Multilayered insole for footwear

a multi-layer, insole technology, applied in the direction of insoles, uppers, bootlegs, etc., can solve the problems of bad air permeability and air permeability of insoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

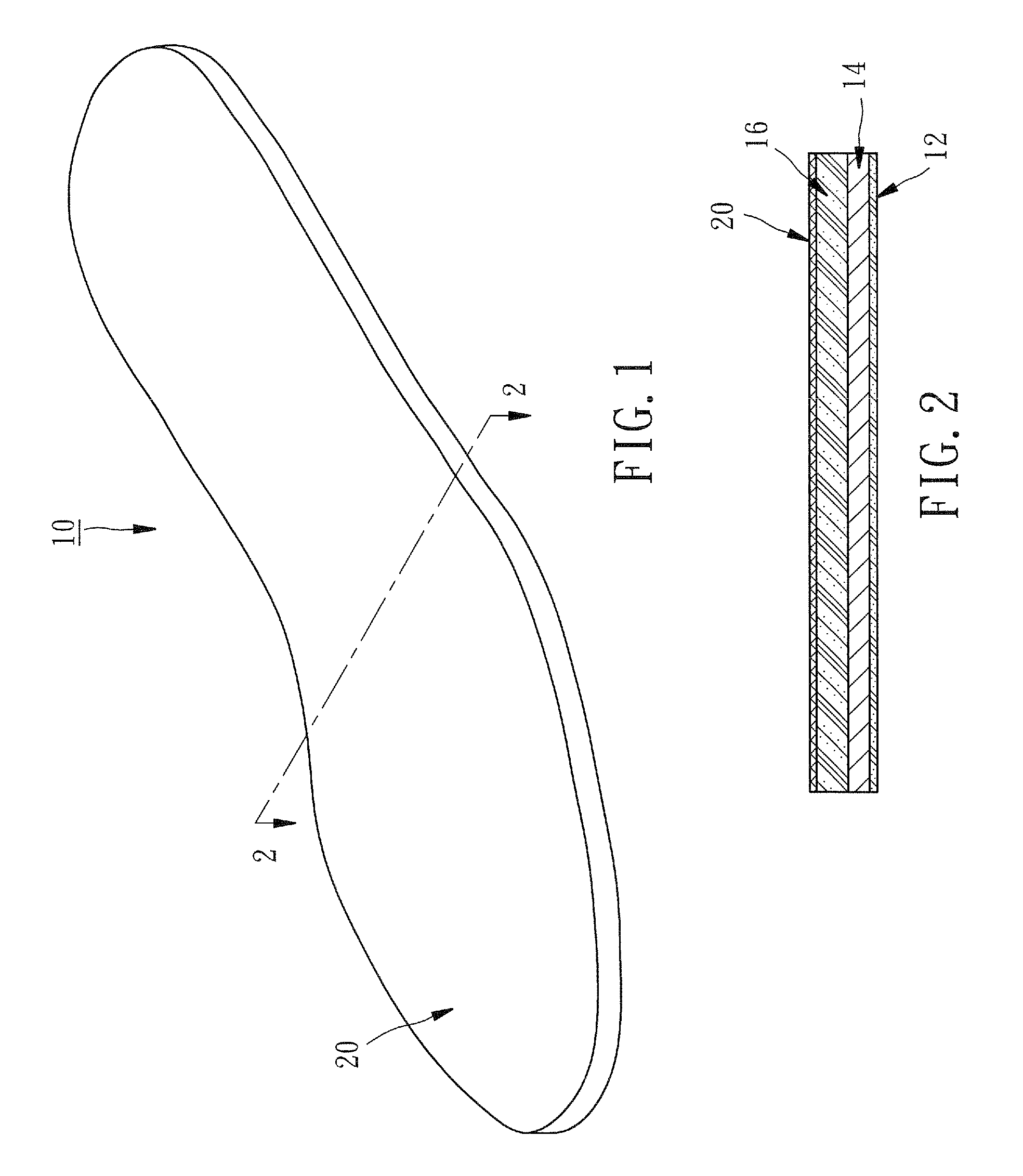

[0011]Referring to FIGS. 1 and 2, the insole 10 of the present invention generally comprises a base layer 12, an intermediate layer 14, an upper layer 16 and a top layer 20.

[0012]The base layer 12, which is made of a first foamable material formed by a foamable polyurethane resin, is preferably of generally flat construction with a thickness of 0.5 mm. The base layer 12, for having a thickness specially designed and being made of a foamable material not mixed with any other materials, has a better resistance to compression than any other foamable materials so as to provide a high retention rate of cushioning properties after wear.

[0013]The intermediate layer 14 is adhered to an upper surface of the base layer 12 and preferably is of generally flat construction. The intermediate layer 14 is made of a second foamable material formed by a foam polyurethane resin mixing with recycled polymeric foam materials. Such a foamable material, for being mixed with recycled polymeric foam materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com