Wall furniture mounting rail

a technology for wall furniture and mounting rails, which is applied to furniture parts, machine supports, and suspension devices, etc., can solve the problems of inconvenient installation of wall furniture, poor mounting effect, and inability to meet the needs of wall furniture, etc., and achieves the effect of convenient and fast installation of wall furnitur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

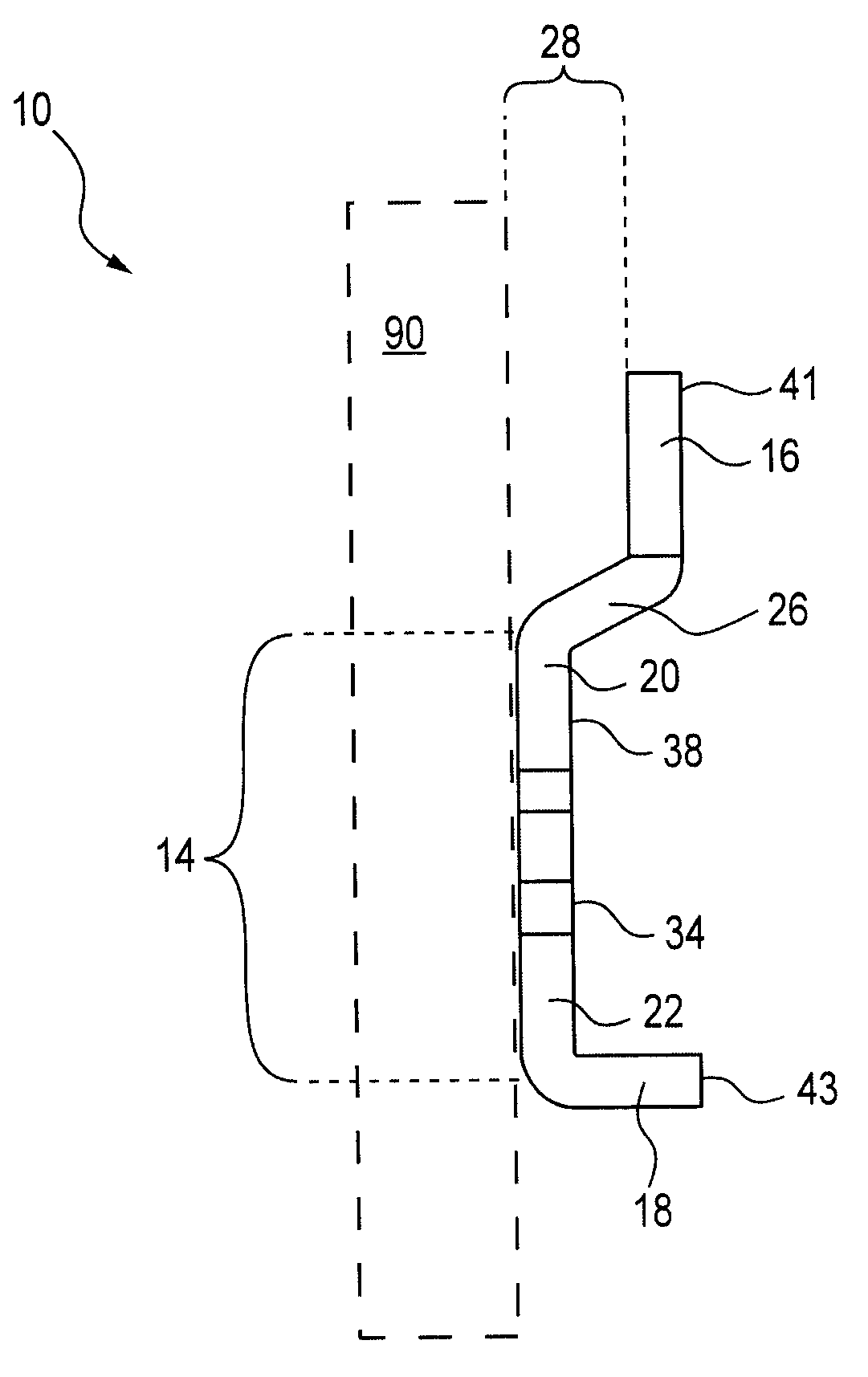

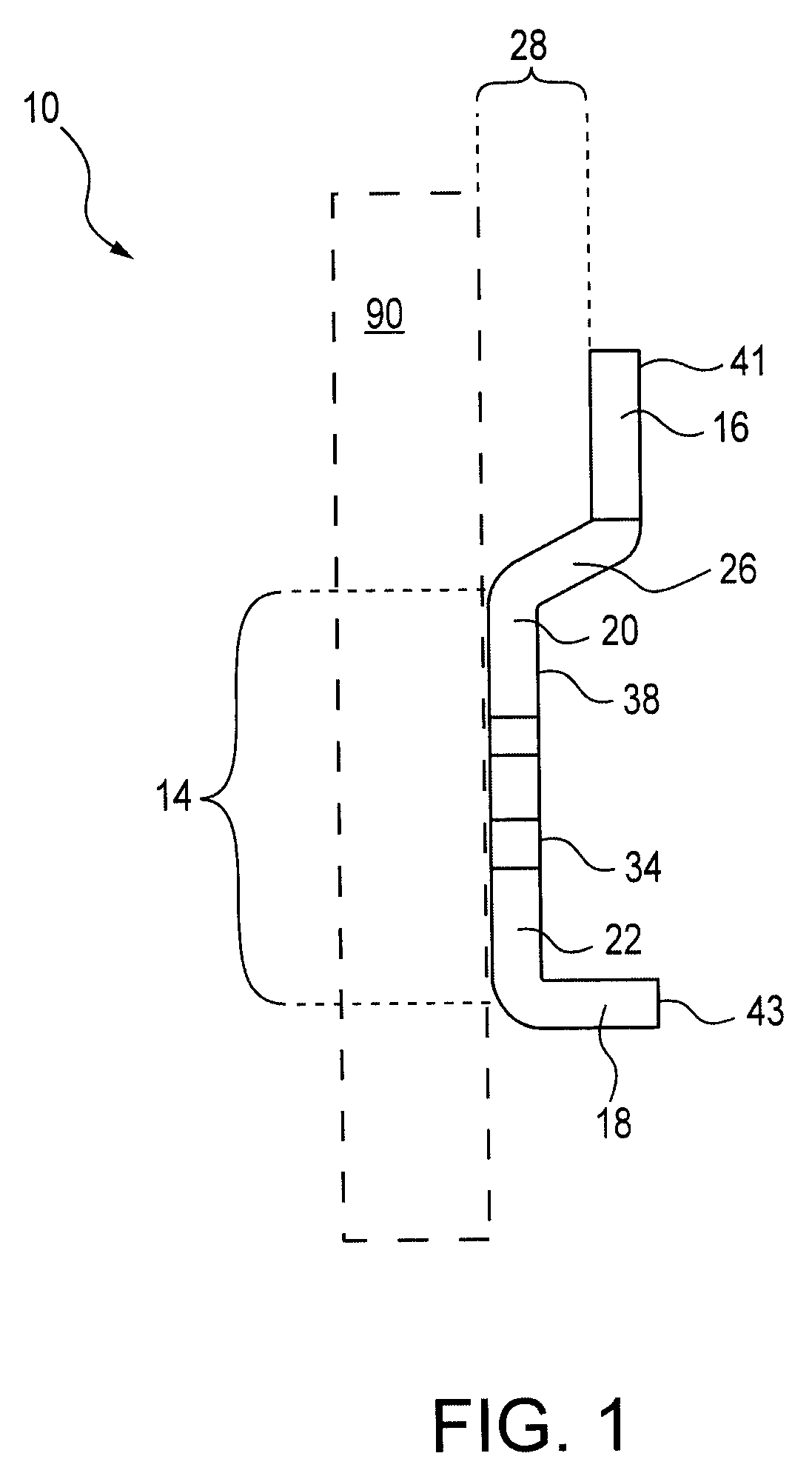

[0019]Referring to the drawings, and first to FIG. 1, a transverse cross-section of the present invention is shown. A mounting rail 10, in accordance with a preferred embodiment of this invention, is constructed of a durable material. The material may include a light weight metal, such as aluminum, or a more robust metal like steel or iron. The material may also be made of a metallic alloy, plastic, wood, or any other suitably stiff material.

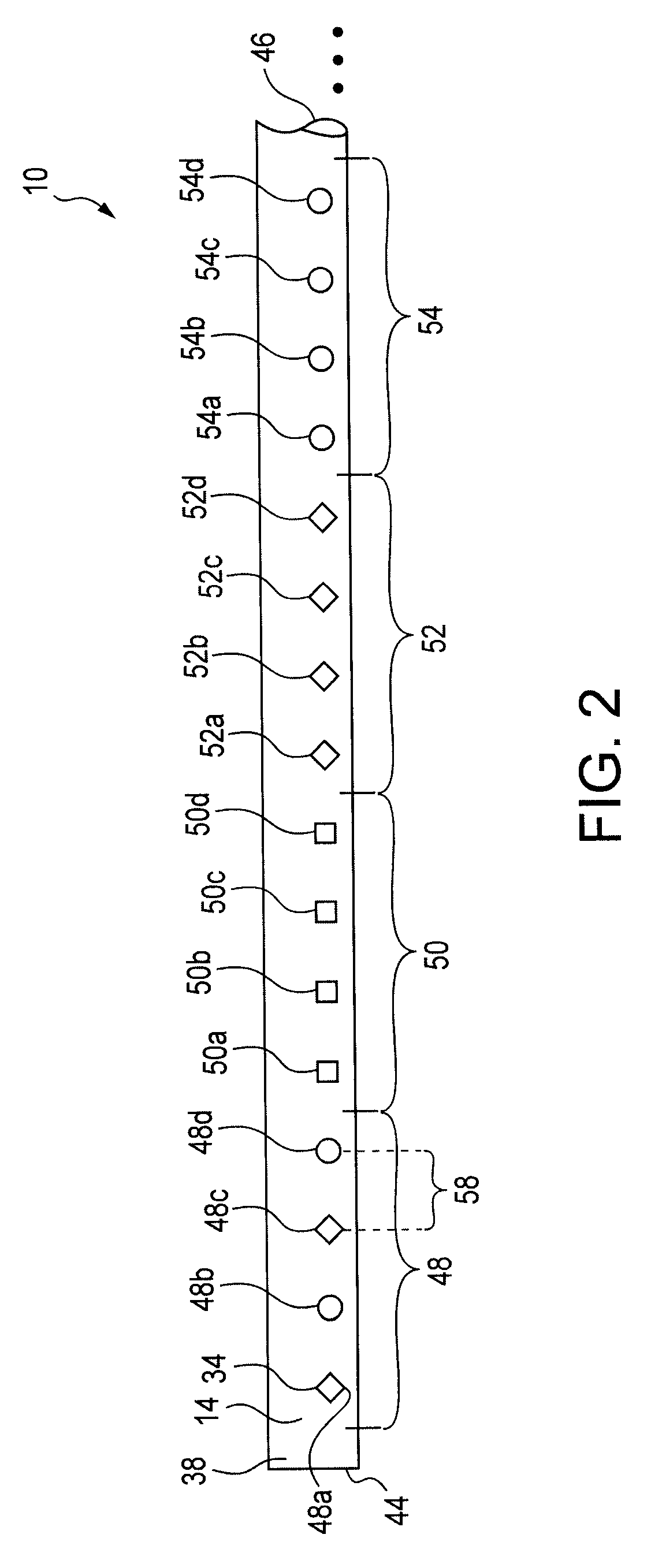

[0020]The mounting rail 10 is secured to a wall with fasteners through a plurality of apertures 34, which run through the wall anchor plate 14. Preferred fasteners include screws, nails, and rivets (not shown in the figures). A combination of adhesives and fasteners, such as screws and nails, may also be used for securing the mounting rail 10 to a wall. The mounting rail 10 is comprised of a wall anchor plate 14 disposed between and integral with a hook section 16 and a support section 18. The wall anchor plate 14 is planar and rests flush again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com