Photocurable and thermosetting resin composition and printed circuit boards made by using the same

a thermosetting resin and composition technology, applied in the direction of photomechanical equipment, instruments, impression caps, etc., can solve the problems of reducing the tack-free properties of the contact exposure, the voluminous and high-cost facilities, and the reduction of the tack-free properties of the cured coating film, etc., to achieve high curing properties, excel in such properties as heat resistance, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

Synthesis of Carboxyl Group-Containing Photosensitive Resin

[0090]Into a three-necked flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux condenser, 217 g (1.0 equivalent weight) of cresol novolak type epoxy resin of which epoxy equivalent is 217 and which contains seven phenol skeleton residues in average per one molecule and also epoxy groups and 204.8 g of carbitol acetate were charged and they were molten by heating. To this mixture, 0.2 g of hydroquinone as a polymerization inhibitor and 1.0 g of triphenyl phosphine as a catalyst were added. To the resultant mixture, 72.0 g (1.0 equivalent weight) of acrylic acid was gradually added and they were left reacting for 16 hours at 85-105° C. To the resultant reaction product, 91.2 g (0.67 equivalent weight) of tetrahydrophthalic anhydride was further added to effect the addition reaction. The varnish obtained as described above was a viscous liquid containing 35 parts of carbitol acetate and confirmed to be ...

example 1

A Composition Containing the Component (B) Added to a Formulation Separated from that Containing the Components (A) and (C)

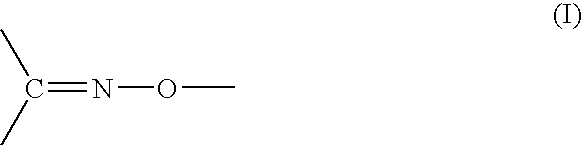

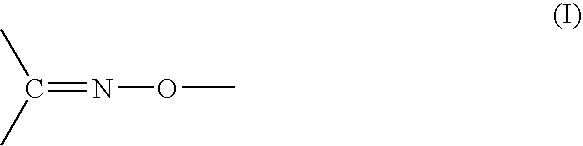

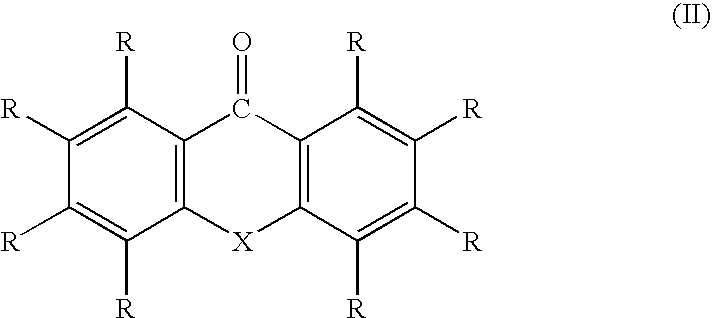

[0091]A composition was prepared by compounding 100 parts of the carboxyl group-containing photosensitive resin as the component (A) obtained in Synthesis Example 1 with 10 parts of dipentaerythritol hexaacrylate as the component (C), 1 part of an anti-foaming agent (AC-300 produced by Kyoeisha Chemical Co., Ltd.), 80 parts of barium sulfate, and 0.5 part of phthalocyanine green and then mixing and dispersing the resultant mixture with a three-roll mill. This composition is hereinafter referred to as liquid “A”. Another composition was prepared by compounding 5 parts of the photopolymerization initiator as the component (B) having the oxime linkage and represented by the aforementioned formula (IV) wherein R2 is methyl group with 1 part of diethyl thioxanthone (Kayacure DETX-S produced by Nippon Kayaku Co., Ltd.) as the component (B-I), 2.5 parts of ethyl 4-dime...

example 2

A Composition Containing the Component B Added to a Formulation Separated from that Containing the Components A and C

[0093]The liquid “A” and the liquid “B” of a photocurable and thermosetting resin composition were prepared under the conditions of the same formulations and the same procedures as used in Example 1 except that diethyl thioxanthone as the component (B-I) and ethyl 4-dimethylaminobenzoate as the component (B-II) were not used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com