Prefabricated wall panels and a method for manufacturing the same

a technology manufacturing methods, which is applied in the field of modular construction, can solve the problems of slowing down manufacturing, affecting the quality of prefabricated wall panels, and limiting the size of available building panels, and achieves the effect of convenient customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

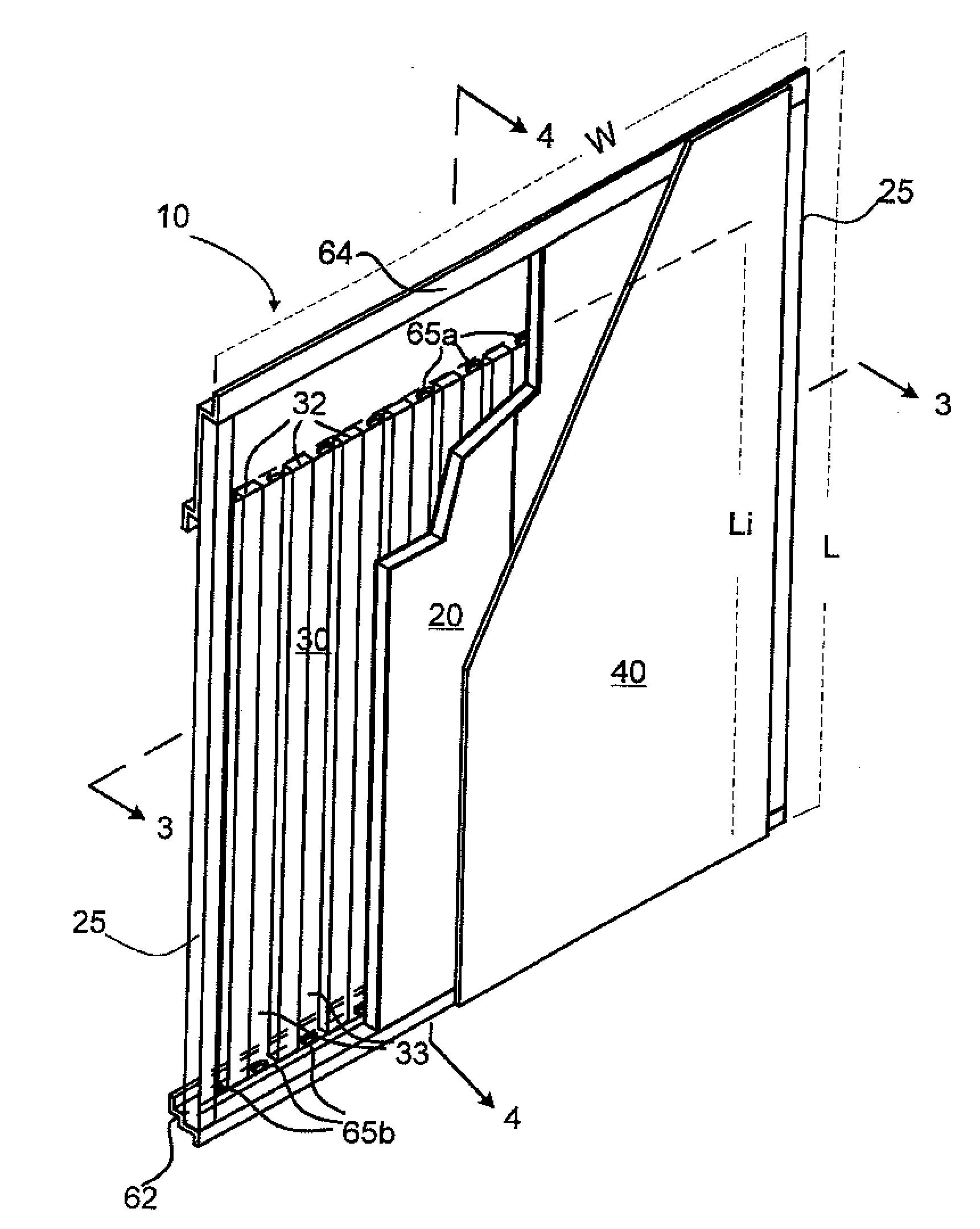

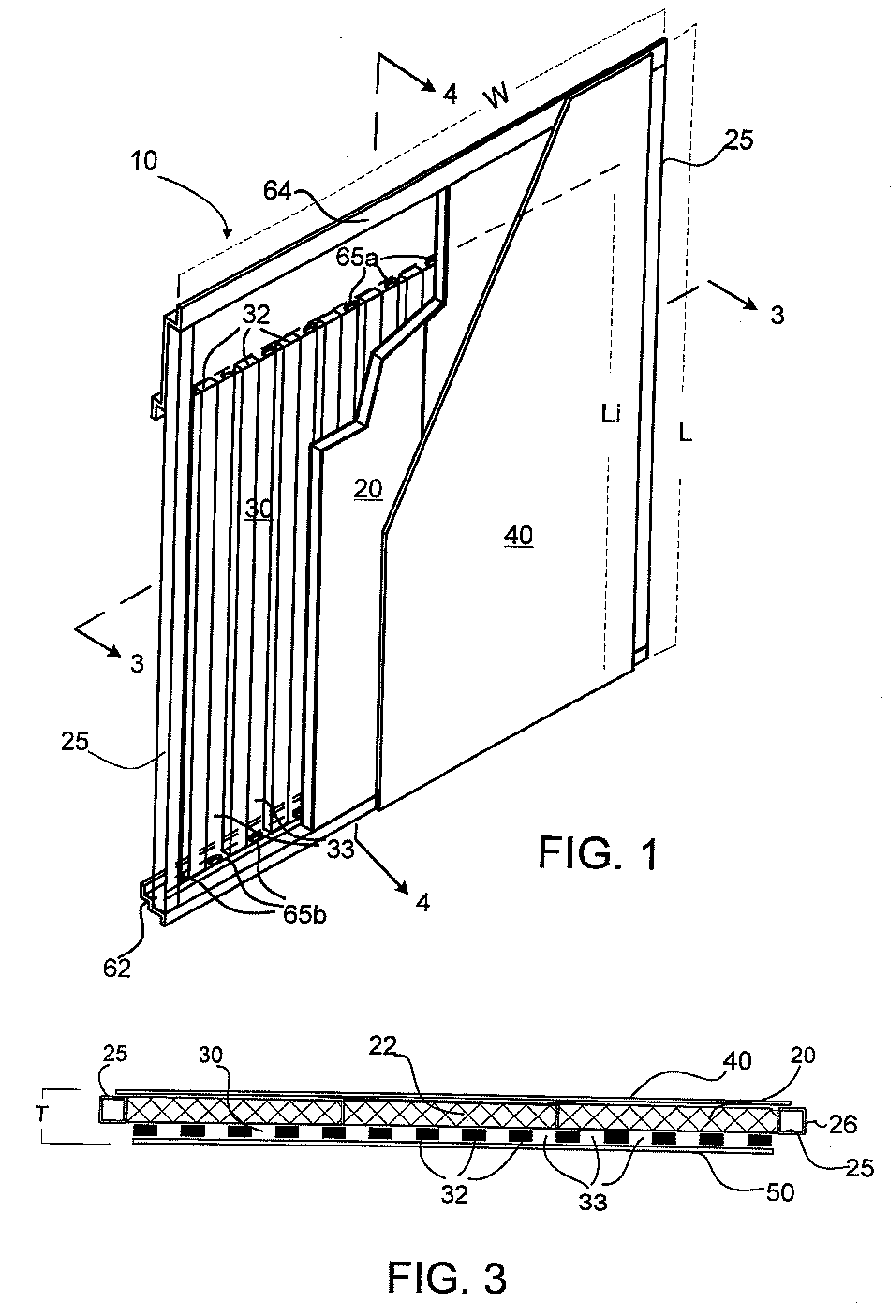

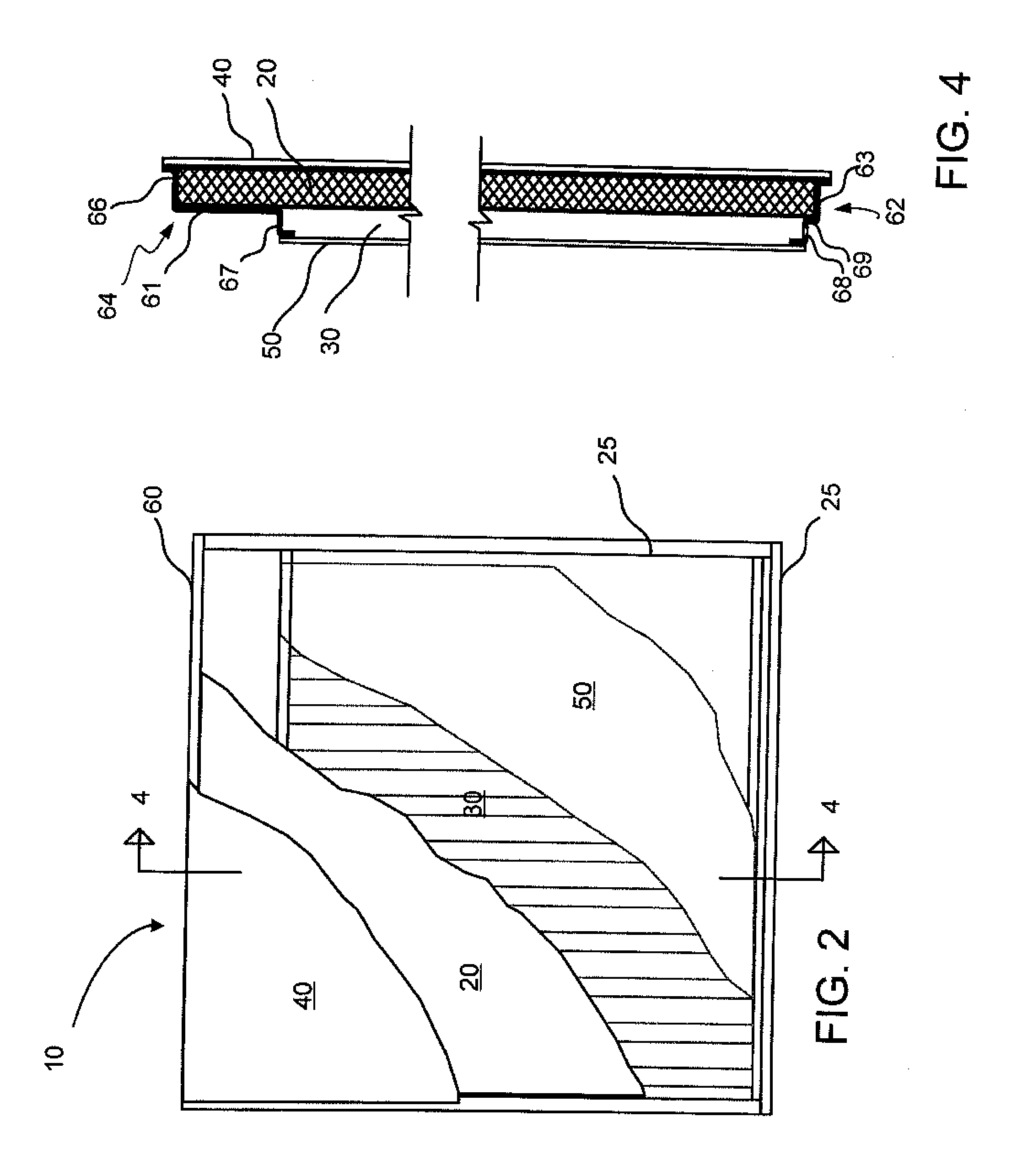

[0033]The present invention provides improved wall panels and improved methods for manufacturing the same. The panels of the invention comprise multiple layers, each designed to impart the panel a particular functionality and / or benefit, while the method of the invention for fabricating the multi-layer panel as one integral unit with no mechanical fasteners between elements, further imparts the panel structural stability and enhanced flatness and smoothness. In accordance with the novel method of the invention, the different layers of the panel are bonded to each other under pressure by one compression step rather than being fastened to each other by mechanical fasteners such as screws and bolts. Besides enhancing stability and appearance, this allows for manufacturing extra large panels which significantly reduces the number of joints and consequently reduces site work and cost as well as the amount of defects that might be introduced during joints assembling.

[0034]Referring to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com