Shirt Collar Size Adjusting Frame

a collar and size technology, applied in the field of shirt collar size adjustment frame, can solve the problems of increasing the size of the shoulders or chest of the shirt, affecting the comfort of wearing, and affecting the comfort of wearing, and achieve the effect of enhancing the convenience of wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

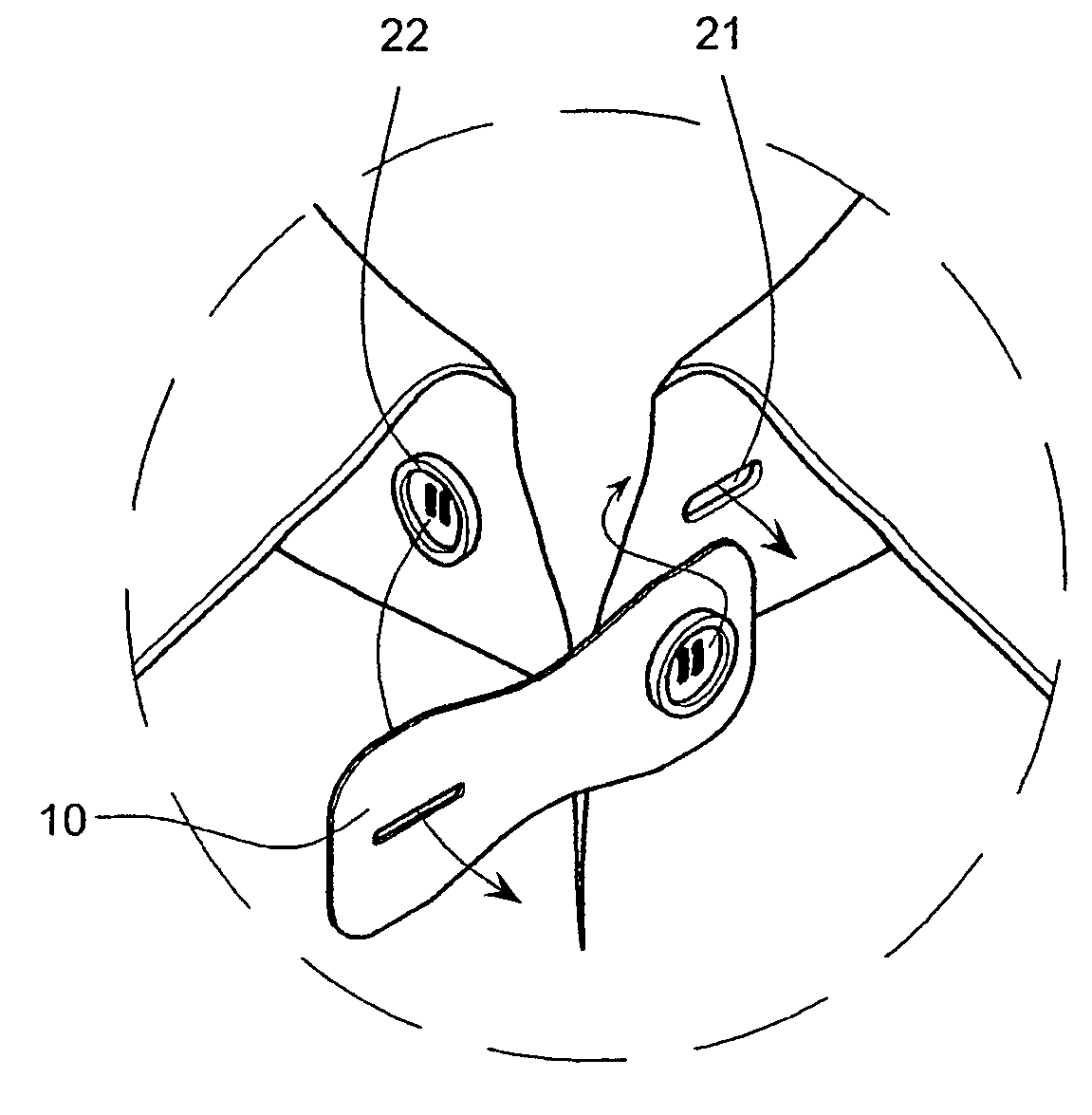

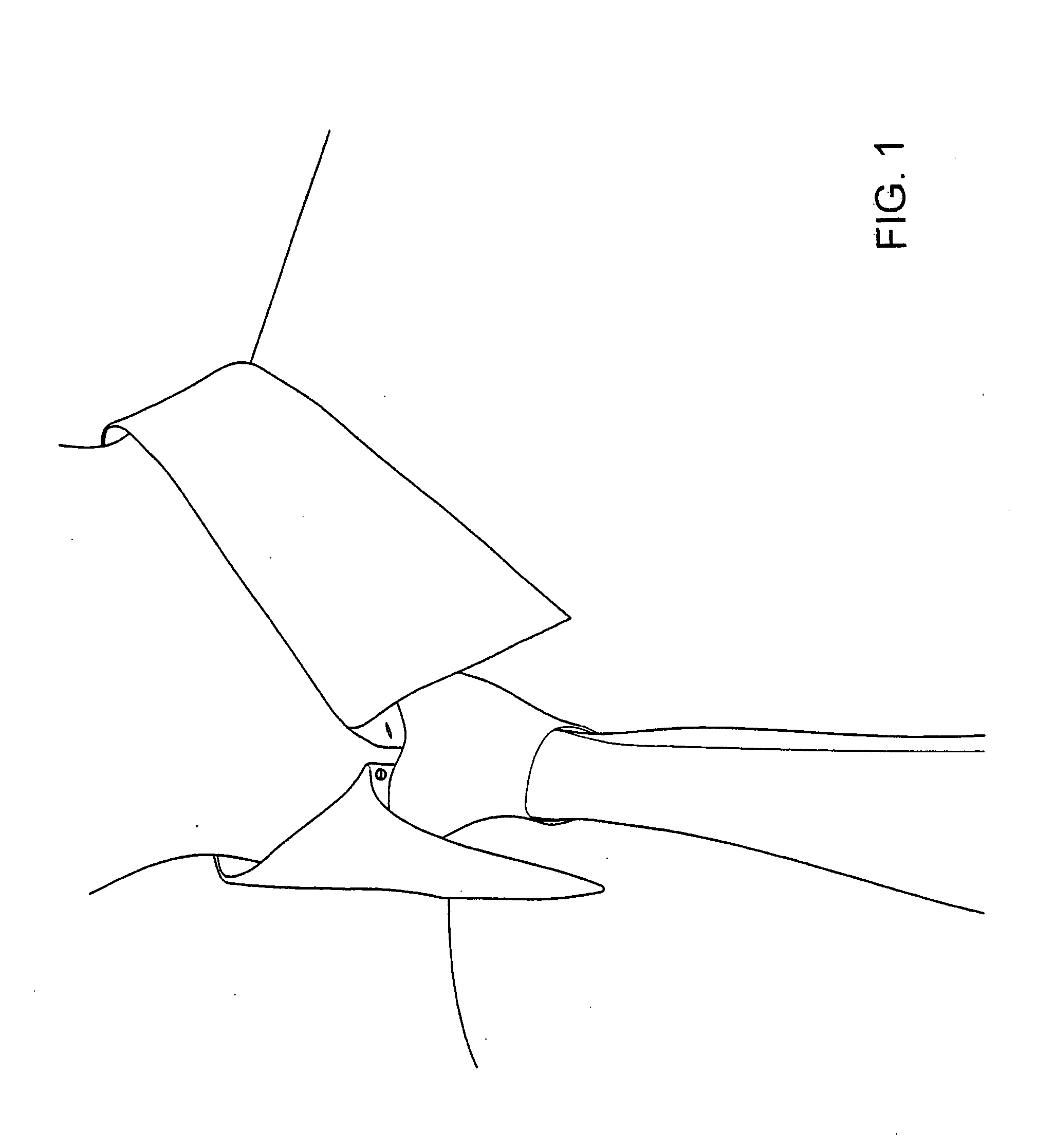

[0020]Referring first to FIG. 2 showing a shirt collar size adjusting frame 10 according to the present invention, the shirt collar size adjusting frame 10 that is made by folding a piece of fabric has a fastening button 11 provided at one side thereof and a slit 12 formed at the other side thereof, the slit 12 being formed of a horizontally elongated hole.

[0021]Under the above structure, the shirt collar size adjusting frame 10 according to the first embodiment of the present invention is adapted to connect the opposite ends of the collar when the shirt is worn, thereby preventing the opposite ends of the collar from being opened, even when a collar button 22 is not inserted through a button hole 21 formed on the collar.

[0022]As shown in FIGS. 3 and 4, that is, the shirt collar size adjusting frame 10 according to the first embodiment of the present invention is used wherein the collar button 22 is inserted through the slit 12 and the fastening button 11 is inserted through the but...

second embodiment

[0024]On the other hand, FIGS. 5a and 5b are views showing a shirt collar size adjusting frame 10 according to the present invention, wherein the shirt collar size adjusting frame 10 is formed of a hard material like acryl or transparent plastic and the slit 12 is formed of an elongated hole having a predetermined length in a horizontal direction, the slit having a plurality of vertically cut portions 12a formed at given intervals in such a manner as to be extended downwardly therefrom such that the fastening positions of the collar button 22 are varied, if necessary.

[0025]That is, in the state where the collar button 22 formed on the shirt collar is inserted through the slit 12 formed on the shirt collar size adjusting frame 10 and the fastening button 11 is inserted through the button hole 21 formed on the shirt collar, if the collar button 22 is placed at an appropriate position on the slit 12, the shirt collar size adjusting frame 10 is raised upwardly, such that the collar butt...

third embodiment

[0027]Further, FIGS. 6a and 6b are views showing a shirt collar size adjusting frame according to the present invention, wherein the slit 12 is formed of an elongated hole having a predetermined length in a horizontal direction, the slit having a plurality of circular guide grooves 12b formed at given intervals therealong such that the fastening positions of the collar button 22 are varied.

[0028]So as to increase the frictional force of the slit 12 against the collar button 22 to provide a force of maintaining its fixed position thereto, the slit 12 desirably has a friction layer 13 formed therearound, the friction layer 13 being formed of a thin urethane or rubber film.

[0029]Under the structure of the shirt collar size adjusting frame according to the third embodiment of the present invention, in the state where the collar button 22 formed on the shirt collar is inserted through the slit 12 formed on the shirt collar size adjusting frame 10 and the fastening button 11 is inserted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com