Device for winding suspension cord of blind

a technology for suspension cords and blinds, which is applied in the direction of door/window protective devices, shutters/movable grilles, wing arrangements, etc., can solve the problems of unsuitable large-size blinds or long suspension cords, complicated structure for winding suspension cords, and limited space for roller shade bars to move in an axial direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

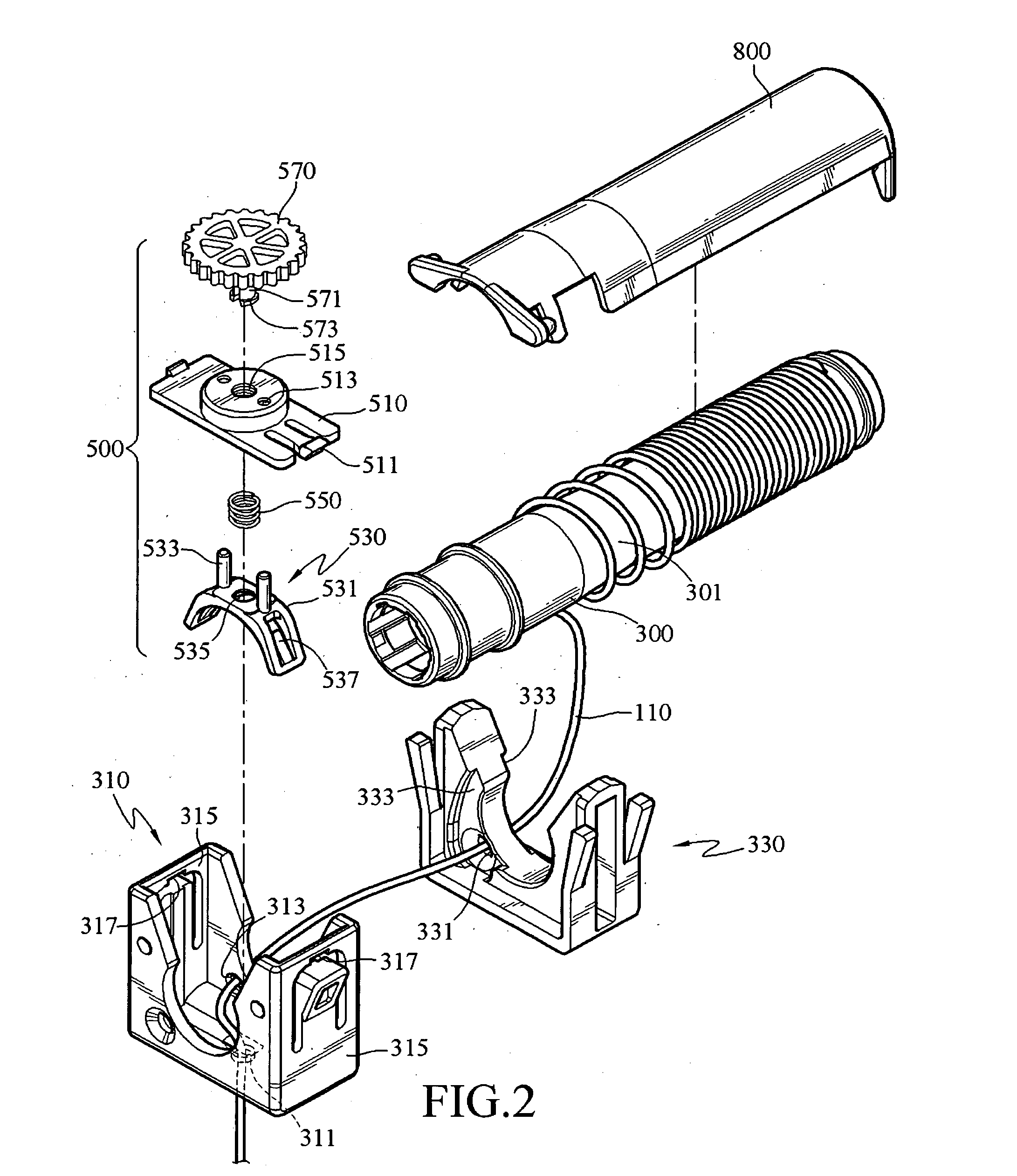

[0031]Please refer to FIGS. 4A and 4B of a schematic view of the connection and a schematic view of the operation of the adjusting means and the pedestal in the present invention. As shown in FIGS. 2, 4A, and 4B, the adjusting means 500 includes a fixed plate 510, a tablet 530, a resilient element 550, and a knob. The fixed plate 510 has a bump 511 extending from both ends thereof. A hole 317 is respectively opened in the two side walls 315 of the pedestal 310, such that the bumps 511 of the fixed plate 510 is buckled in the holes 317 and then the fixed plate 510 is buckled in the pedestal 310. A through hole 513 is opened in the fixed plate 510 along the side wall 315. The tablet 530 is an arc plate 531, and a sliding bar 533 extends from one side of the arc plate 531. The sliding bar 533 penetrates through the through hole 513, such that the tablet 530 may slide up and down with respect to the fixed plate 510. When the fixed plate 510 is fixed on the pedestal 310, the tablet 530 p...

second embodiment

[0037]Please refer to FIG. 5 of a schematic view of the connection of the adjusting means and the pedestal in the present invention. As shown in FIG. 5, the fixed plate 510 and the pedestal 310 are integrally formed. Therefore, a through hole 318 and a bolt hole 319 are opened in one side wall of the pedestal 310 opposite to the adjusting means 500, and the relationship between the pedestal 310 and the adjusting means 500 is the same as that in the above-mentioned embodiment and will not be described any more.

third embodiment

[0038]Please refer to FIG. 6 of a schematic view of the connection of the adjusting means and the pedestal in the present invention. As shown in FIG. 6, a through hole 318 and a bolt hole 319 are formed in one side of the pedestal 310. The adjusting means 500 includes a tablet 530 and a knob 570. The tablet 530 has a sliding bar 533 extending from one end thereof, wherein the sliding bar 533 passes through the through hole 318, such that the tablet 530 is fitted on the pedestal 310 and may slide vertically, and the lower end of the tablet 530 presses against the surface of the cord surface 300. The knob 570 has a screw axis 571 extending from one end thereof, and the screw axis 571 is screw-connected to the bolt hole 319 and pivoted to the tablet 530 with the back end thereof. A collar 575 is further disposed above the tablet 530 to prevent the tablet 530 from dropping outside the rotating shaft 571. As such, the tablet 530 may adjust the pressure generated when the tablet 530 press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com