Collapsible hoop

a collapsible, hoops technology, applied in the field of hoops, can solve the problems of sudden deployment of pre-stressed hoops, difficulty in storage and tote, and difficulty in storing and toting around, and achieve the effect of suitable rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

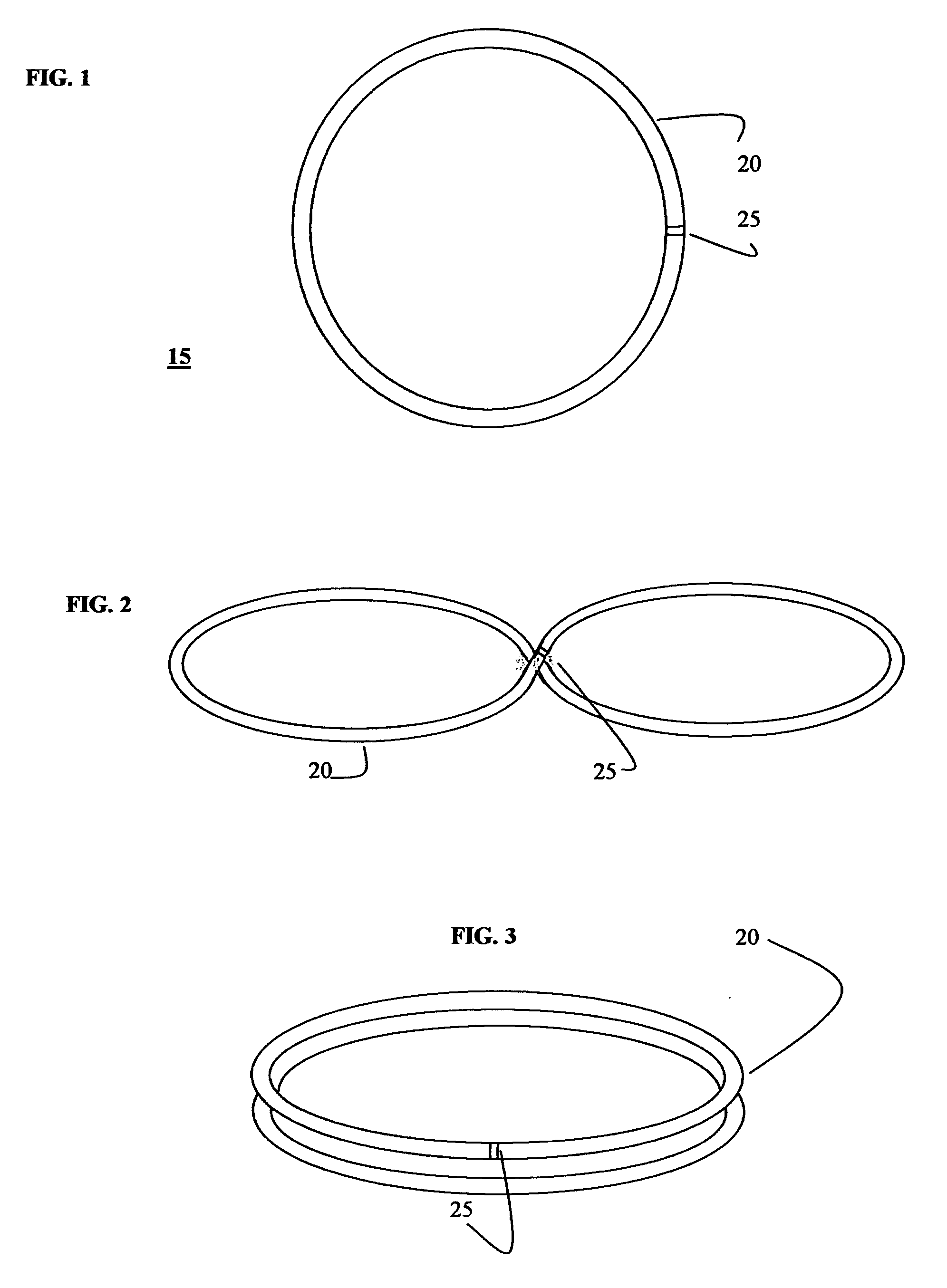

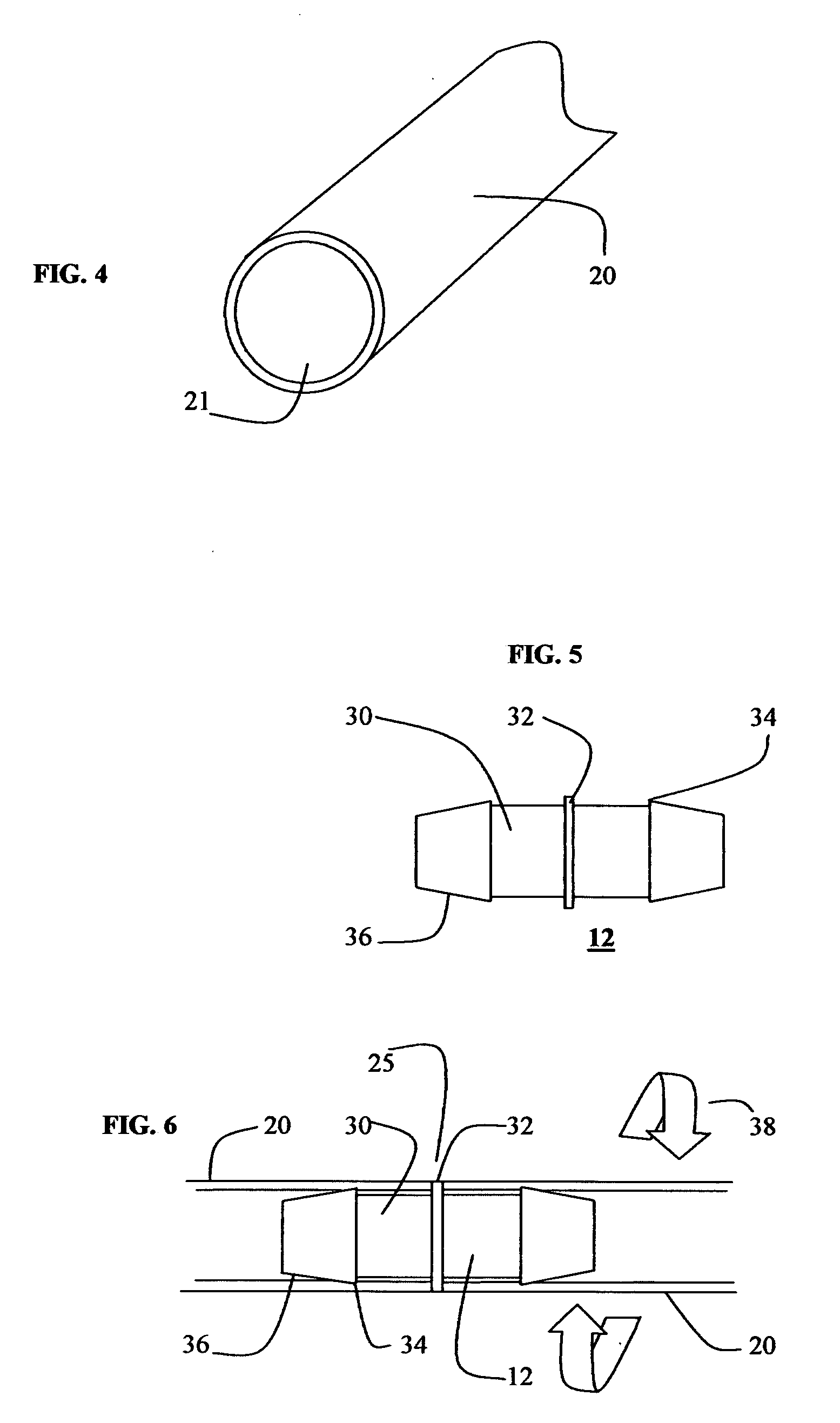

[0021]Referring to FIGS. 1-6. Referring to FIG. 2 a pre-coiled linear length of plastic tubing is shown that may have an over-all length of approximately 96 inches. A 96 inch tube will form a hoop roughly 30 inches in diameter. FIG. 5 shows a tube mating union or coupling 12 that is designed to be forcibly inserted or threaded inside the ends of tube 20. That is to say that the outside diameter of the threading 34 is a larger diameter than the inside diameter of tube 20. The sharp metal threads of coupler 12 will cut into and seat in the softer plastic material of the tube 20 preventing the coupling from being pulled out after assembly yet allowing for rotation of the tube around the threaded metal coupling. Referring to FIG. 4. When tube 20 is manufactured as in an extrusion process the material, while still hot, can be formed into a continuous coil with an approximate diameter of 14 to 20 inches and allowed to cool in that condition. A collapsed hoop can then be assembled from thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com