Articulated dump truck

a dump truck and articulation technology, applied in the direction of vehicle springs, towing devices, vehicles, etc., can solve the problems of failure to recognise the significant benefits conferred by such a system, and achieve the effect of improving the ride performance of the vehicle, sufficient resistance to roll movement, and increasing roll complian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

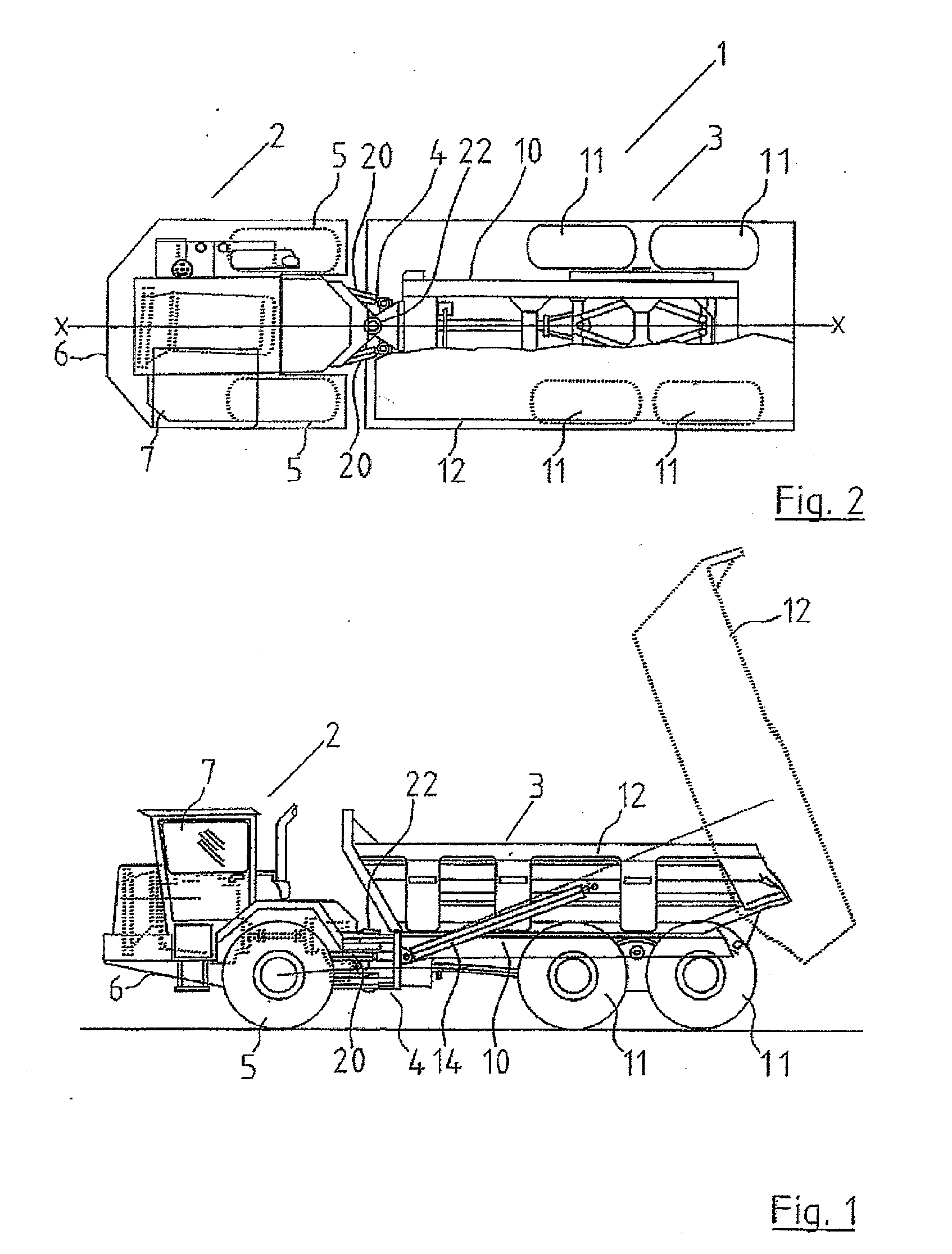

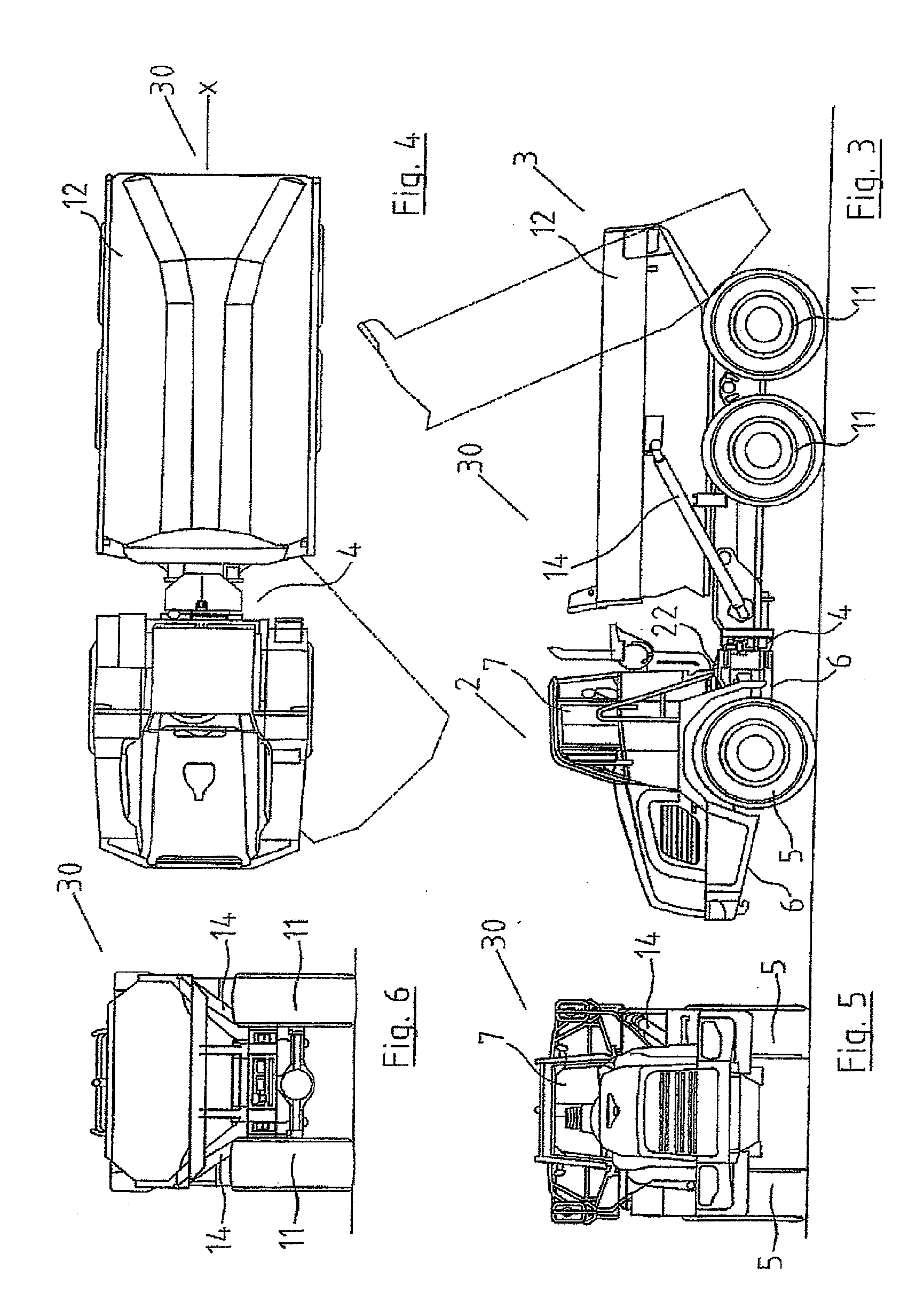

[0067]Referring to the drawings, and initially to FIGS. 1 and 2 thereof, there is illustrated an articulated dump truck vehicle according to the invention indicated generally by the reference numeral 1. The articulated dump truck 1 includes a front tractor unit 2 connected to an associated rear trailer unit 3 by an articulated coupling 4. The front tractor unit 2 is provided with an independent suspension system for mounting wheels 5 on a front chassis 6 of the front tractor unit 2.

[0068]The front tractor unit 2 has a cab 7 within which are located controls for driving and operation of the articulated dump truck 1.

[0069]The rear trailer unit 3 has a rear chassis 10 mounted on two pairs of wheels 11. A tipping container 12 is pivotaly mounted on the rear chassis 10 on which it can be tipped as shown in broken outline in FIG. 1 by means of rams 14 at each side.

[0070]The articulated coupling 4 can rotate about longitudinal axis X and vertical axis 22 of the truck 1 but is unable to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com