Robot cleaner system having robot cleaner and docking station

a robot cleaner and robot technology, applied in the direction of suction cleaners, cleaning filter means, suction filters, etc., can solve the problems of dust leakage, large loss of suction force generated by the suction unit, and complicating the configuration of the dust-removal device, so as to prevent dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Reference will now be made in detail to exemplary embodiments, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. Exemplary embodiments are described below by referring to the figures.

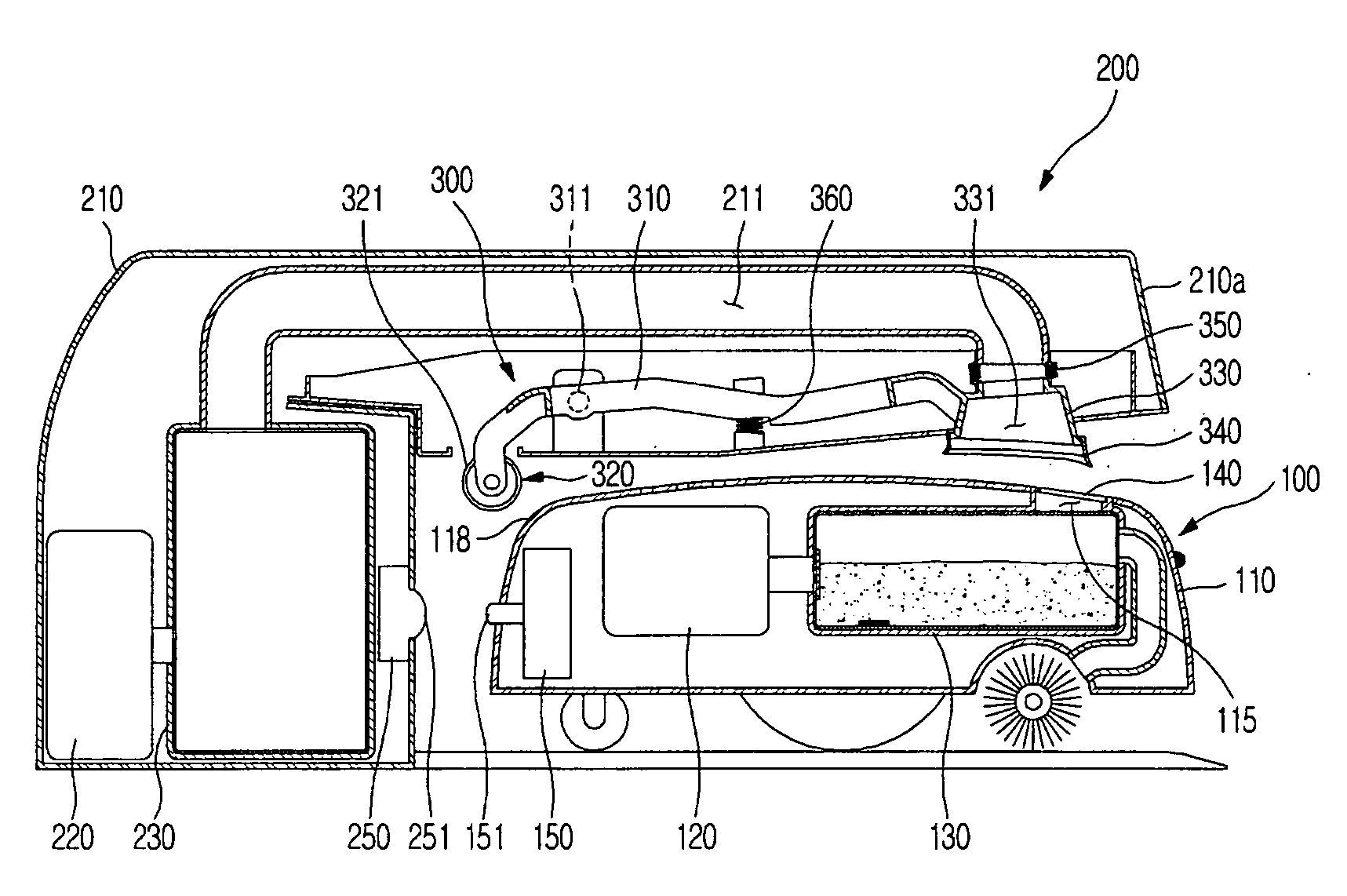

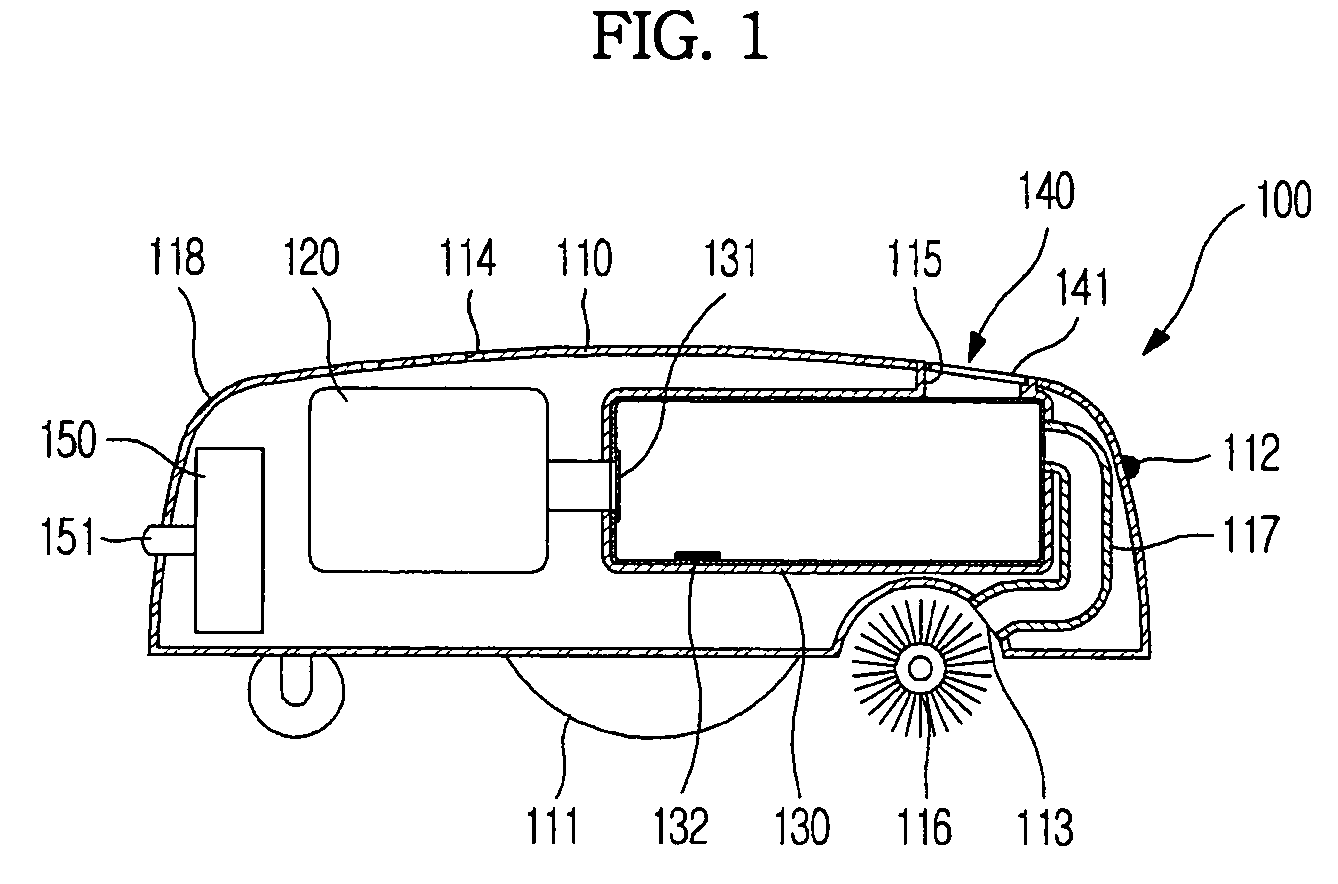

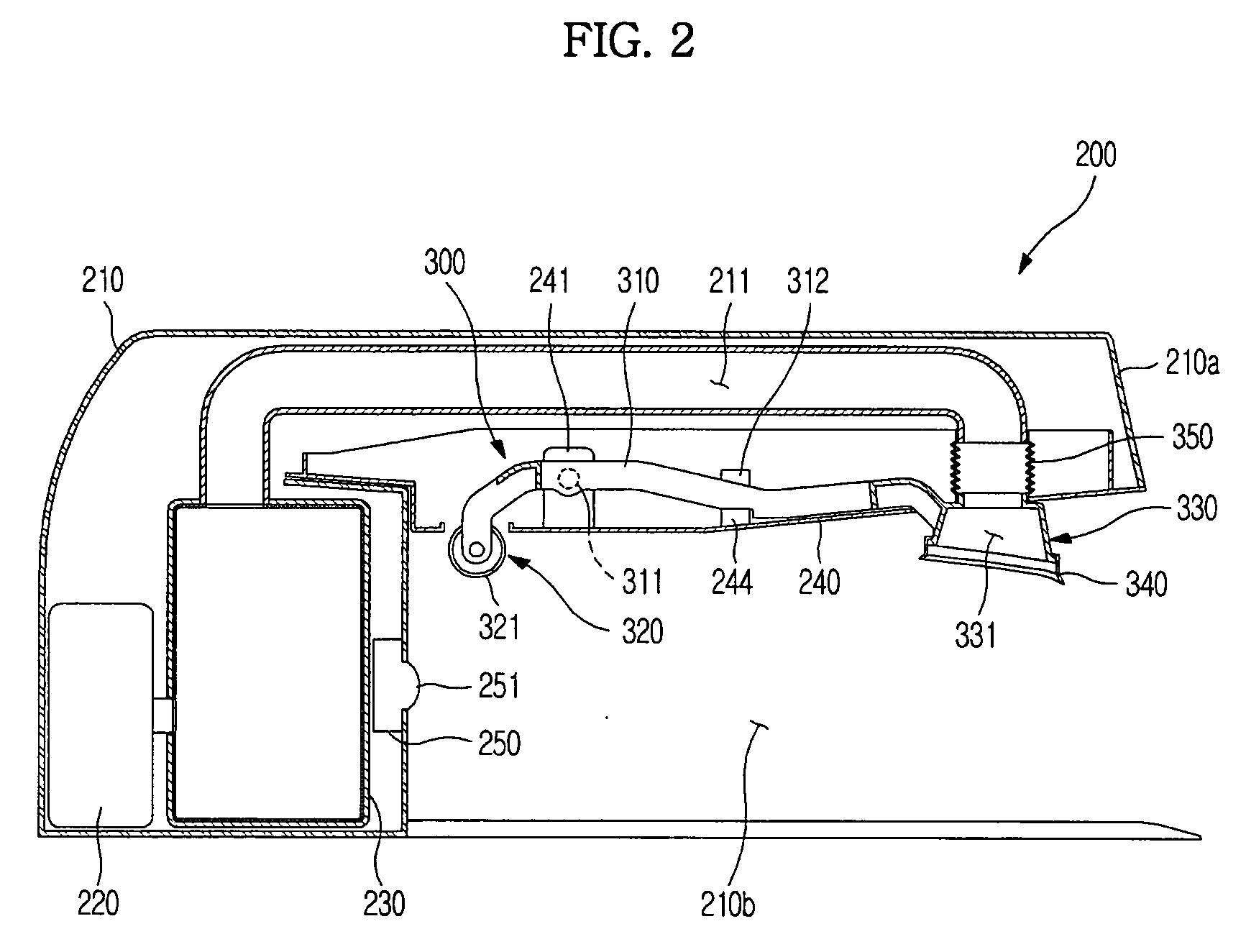

[0042]FIGS. 1 and 2 are sectional views, respectively, showing a robot cleaner and a docking station of a robot cleaner system according to an exemplary embodiment.

[0043]As shown in FIGS. 1 and 2, the robot cleaner system according to an exemplary embodiment includes a robot cleaner 100 and a docking station 200. The robot cleaner 100 performs a cleaning operation for a cleaning region by self-running thereof, and returns to the docking station 200 if dust over a predetermined level is accumulated therein, to discharge the dust.

[0044]As shown in FIG. 1, the robot cleaner 100 includes a robot body 110, and a first suction device 120 and a first dust-collecting device 130 installed in the robot body 110.

[0045]The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com