Cooling fan

a cooling fan and fan body technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of many noise problems, and achieve the effect of changing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

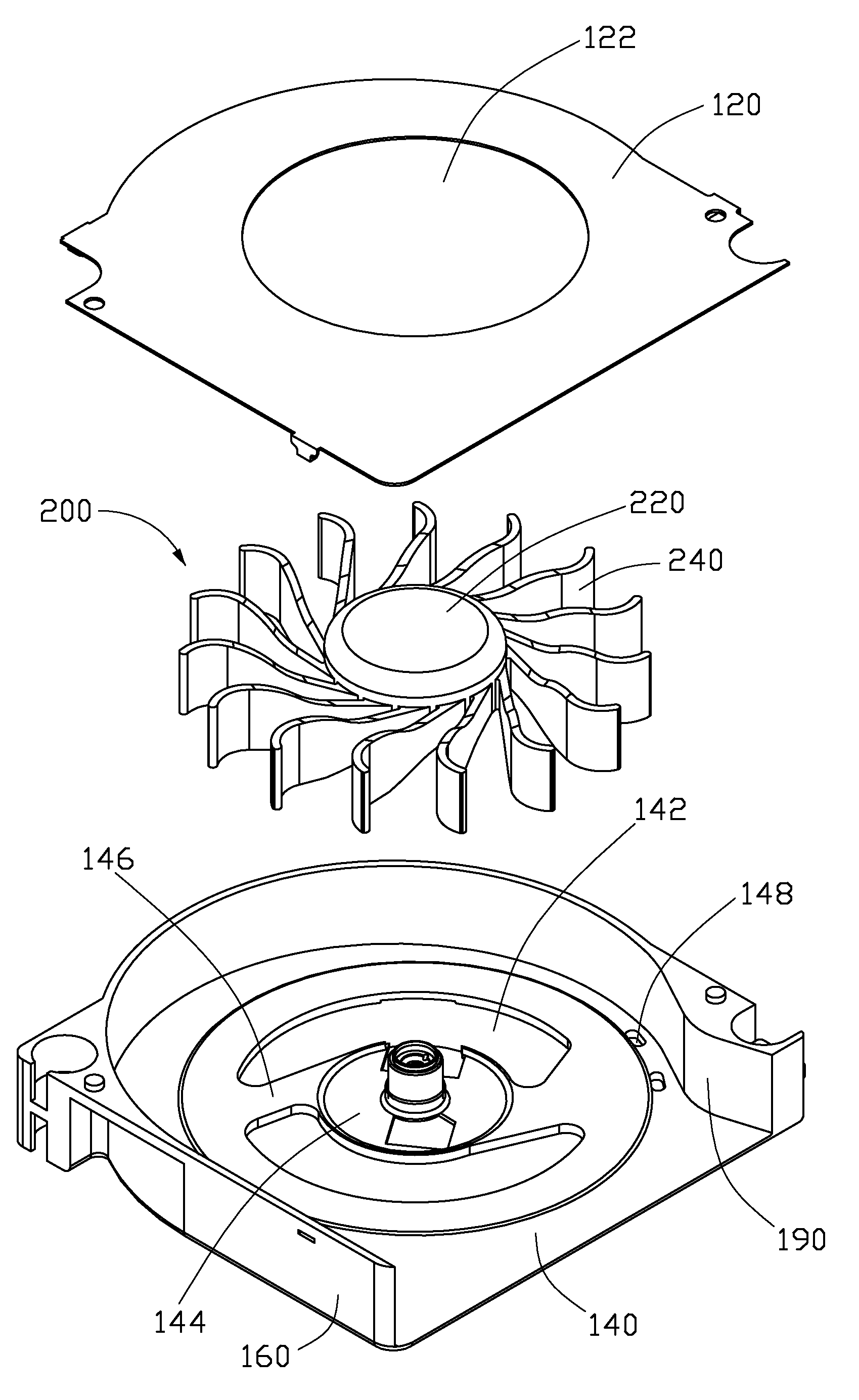

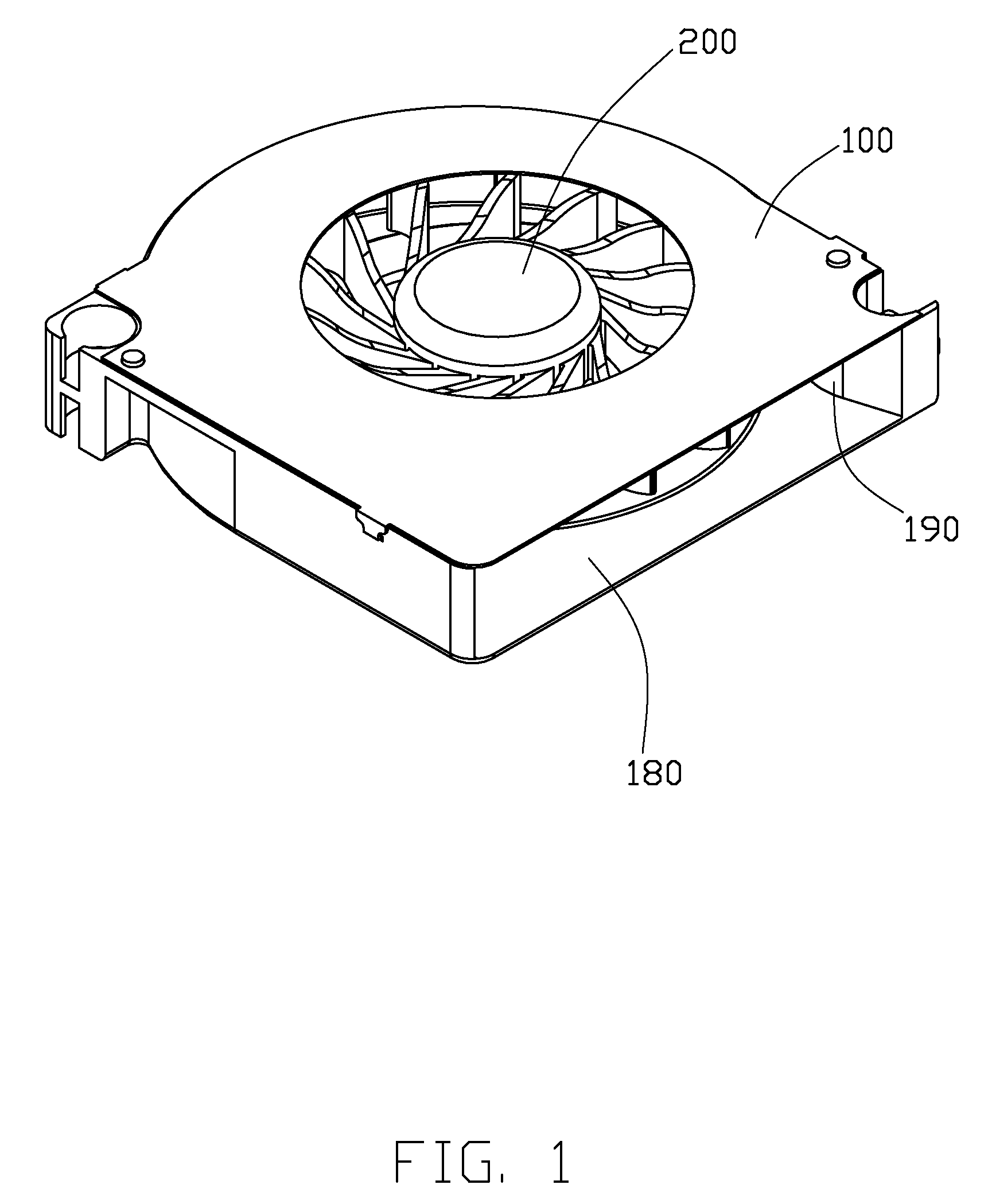

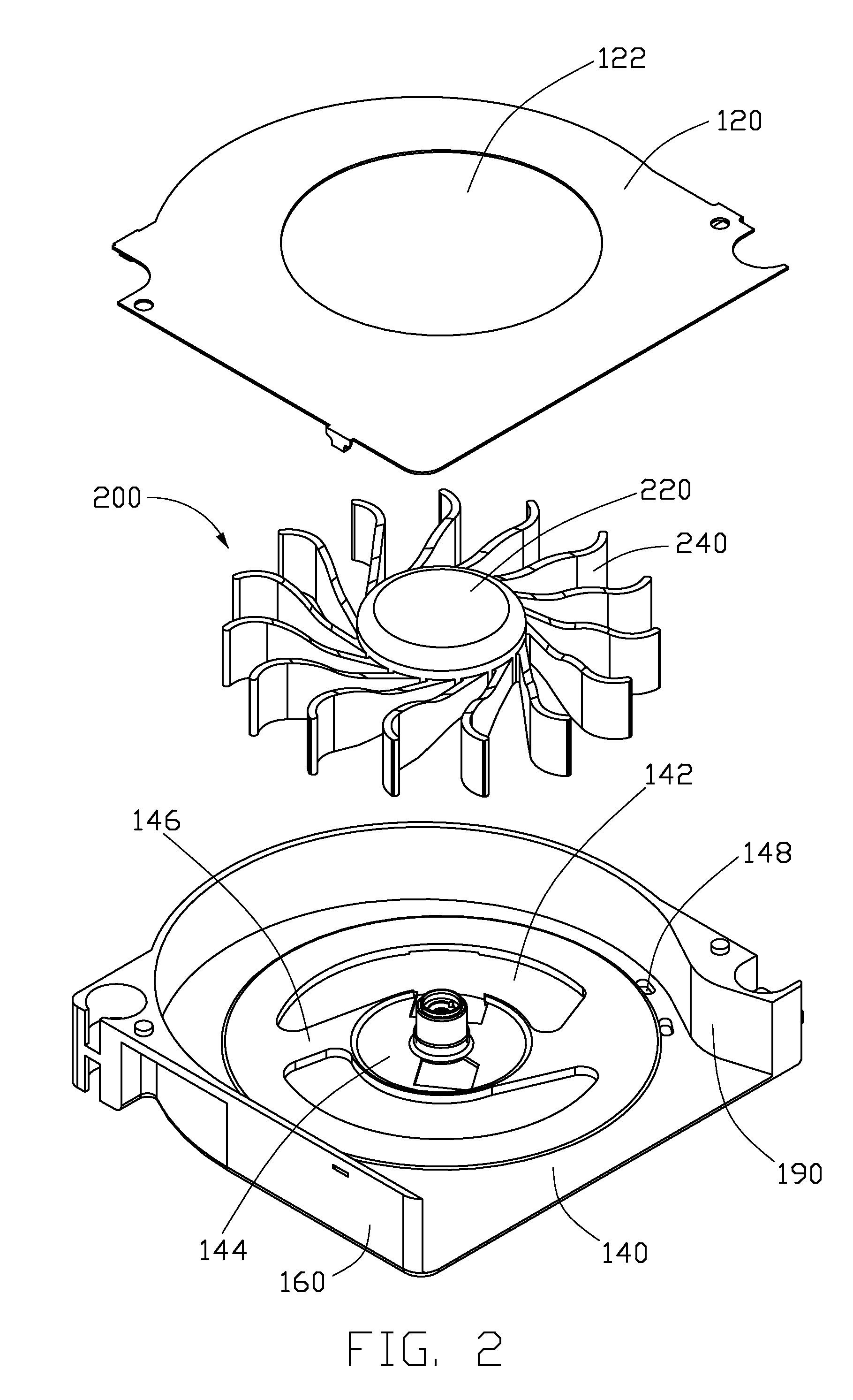

[0013]Referring to FIGS. 1-2, a cooling fan of a preferred embodiment of the invention comprises a frame 100, and an impeller 200 disposed in the frame 100. The impeller 200 comprises a hub 220 and a plurality of blades 240 mounted on the hub 220.

[0014]The frame 100 comprises a cap 120, a base 140, and a sidewall 160 perpendicularly and upwardly extending from a periphery of the base 140. The cap 120 is mounted on the sidewall 160 with a chamber formed between the cap 120, the base 140 and the sidewall 160. The impeller 200 is disposed in the chamber to blow an outward airflow out of the chamber from an air outlet 180, which is defined in a front of the sidewall 160. A curved tongue portion 190 protrudes inwardly from the sidewall 160, and is adjacent to the air outlet 180 to adjust airflow flowing into the frame 100.

[0015]The cap 120 and the base 140 respectively define a first air inlet 122 and a second air inlet 142 therein. The air enters into the chamber via the first and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com