Small Vessel Capable Of High Tow Force

a small watercraft and high towing force technology, applied in the field of watercraft, can solve the problems of increasing the limitation of conventional small watercraft for towing high forces, unstable craft, and vessel instability, and achieve the effects of reducing the impact of towing force on the stability and resistance of watercraft, reducing the chafing, and reducing the chafing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

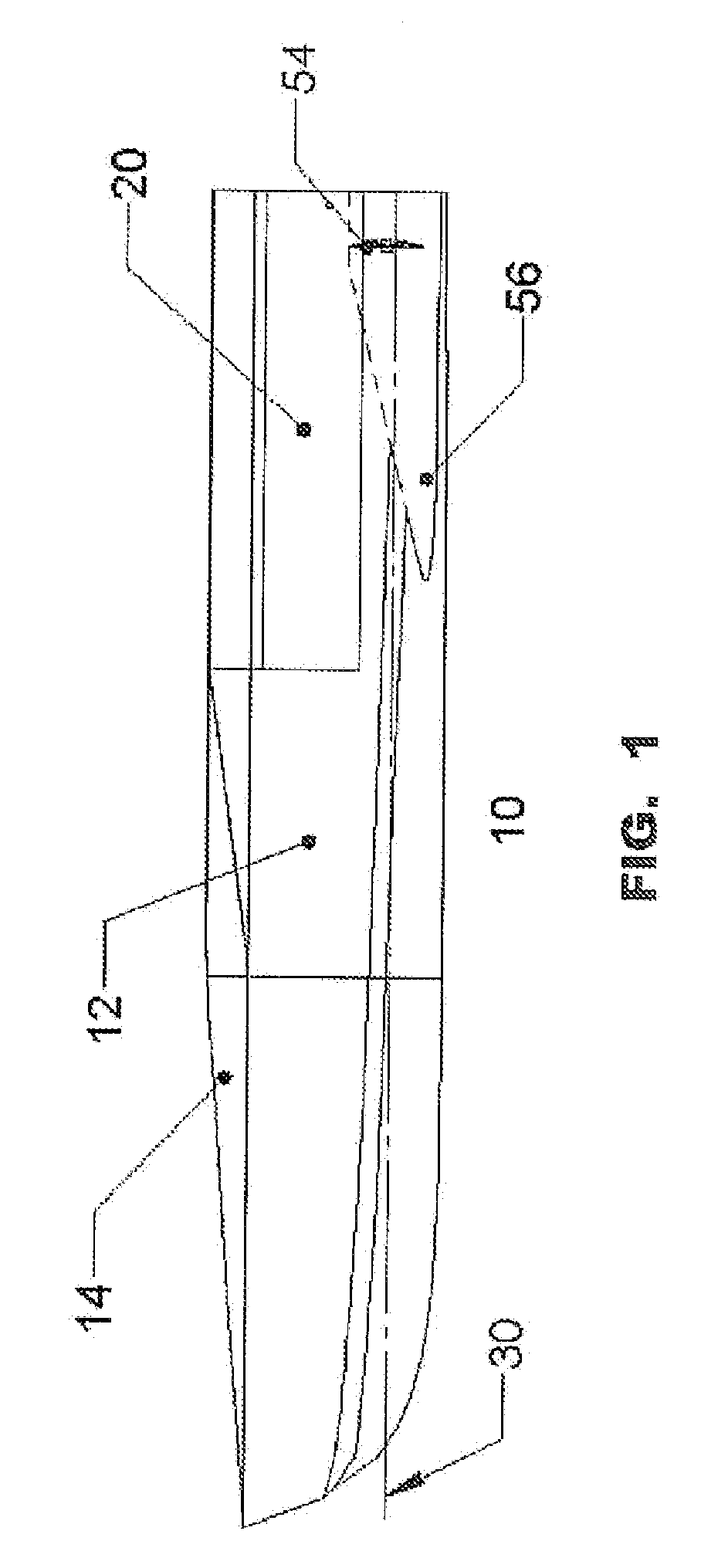

[0025]Referring now to the drawings wherein like characters designate like or corresponding parts throughout the several views. A semi-planning hull is shown in all of the implementations to simplify the figures. The present invention can be readily applied to other hull forms or shapes. FIG. 1 shows a side view of the watercraft 10 with payload mounting area 20 empty. The hull plating 12 is joined to the deck plating 14 to form a watertight boundary to prevent water from entering the craft in the event of a wave washing over the deck or the craft capsizing due to large wave impact. The design waterline is indicated by 30. The propellers 54 are recessed in tunnels 56 to protect them from damage due to impacting objects in the water.

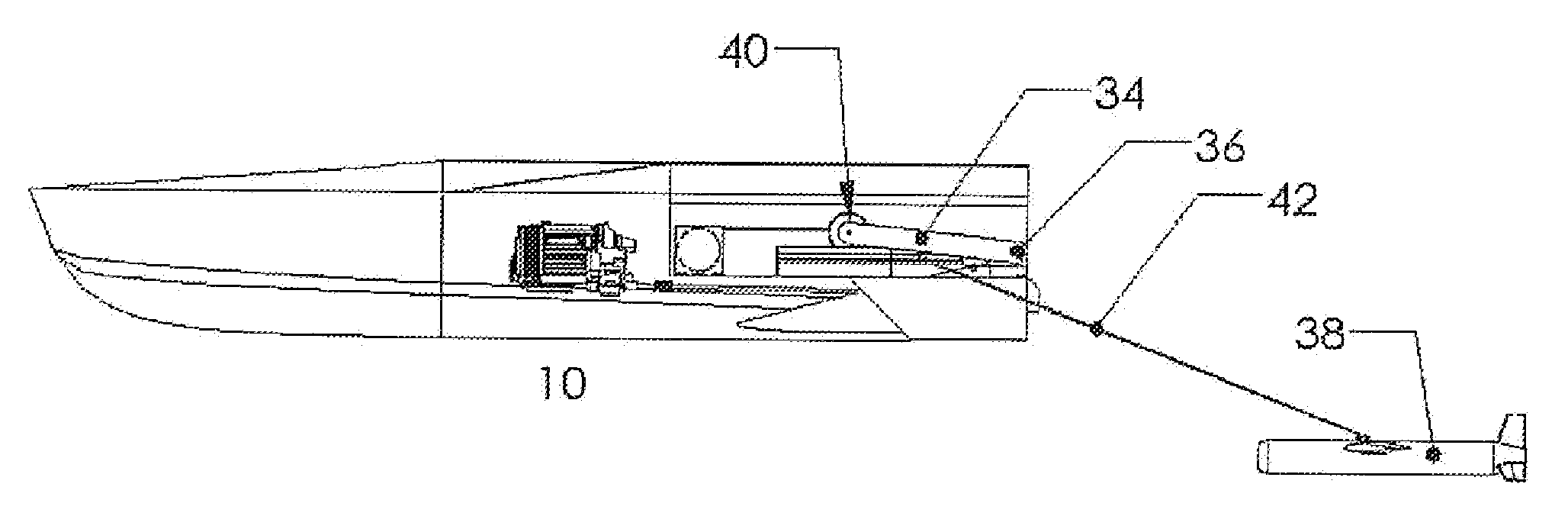

[0026]FIG. 2 is a section view showing the arrangement of the major components. The engines 50 are located forward of the payload area as close to the hull plating as possible. The engine exhaust 51 discharges through the side of the hull. The drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com