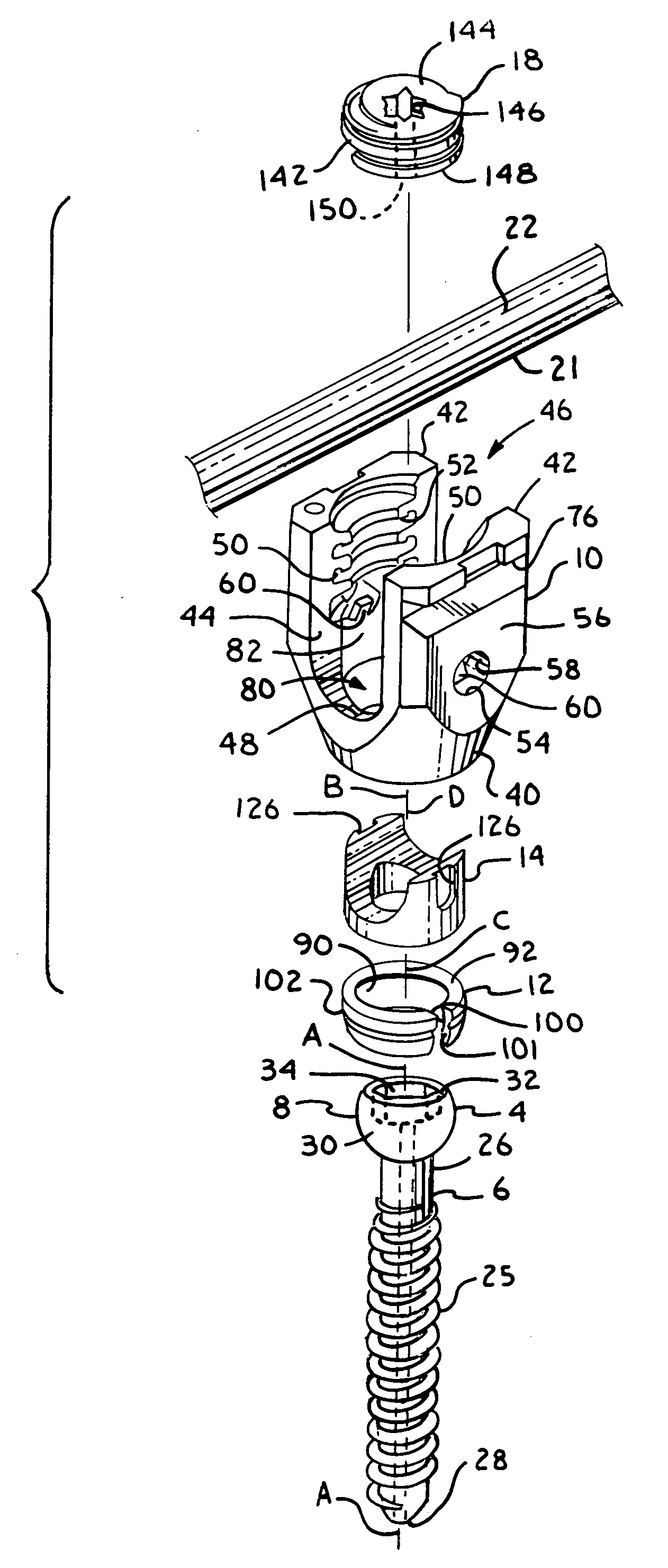

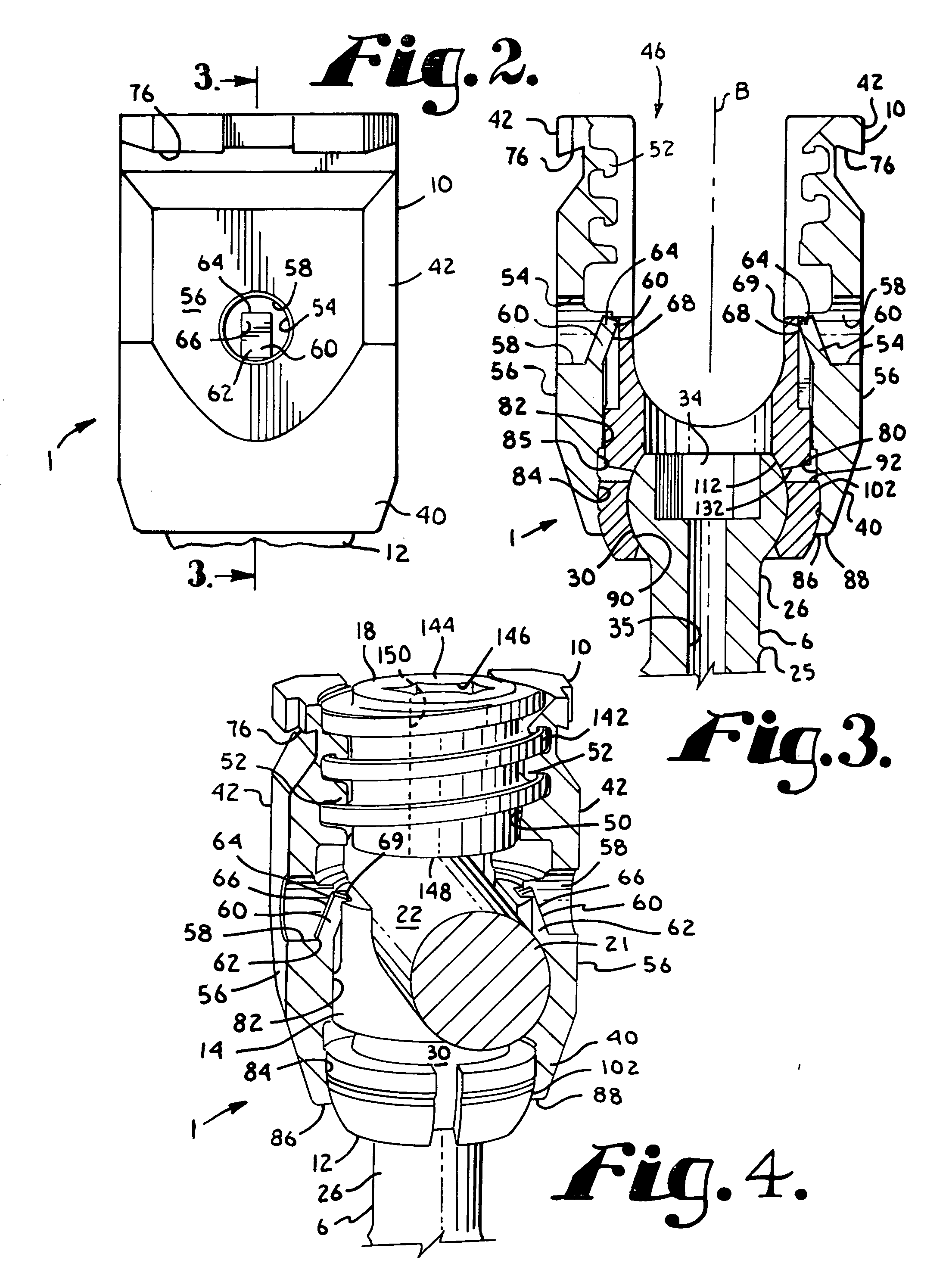

Polyaxial bone screw with spherical capture, compression and alignment and retention structures

a technology of spherical capture and bone screw, applied in the field of polyaxial bone screw, can solve problems such as difficult or impossible to do, and achieve the effects of low profile, easy use and inexpensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0073]With reference to FIGS. 15-21, a bone screw assembly of the invention, generally 301 includes a shank 304 that further includes a body 306 integral with an upper portion or capture structure 308; a head or receiver 310; a retainer 312 illustrated as an open collar-like retaining and articulating structure; and a compression insert 314. The shank 304, the receiver 310 and the retainer 312 are substantially similar to the respective shank 4, receiver 10 and retainer 12 previously described herein with respect to the assembly 1. The receiver 310 is sized and proportioned slightly differently than the receiver 12 to cooperate with the insert 314. However, the receiver 310 otherwise includes the same component parts previously described herein with respect to the receiver 10. In particular, the receiver 310 includes a central axis H, a base 340, arms 342, a U-shaped channel 344, an interior surface with a guide and advancement structure 352, a pair of opposed apertures 354 upwardly...

fourth embodiment

[0079]With reference to FIGS. 23 and 24, in a fourth embodiment according to the invention, generally 401, a receiver 410 is substantially identical to the receiver 310 of the assembly 301 with the exception that the spring tabs 360 are removed and replaced with a deformable material portion 460. The assembly 401 otherwise includes a shank 404, a retainer 412 and a compression insert 414 identical or substantially similar to the shank 304, retainer 312 and compression insert 314 previously described herein with respect to the assembly 301. Formed on outside surfaces 456 of the receiver 410 are a pair of opposed apertures 457. Each deformable portion or wall 460 partially defines the respective aperture 457. A tool (not shown) is inserted into the aperture and is pressed against the deformable portion 460, causing the portion 460 to extend into a cavity 480 of the receiver 410 in a direction towards a central axis J. Similar to the spring tabs 360, the now deformed wall portions 460 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com