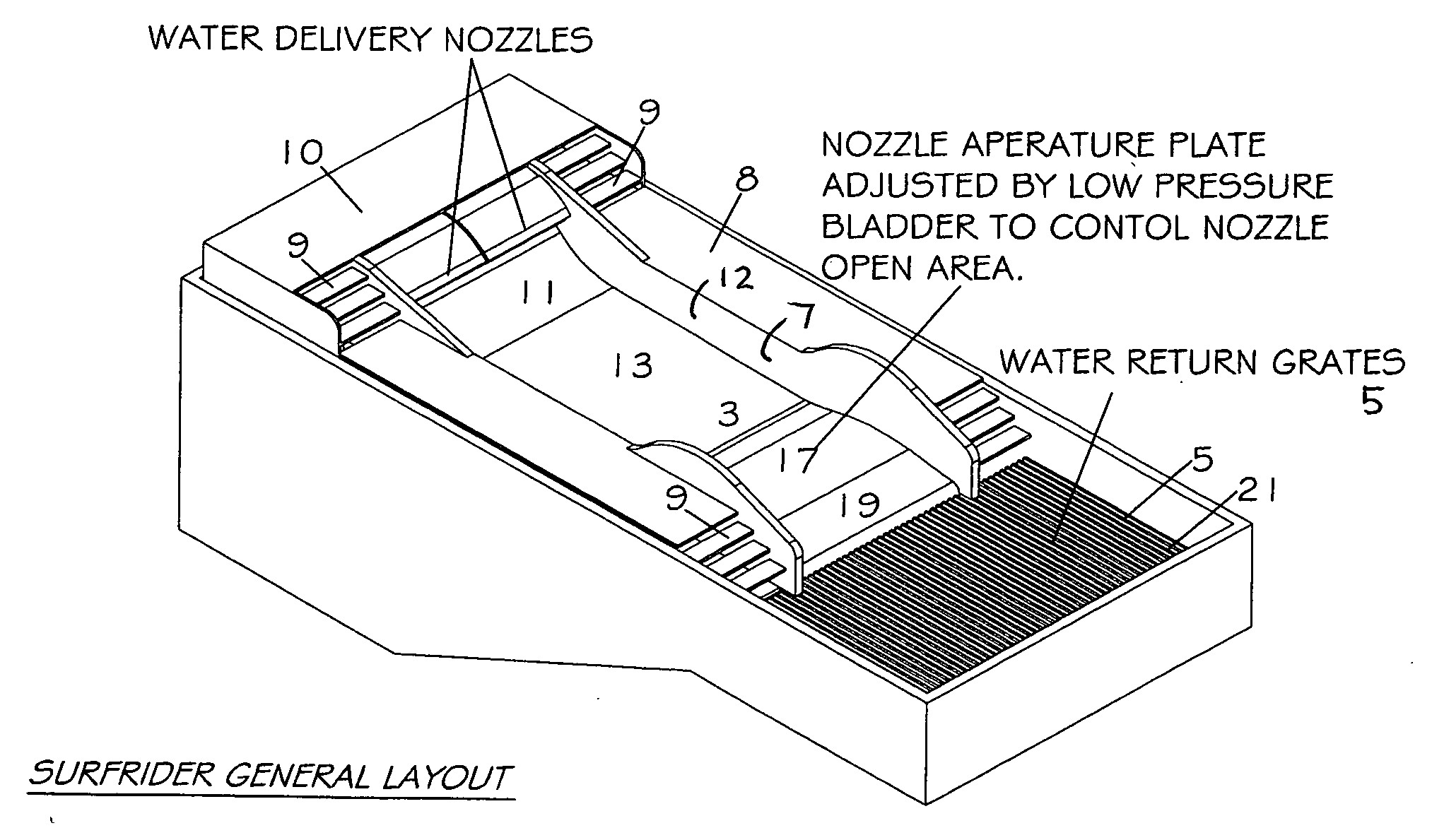

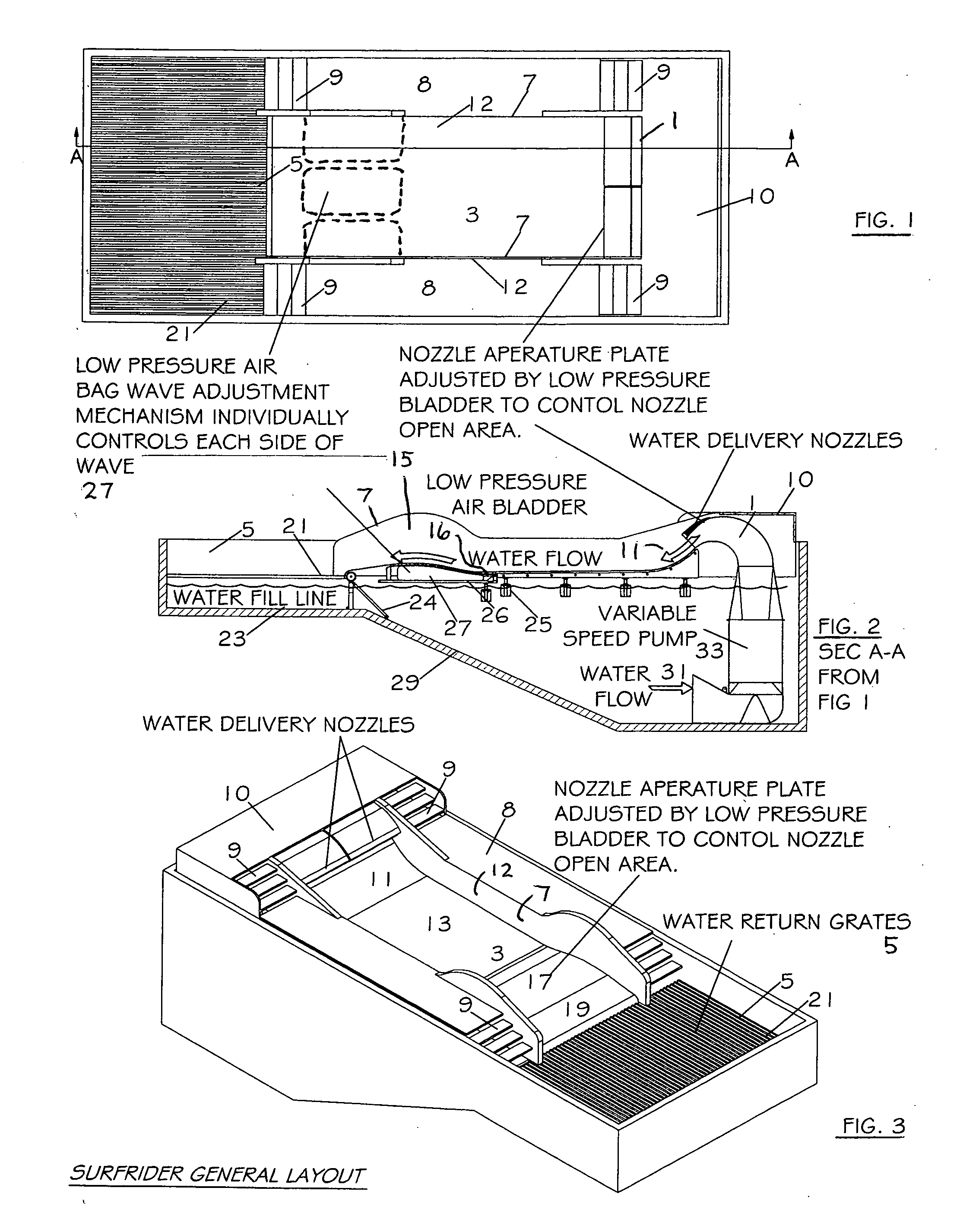

[0014]The present invention relates to a water ride having an adjustability feature that enables the depth of the flowing body of water being propelled onto an inclined or contoured ride surface to be easily adjusted. The adjustability feature is preferably used in conjunction with the sheet flow water ride technology previously developed by Applicant which has been described above, as well as a relatively deep sheet flow variation of it (which will collectively be referred to as a “sheet flow water ride” for simplicity purposes), which includes an inclined or contoured ride surface upon which the sheet flow of water is propelled. The present adjustability feature preferably enables the depth of the sheet flow to be adjusted, such that by itself, or in conjunction with other adjustability features, including the adjustment of the flow speed, or incline and / or tilt of the ride surface, a variety of dynamic changes to the nature and character of the sheet flow can be created, thereby giving riders a chance to experience a wide range of flow conditions, including relatively shallow and deep flows on the same ride surface.

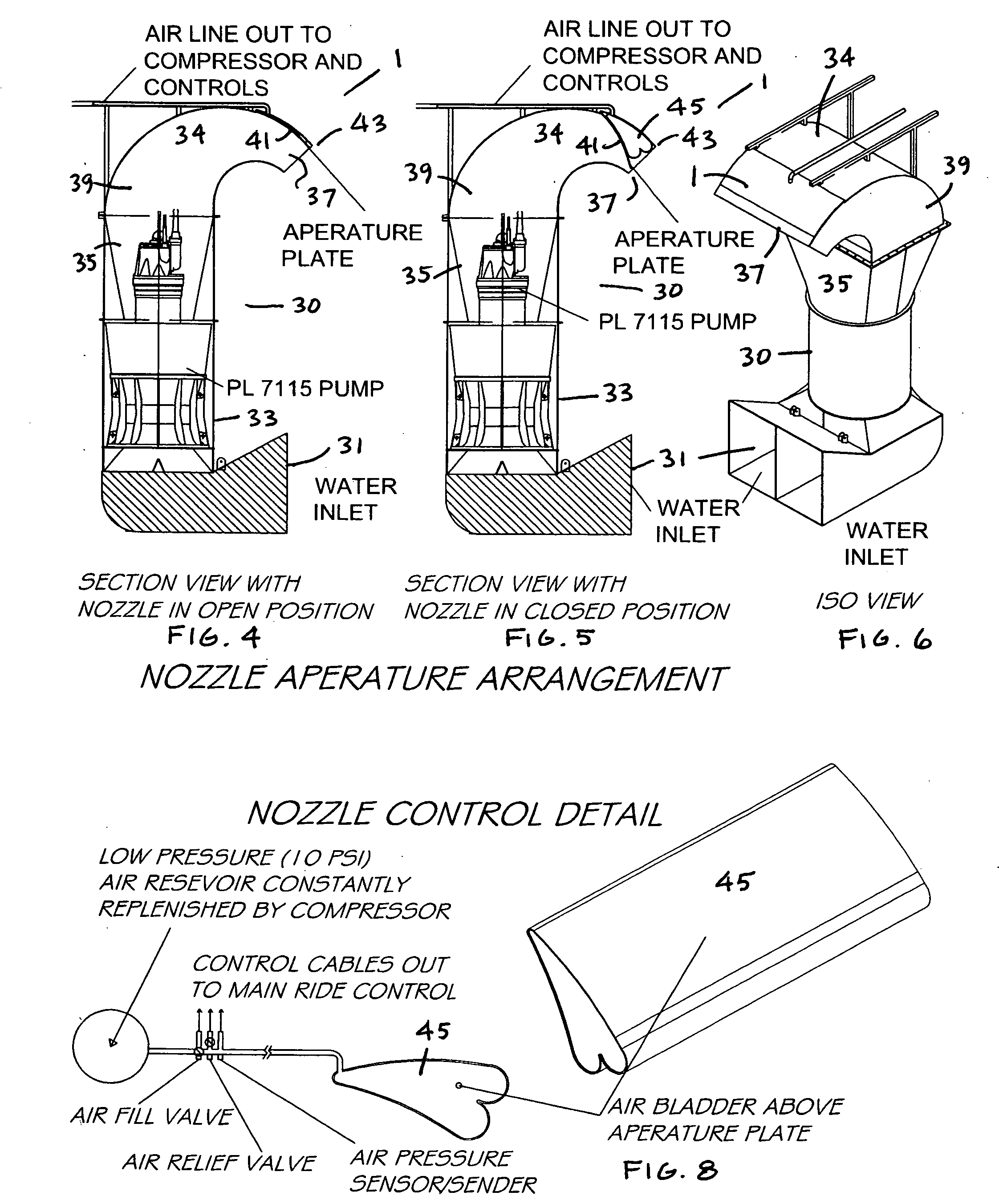

[0015]Generally speaking, the present invention comprises nozzles with an adjustable aperture capable of releasing a sheet flow of water under

high pressure onto the associated ride surface at varying depths. The

nozzle component preferably comprises a pump with an inlet capable of drawing water in from a source, wherein the water is placed under

high pressure and allowed to be channeled through a narrowing nozzle aperture, and then released. The aperture is configured so that water is extruded through the nozzle and forms a focused-propulsion of water that rapidly disperses onto the ride surface, and forms a continuous sheet flow of water thereon, wherein by adjusting the

effective height of the aperture, the depth of flow can be adjusted.

[0019]These adjustments can facilitate adjustments in the nature and character of the sheet flow of water propelled onto the ride surface. For example, by decreasing the depth of flow, a relatively

thin sheet flow of water, traveling at an increased velocity, similar to those contemplated by the previous invention, can be created on the ride surface. On the other hand, by increasing the depth of flow, a relatively deep sheet flow of water can be created on the same ride surface, which can enable riders to use standard surfboards with fins. Likewise, by having two or more adjustable nozzles side by side, a portion of the flow can be made to enter the ride surface at one depth, and another portion of the flow can be made to enter the ride surface at another depth, which can create varied flow effects, including a hydraulic jump on one side, and

supercritical flow on the other, even across a level

ridge line.

[0020]Although these variations can be made without having to make any other adjustments, the present invention contemplates that these adjustments can be combined with other adjustments, such as to the flow speed, or inclination or tilt of the ride surface, wherein the adjustability and variability of the flow can be increased and enhanced, and an increased variety of dynamic flow changes and hydraulic states can be produced, which can further enhance and add variety to the rider's experience. For example, in addition to creating two hydraulic states across the ride surface based on flow depth variations, the speed with which the flow enters onto the ride surface within these hydraulic states can also be varied. Moreover, the inclination of the ride surface upon which these hydraulic states are created can be increased, decreased, or even tilted, thereby further varying the flow effects. This way, the degree to which these hydraulic states can form, dissipate, change in shape, change in size, and move around on the ride surface, etc., can be easily modified and varied.

[0021]Another related

advantage is the ability of these adjustments to solve the transient surge problems associated with ride start-up and rider induced flow decay upon upwardly inclined flow surfaces. Because the flow depth can be controlled precisely, and because whether a particular flow remains supercritical is a function of flow depth, these adjustments preferably provide a means for self-clearing undesirable transitory surges and excess

white water, which can help correct the problems associated with start-up and flow decay.

Login to View More

Login to View More  Login to View More

Login to View More