Small batch deep fryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

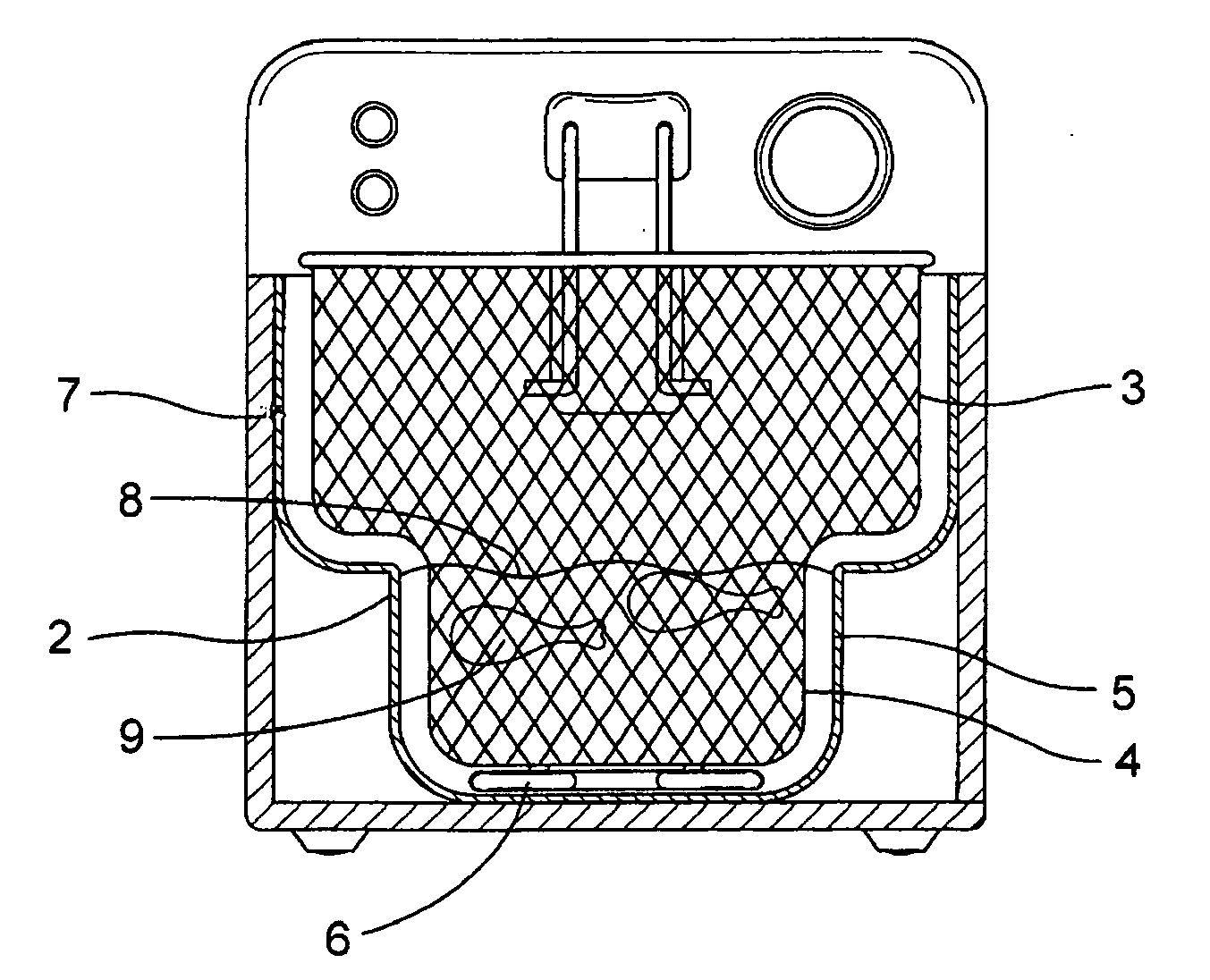

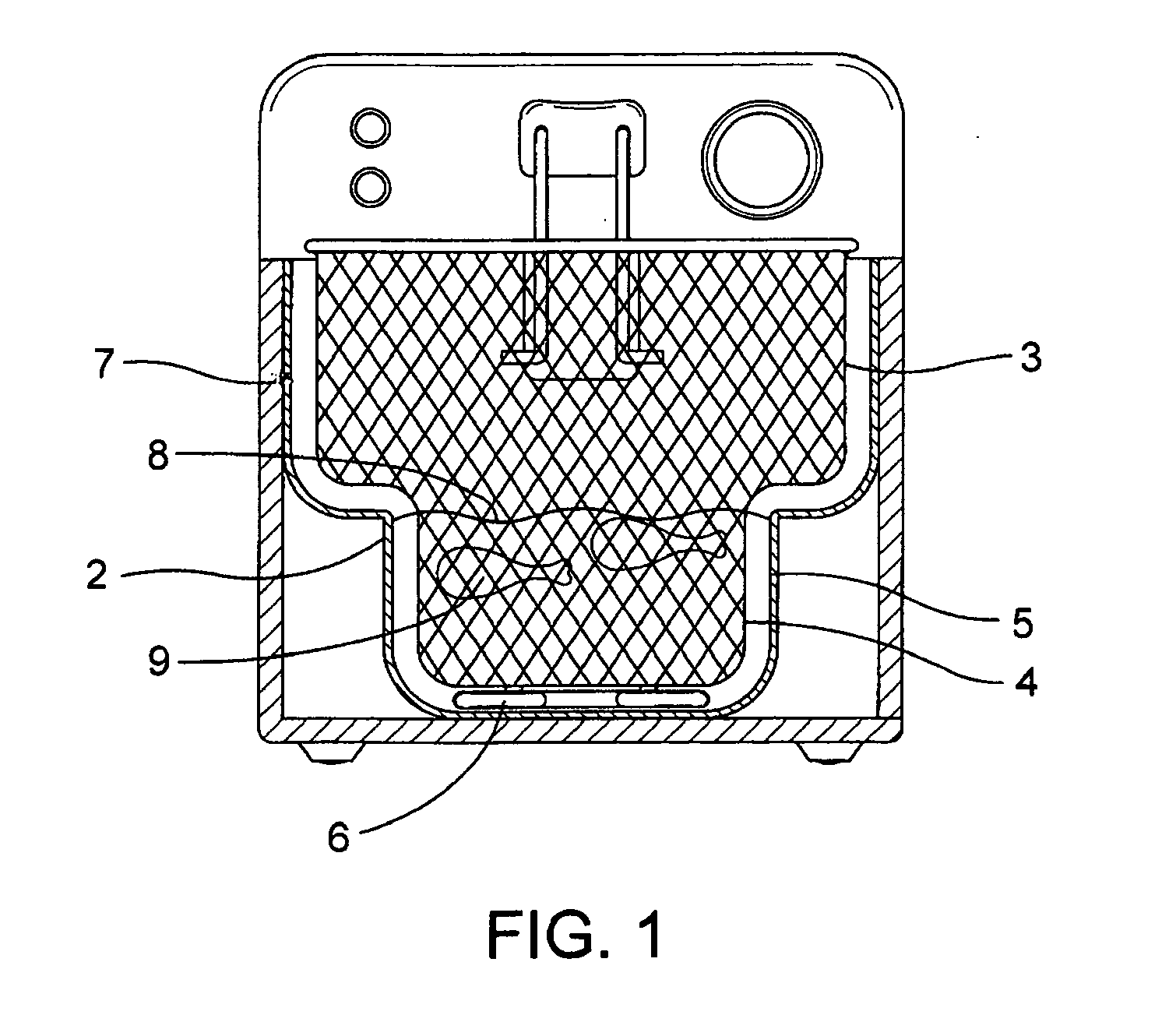

[0027]As shown in FIG. 1 a front cut away depicts the oil pot 2 and food basket 3 with their lower portions or small batch area 5 and 4 respectively smaller in cubic are than their upper portions. As shown the oil level 8 at the top of the recessed area of the oil pot 2 and food basket 3 and food 9 is shown in the smaller cubic area of the food basket 3. A heating element 6 is shown in the smaller cubic area of the oil pot 5. The deep fryer housing is depicted in 7.

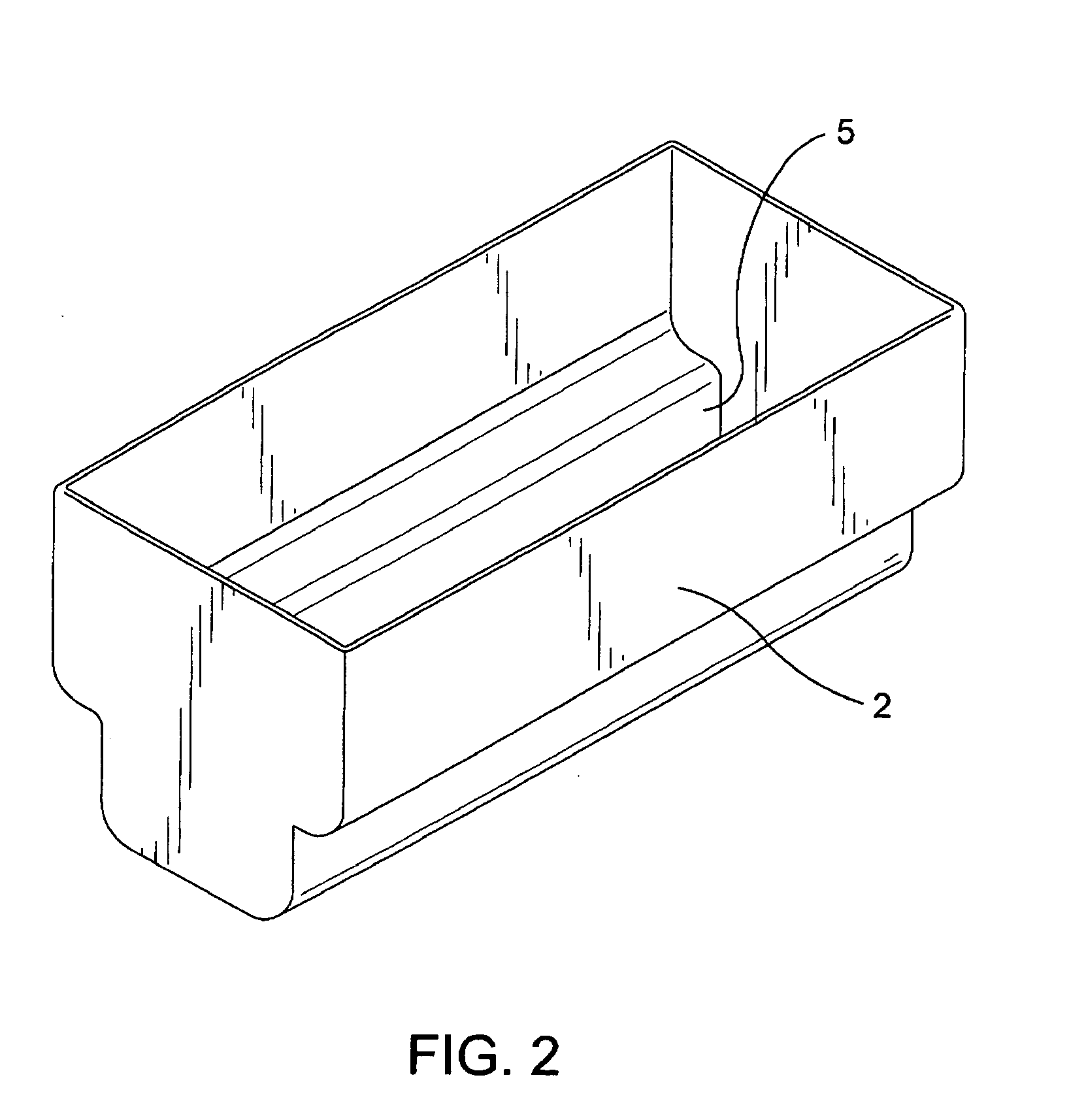

[0028]As shown in FIG. 2 the oil pot 2 and the reduced cubic area of the oil pot 5.

[0029]As shown in FIG. 3 the food basket 3 and the reduced cubic area of the food basket 4.

[0030]As shown in FIG. 5 the deep fryer as a complete entity 1.

[0031]As shown in FIG. 6 the deep fryer 1 as a an exploded view and sectional cut away depicting the food basket 3 and the lower smaller cubic area of the food basket 4 and the manner in which it fits into the oil pot 2 and the manner in which the smaller cubic area of the food basket 4 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com