Snow guard for roofs

a technology for roofs and snow guards, applied in the field of snow guards for installation, can solve the problems of accumulating snow on roofs, affecting the safety of people,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

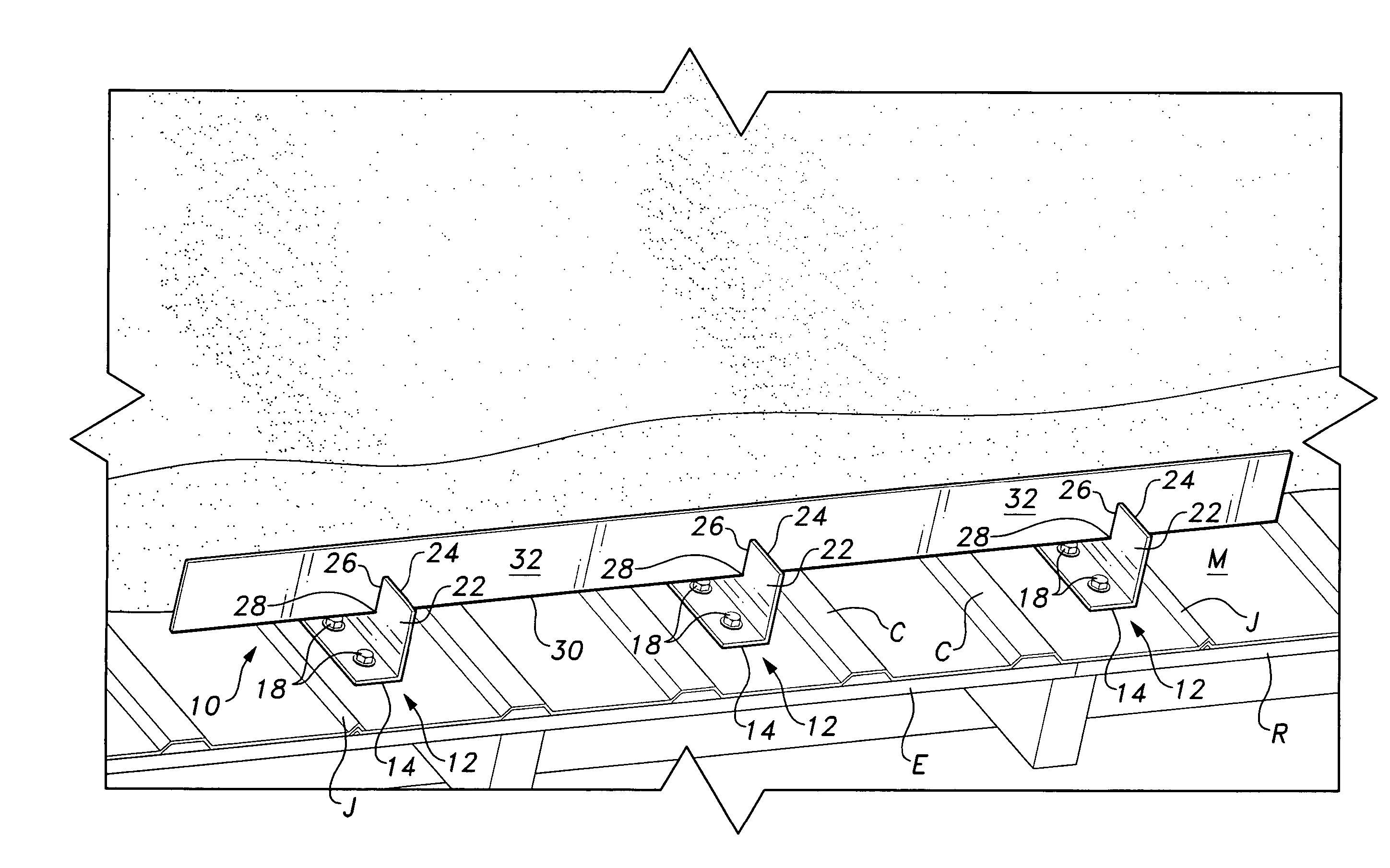

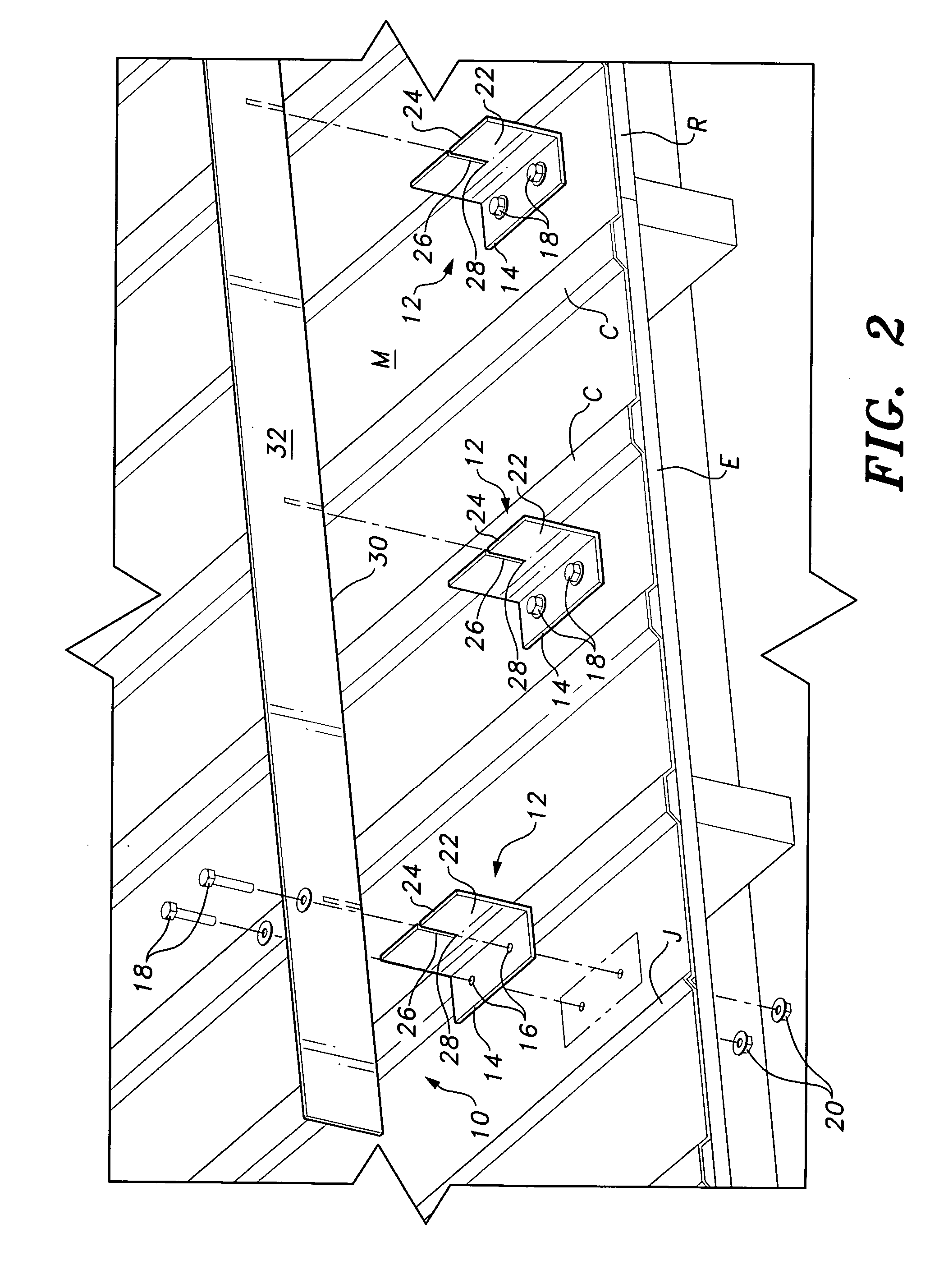

[0018] The present invention comprises various embodiments of a snow guard for roofs, serving to prevent random or accidental slippage of snow from a sloped roof, yet allowing a user of the snow guard to deliberately remove snow from the roof as needed. While the snow guard is particularly adapted for use on roofs having sheet metal sheathing or corrugated roofing, it may be used with other types of roofs as well, if so desired.

[0019]FIG. 1 of the drawings provides an environmental perspective view of the snow guard 10 in an exemplary installation on a sloped or gabled roof R covered with sheet metal sheathing M. Such metal sheathing M is generally provided with additional stiffening corrugations C and overlapping seams or joints J, which are raised above the surface of the sheet metal M. The snow guard 10 includes a series of spaced apart snow fence mounting brackets 12, which are attached to the structure of the roof R, preferably through the eaves E to the exterior of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com