Metallurgical Gas Burner

a gas burner and metallurgical technology, applied in the direction of gaseous fuel burners, combustion types, combustion processes, etc., can solve the problems of increased loading, vibration in the combustion chamber, damage to the lining of steel structures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

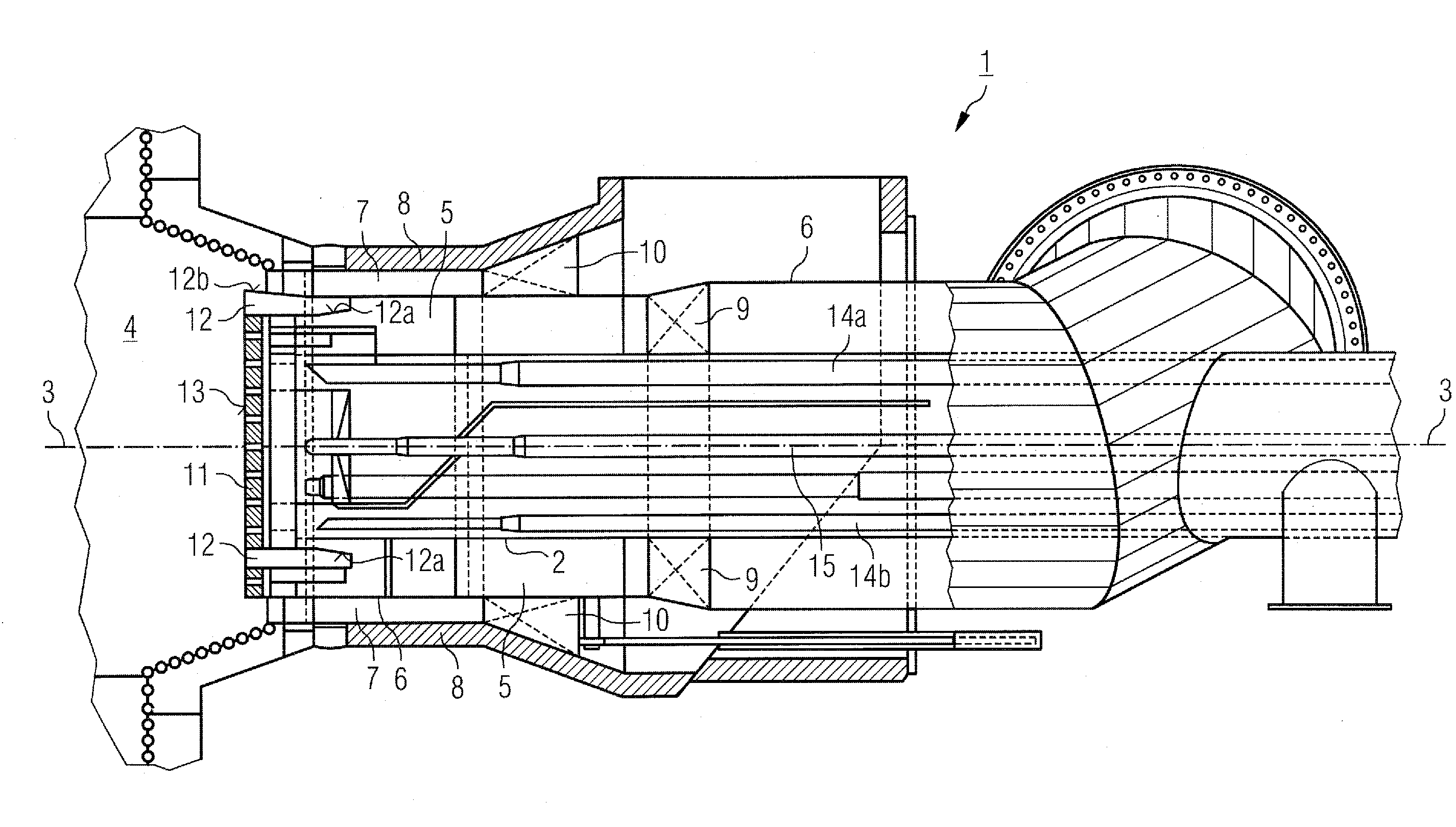

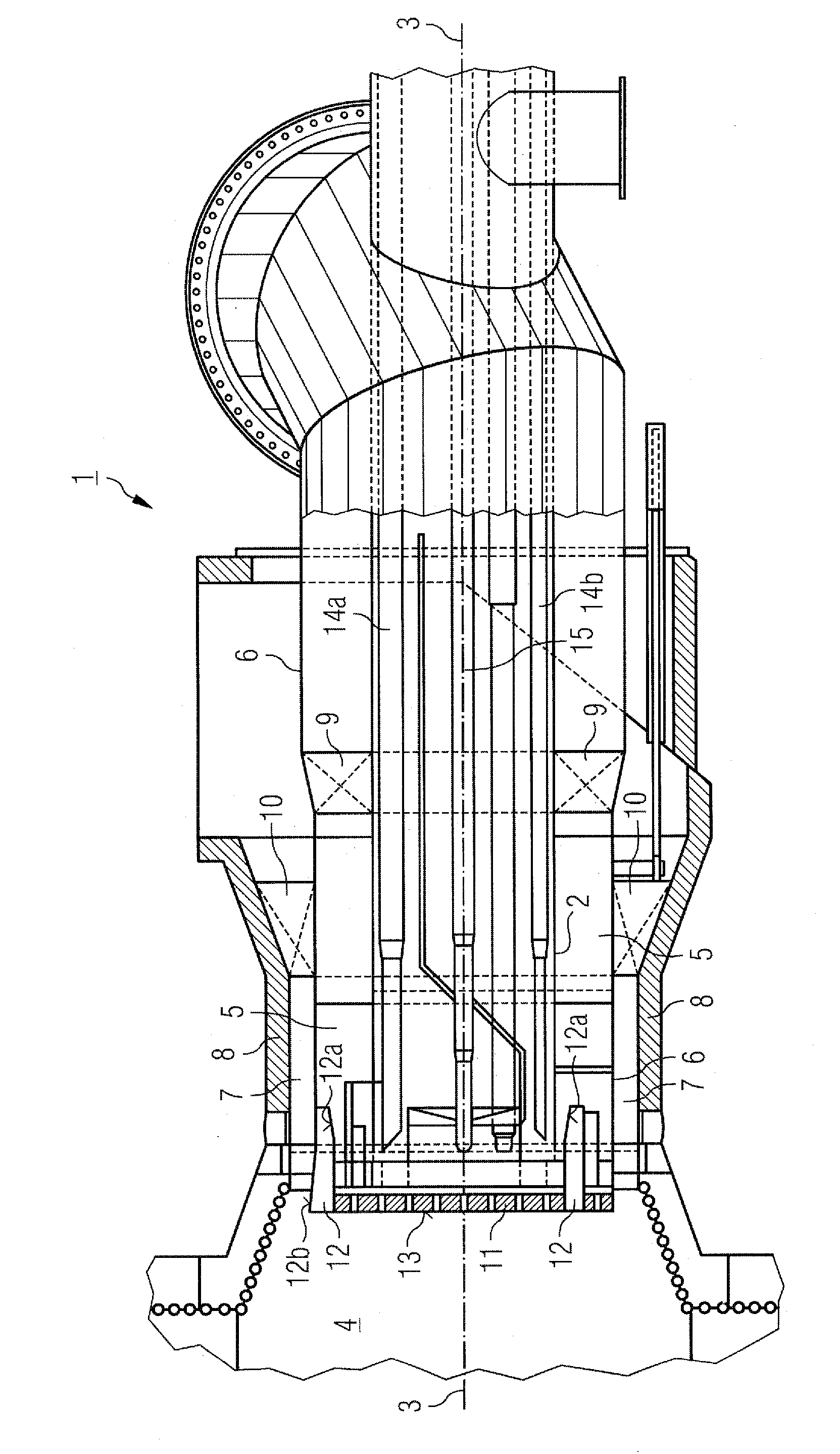

[0019]FIGURE shows in a schematic and partially sectional side view and cross-sectional representation a steam generator gas burner denoted overall by 1, which is designed in the form of what is known as an annular burner. The burner has a core air tube 2, which is arranged in the centre of the steam generator gas burner 1, coaxially around the longitudinal axis 3 of the latter. Combustion air is supplied as core air through the core air tube 2 to the mouth side of the steam generator gas burner 1 that is facing a furnace chamber 4 of a steam generator. Formed around the outside of the core air tube 2, at least in the further end region of the steam generator gas burner 1 on the mouth side, is an annular gas flow cross section 5. This gas flow cross section 5 is delimited on the outside by a gas tube 6, which is arranged coaxially around the core air tube 2. Formed around the gas tube 6 is a further flow region as an annular secondary air flow cross section 7, which is enclosed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com