Shell stripper assembly

a shell and assembly technology, applied in the field of shell stripper assembly, can solve the problems of imposing undesirable dimensional constraints in the design of the firearm, the reliability of this action may suffer, and achieve the effect of efficient and reliable magazine engagement, easy and reliable engagement, and minimizing or eliminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The shell stripper assembly according to the present embodiments generally relates to a feeding mechanism for stripping and / or feeding the top round of ammunition being fed from a magazine into the chamber of a firearm, such as a rifle, shotgun or other long gun, or a handgun. The firearm further can be, for example, a gas actuated, inertia actuated, semiautomatic, pump action, bolt action, or other type of firearm.

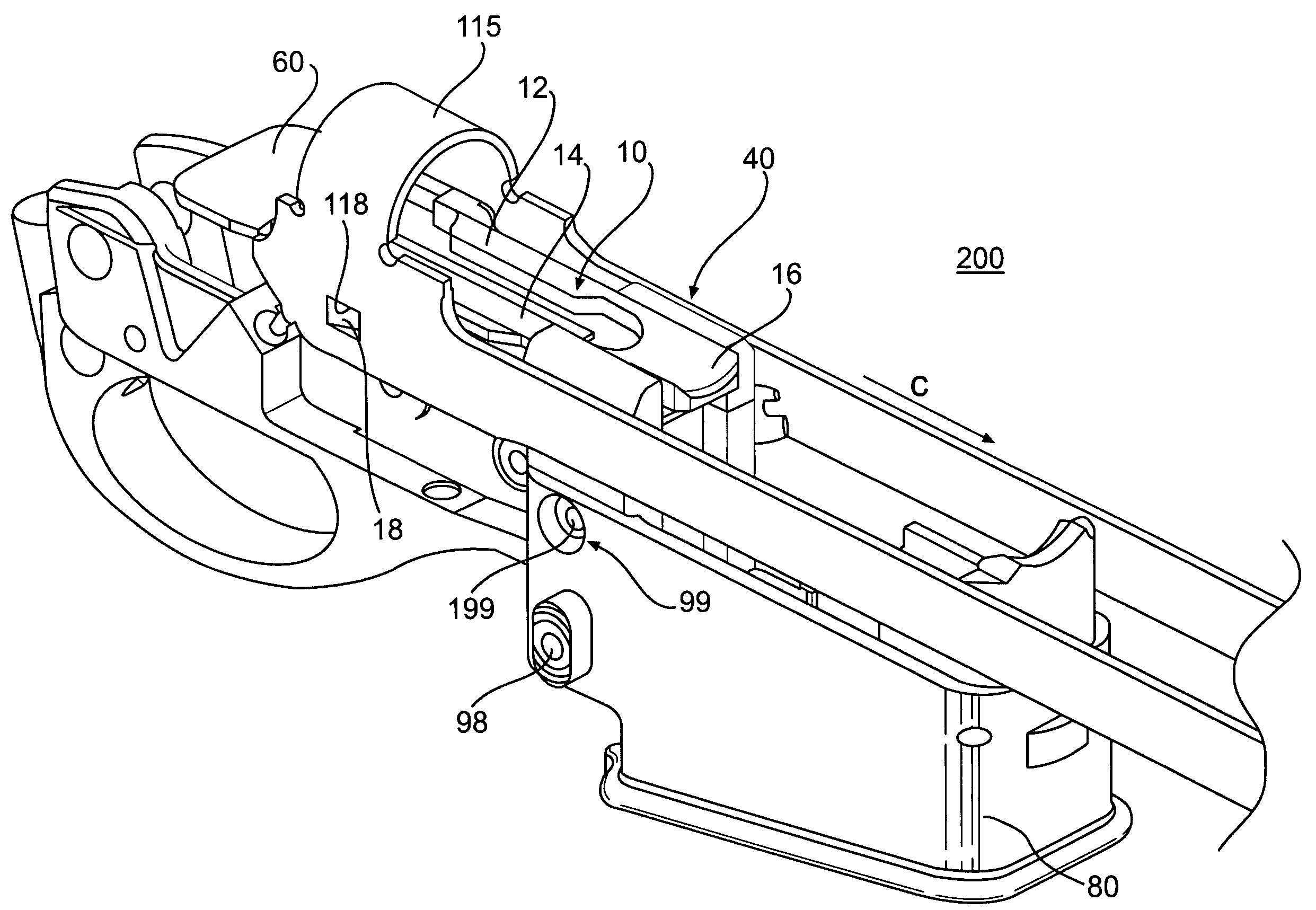

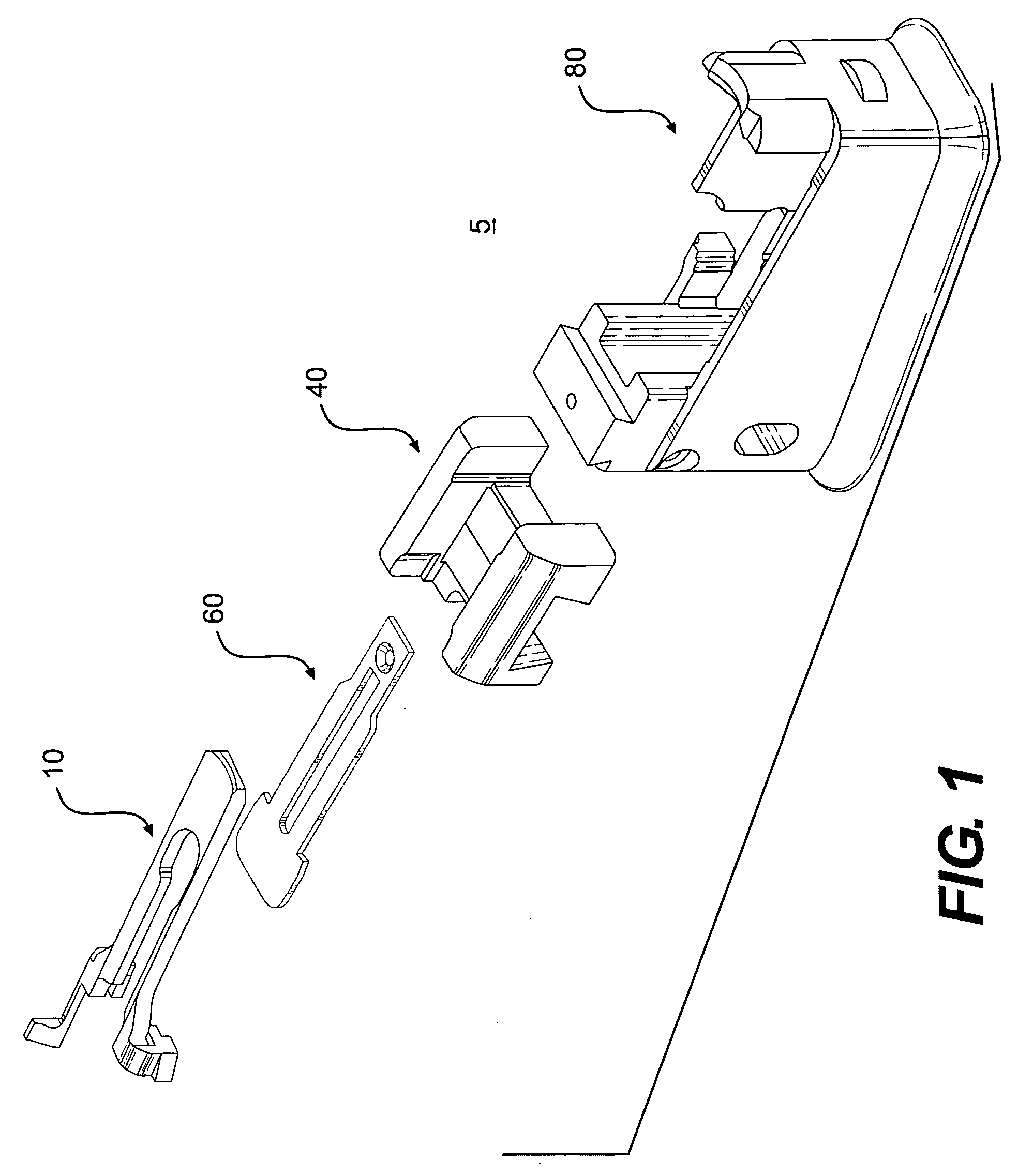

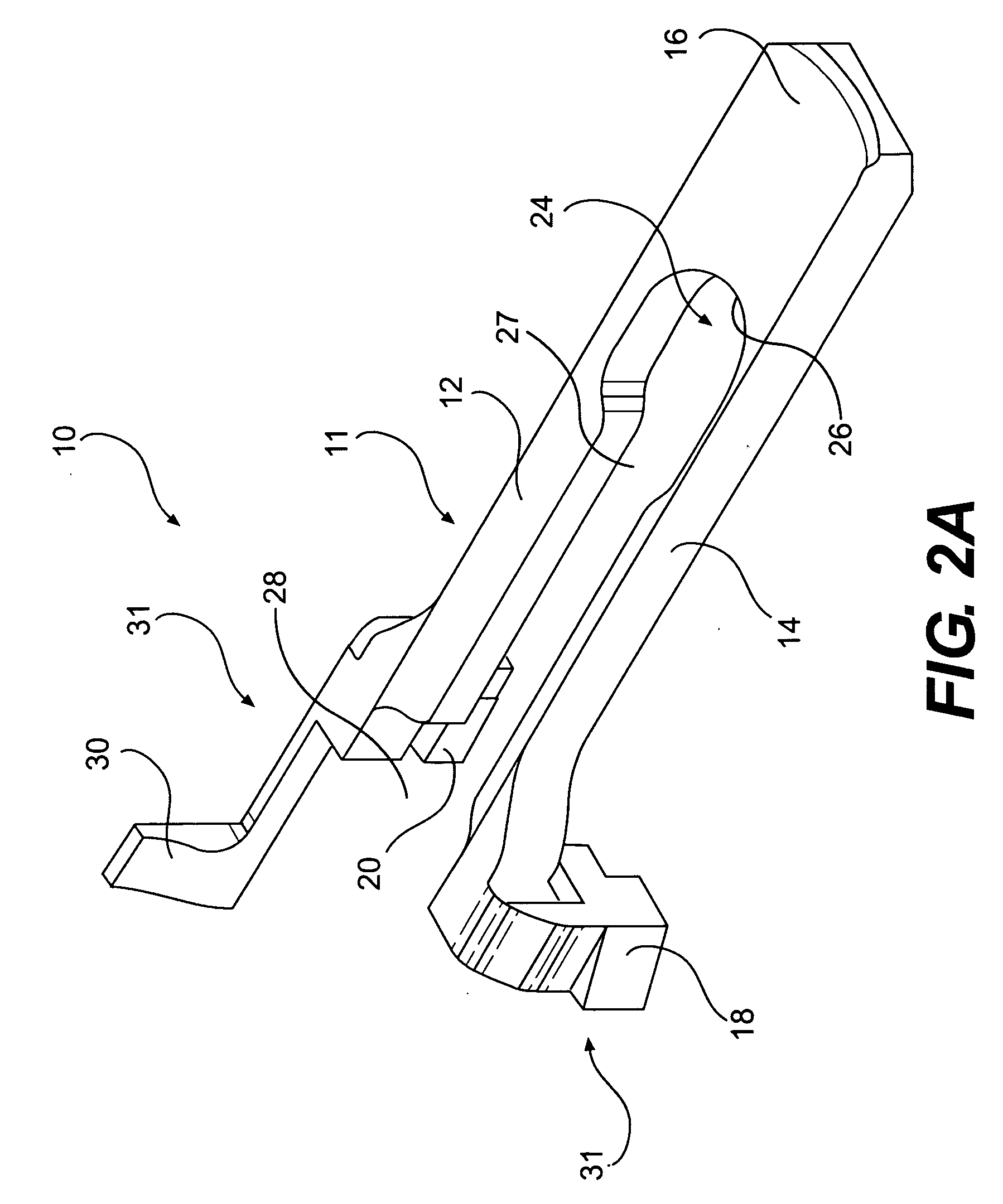

[0032]Referring now to the drawings in which like numerals indicate like parts throughout the several views, FIG. 1 is an exploded perspective view of the individual components of a first example embodiment of a shell stripper assembly 5 according to the principles of the present invention. The shell stripper assembly 5 includes a shell stripper 10, a stripper guide 40, a stripper guide plate 60 and a magazine insert 80. Each of the components of the shell stripper assembly 5 are discussed in further detail below, followed by a discussion of their functions within a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com