Aggregate for a washing machine with a plastic sudsing container

a technology for washing machines and containers, applied in washing machines with receptacles, other washing machines, textiles and paper, etc., can solve the problems of polymer breaking, not being useful, and not being known

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

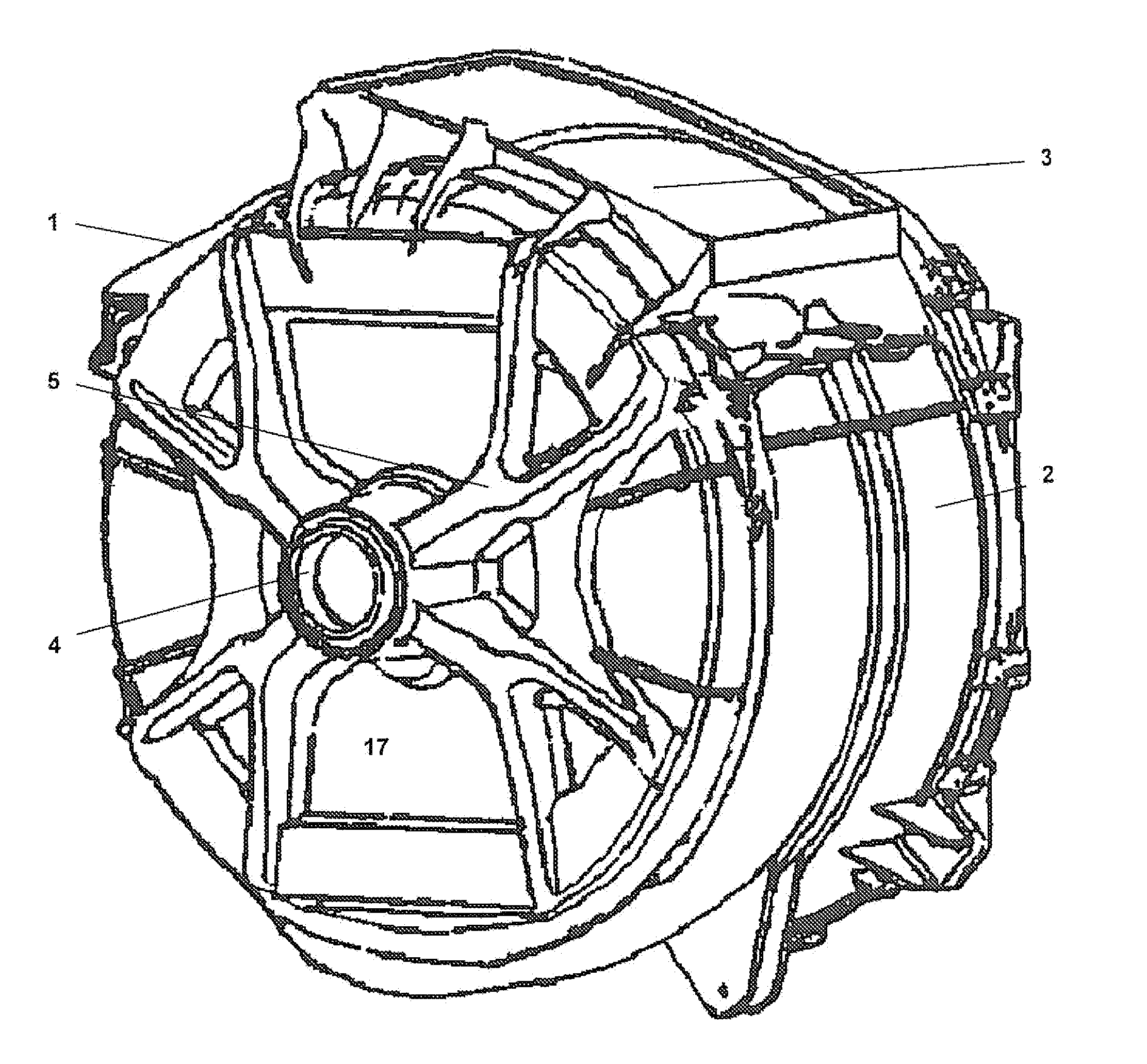

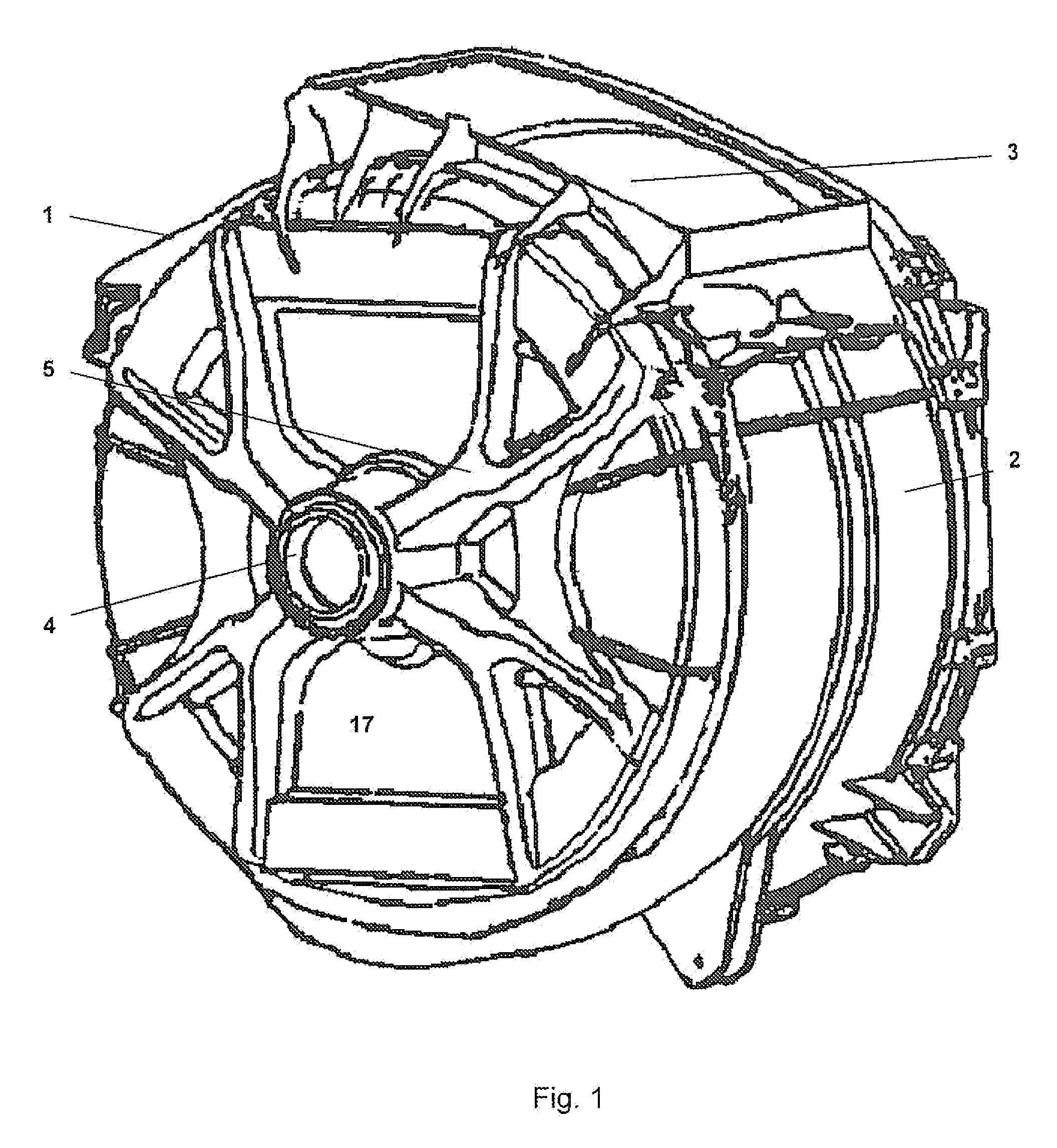

[0025] The sudsing container 1 shown in FIG. 1 is used in connection with an aggregate of a washing machine which is loaded through a circular shell 2 of the sudsing container 1, the shell 2 being provided for this purpose with an opening 3 aligned with an opening (not shown) of a washing drum (not shown). Such washing machines are sometimes referred to as top loaders. It will be understood by those skilled in the art, that if the suds container 1 were a component of washing machine loaded from its front, the openings would be provided in the front walls of the suds container and washing drum, respectively.

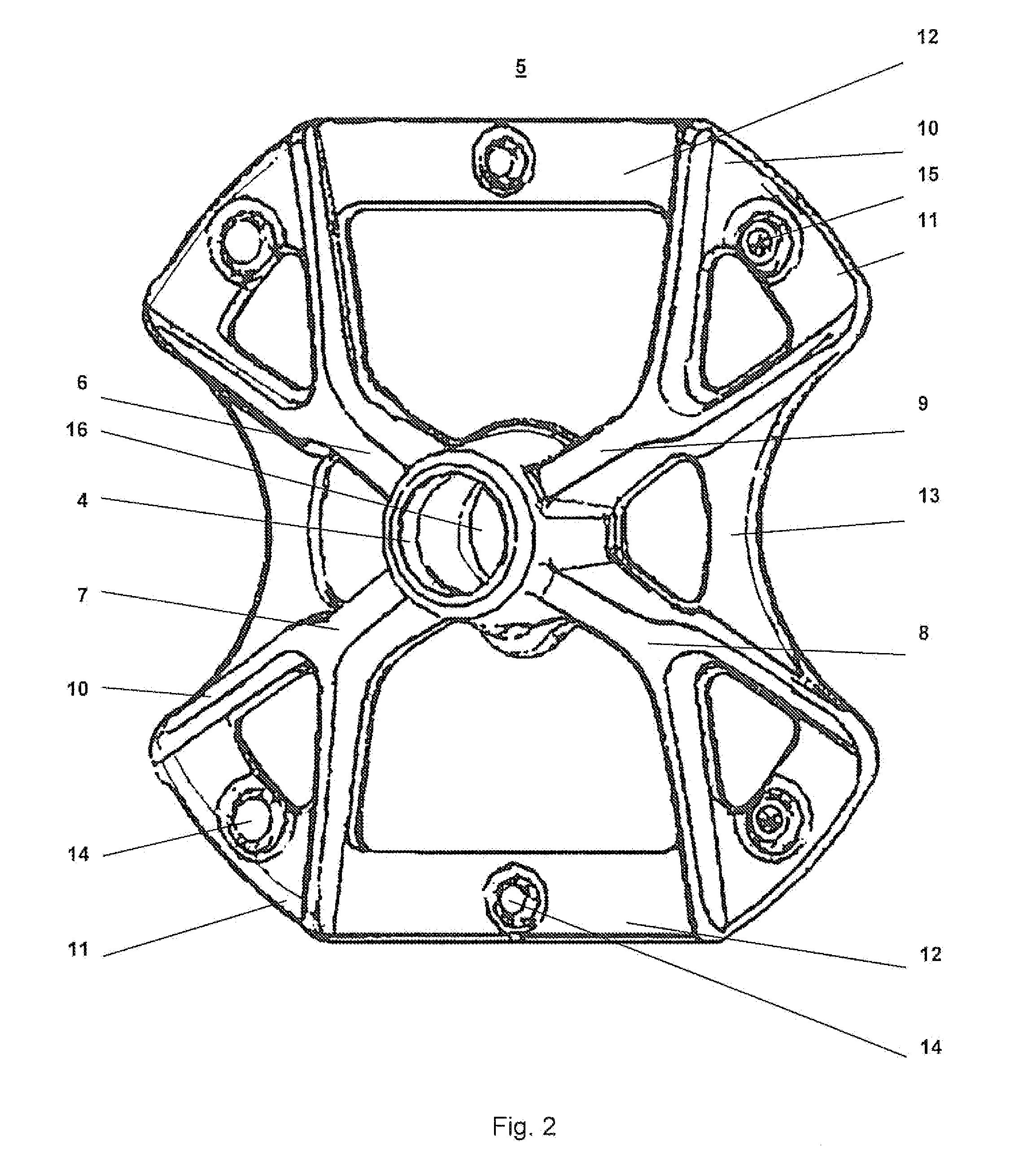

[0026] As is well known, the drum, for its cantilevered bearing support, is provided with a shaft which is received within two spaced bearings (not shown). The bearings are disposed in a tubular bearing seat 4 which is position in the center of a support structure 5 shown in detail in FIG. 2. The support structure 5 is provided with at least one, but, preferably with several radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com