Automated oil well test classification

a technology of oil wells and classification, applied in the field of oil well testing, can solve the problems of difficult to perform the analysis efficiently and in a timely manner, complex analysis of the data stream of well test data, and is primarily performed manually

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

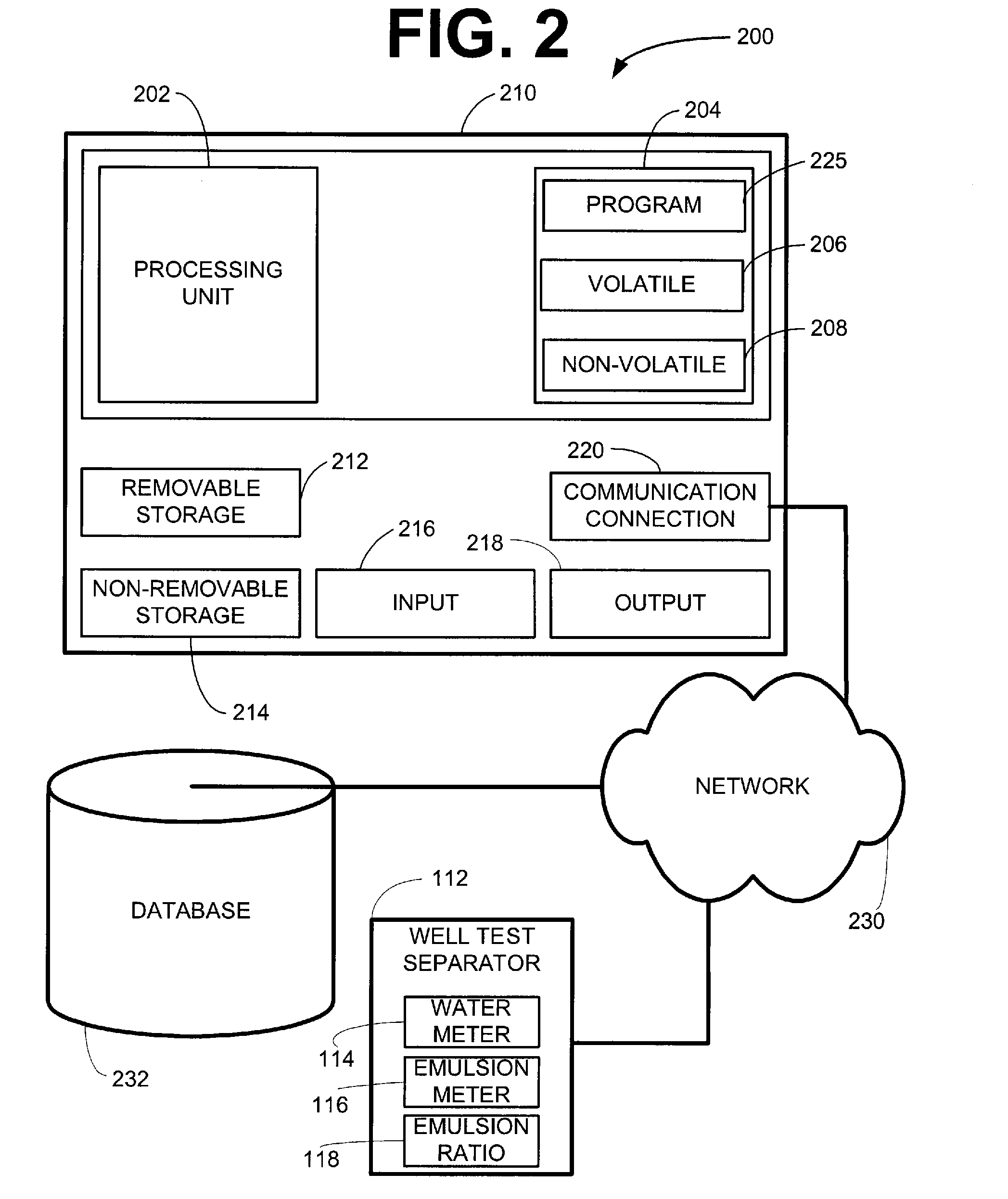

[0011]Various embodiments described herein provide systems, methods, and software for statistical analysis and classification of oil well tests. In one such embodiment, a system is composed of three parts. The first part is a repository of historical well tests that are provided with annotation added after manual review of the previous operation on a selected few representative wells. The second part is a set of classification models that do a comparison of a new test with the tests stored in the repository. These models, in some embodiments, are of three types: (a) models that match time series curves of oil and water flow rates with the curves stored in the repository; (b) models that compare long-term production trends on a given well with historical trends stored in the repository; (c) models that detect features of specific faults. The output of each model is a general indication of normality or abnormality of the new test, and may be accompanied by an indication of a specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com