Control moment gyroscope

a control moment and gyroscope technology, applied in the direction of instruments, cosmonautic vehicles, transportation and packaging, etc., can solve the problems of increasing the weight of the cmg, reducing the efficiency of the rotor-to-spacecraft load path, and reducing the efficiency of the gyroscop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The following Detailed Description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding Background or the following Detailed Description.

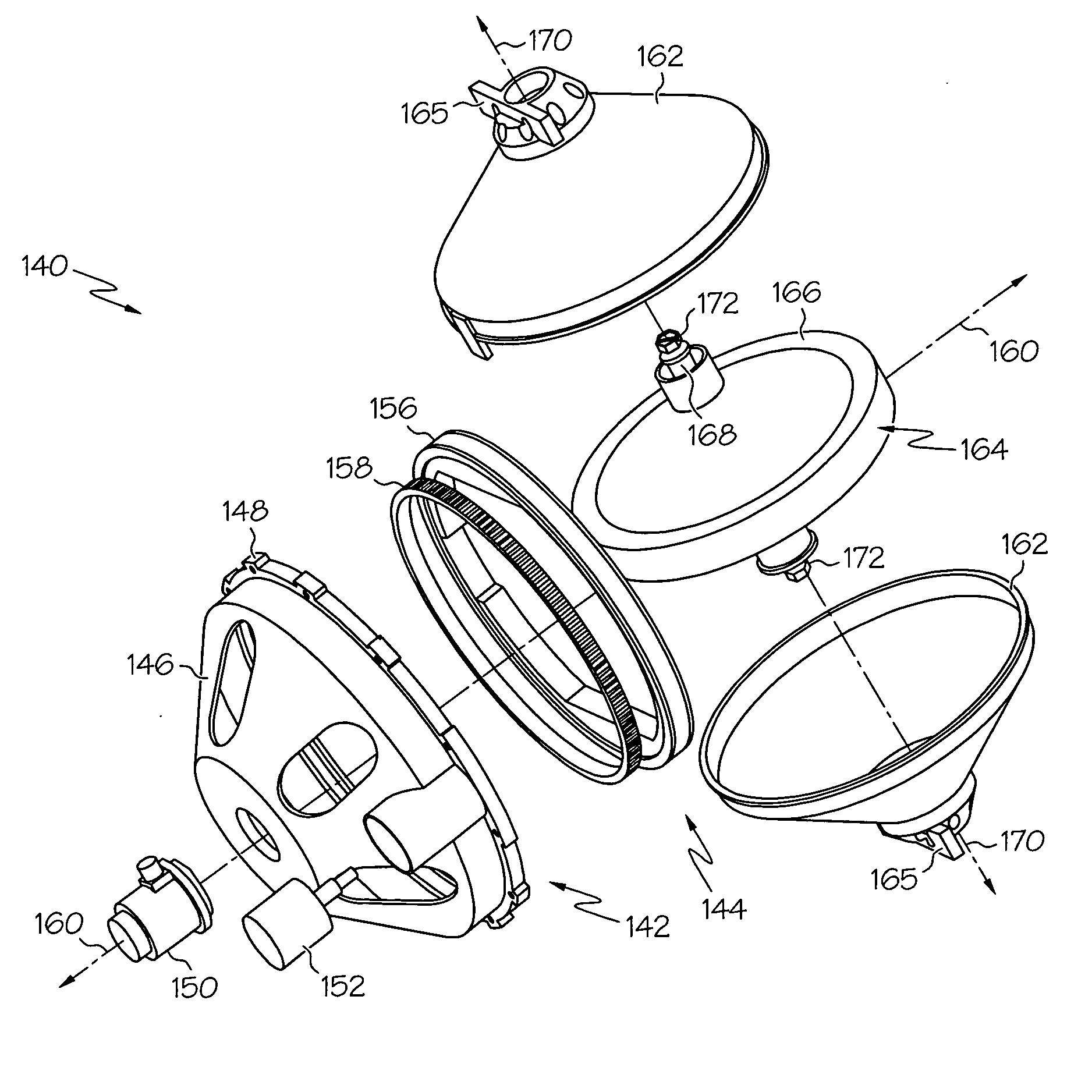

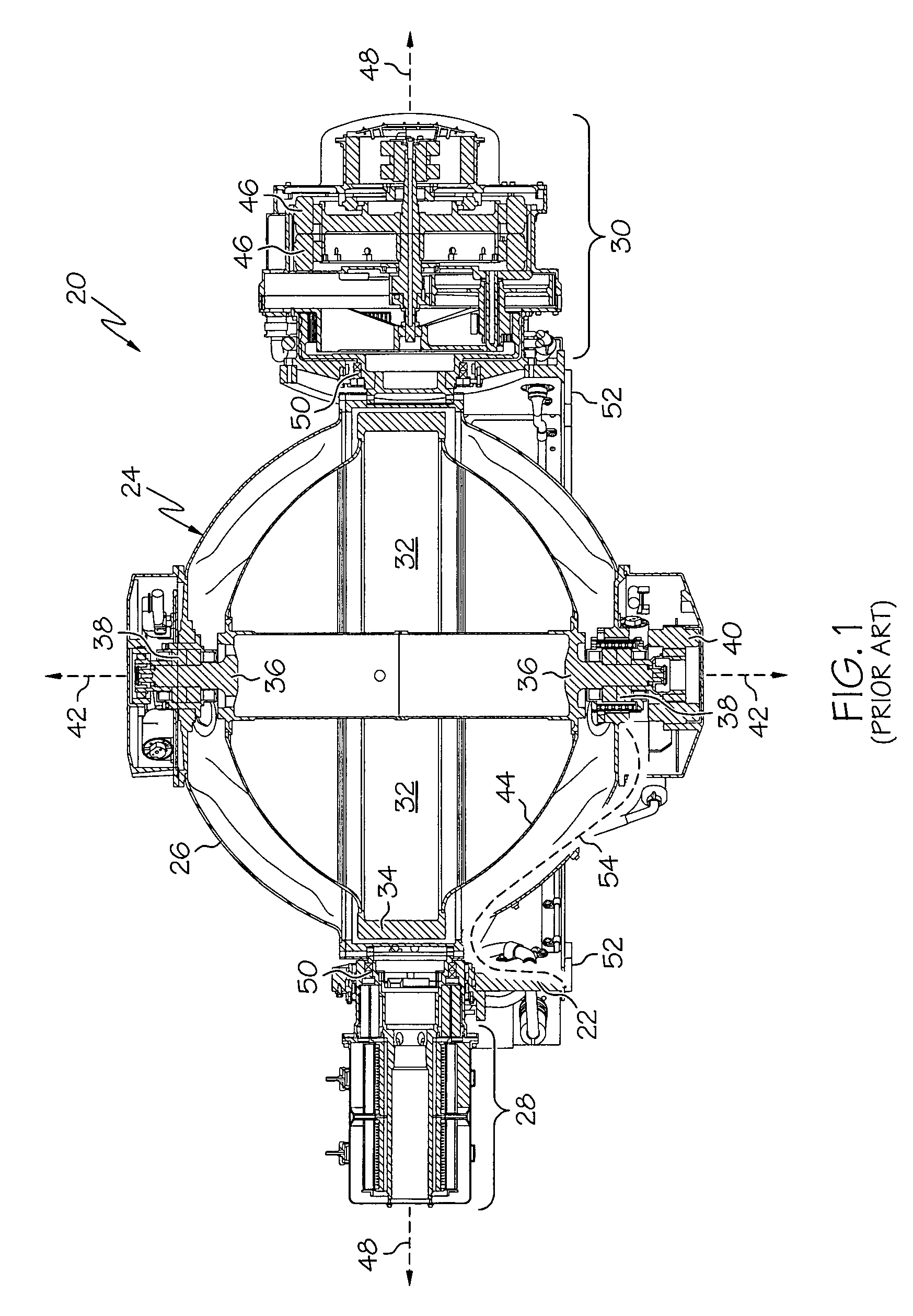

[0014]In the subsequent description, reference is made to an exemplary signal module assembly (SMA) and to an exemplary torque module assembly (TMA). It is noted that the signal module assembly may also be referred to as a “sensor” module assembly, and that the torque module assembly may also be referred to as a torque “motor” assembly. Regardless of the particular terminology used, the signal module assembly may comprise any body or device suitable for transmitting electrical signals and / or power across a rotary interface (e.g., a slip ring assembly). Similarly, the torque module assembly or torque motor assembly may comprise any device or system suitable for imparting torque to a rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com