

[0085]General Additive Survey: The effect on conductivity upon combining other fuel additives with conductivity additives was evaluated. A series of additives available in the fuel industry were added to #2 ULS Diesel containing 1 mg / l of market available conductivity additives. The additives which exhibited the greatest conductivity control response were then reevaluated at higher doses of conductivity additive.

[0086]Conductivity Correcting Additive Screen: The base line conductivity of the fuel containing 10 mg / l of conductivity additive was measured. The additives selected from the General Additive Survey were then dosed into a high conductivity fuel (10 mg / l of conductivity additive) at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com