Fan blade assembly for electric fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

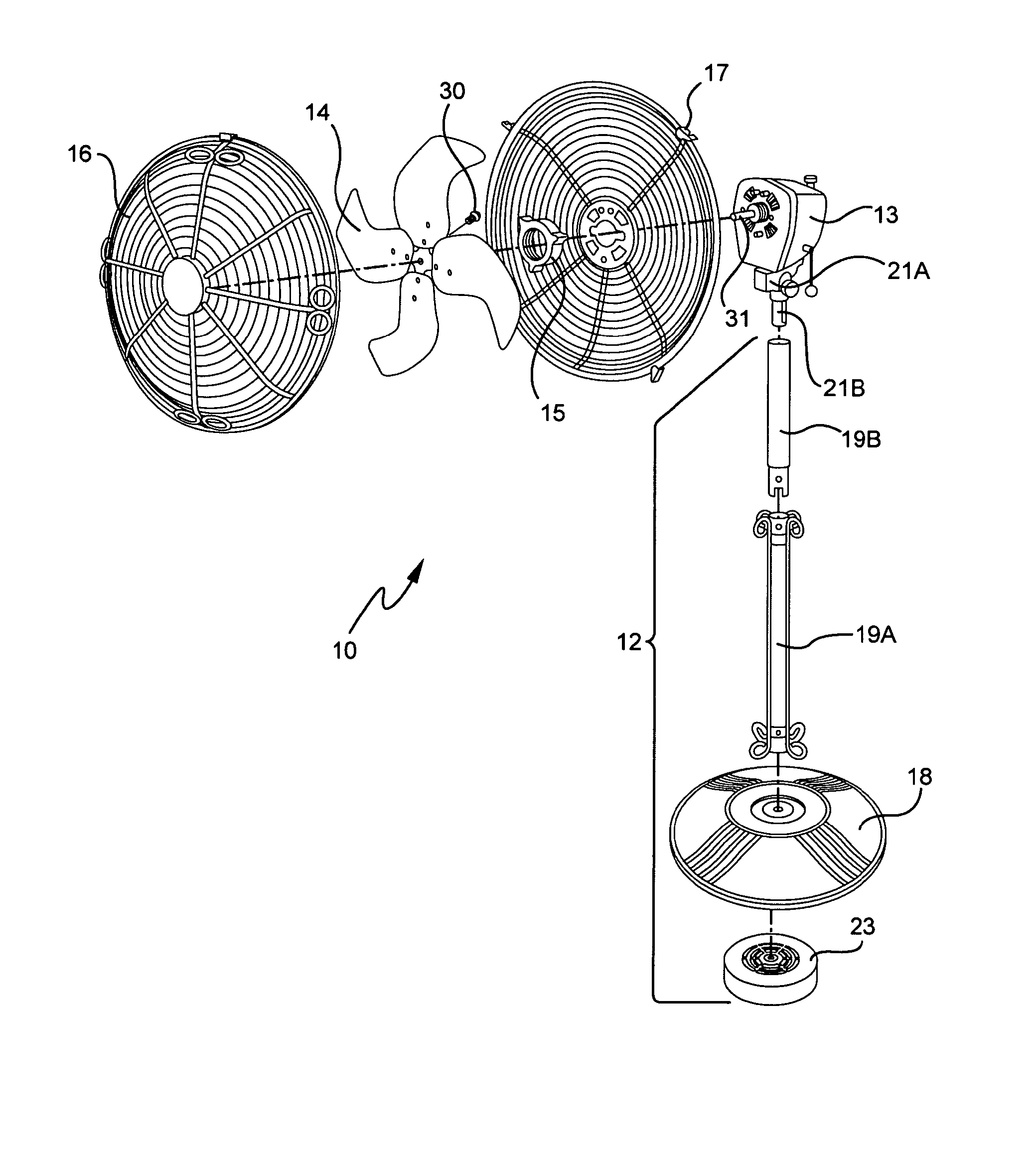

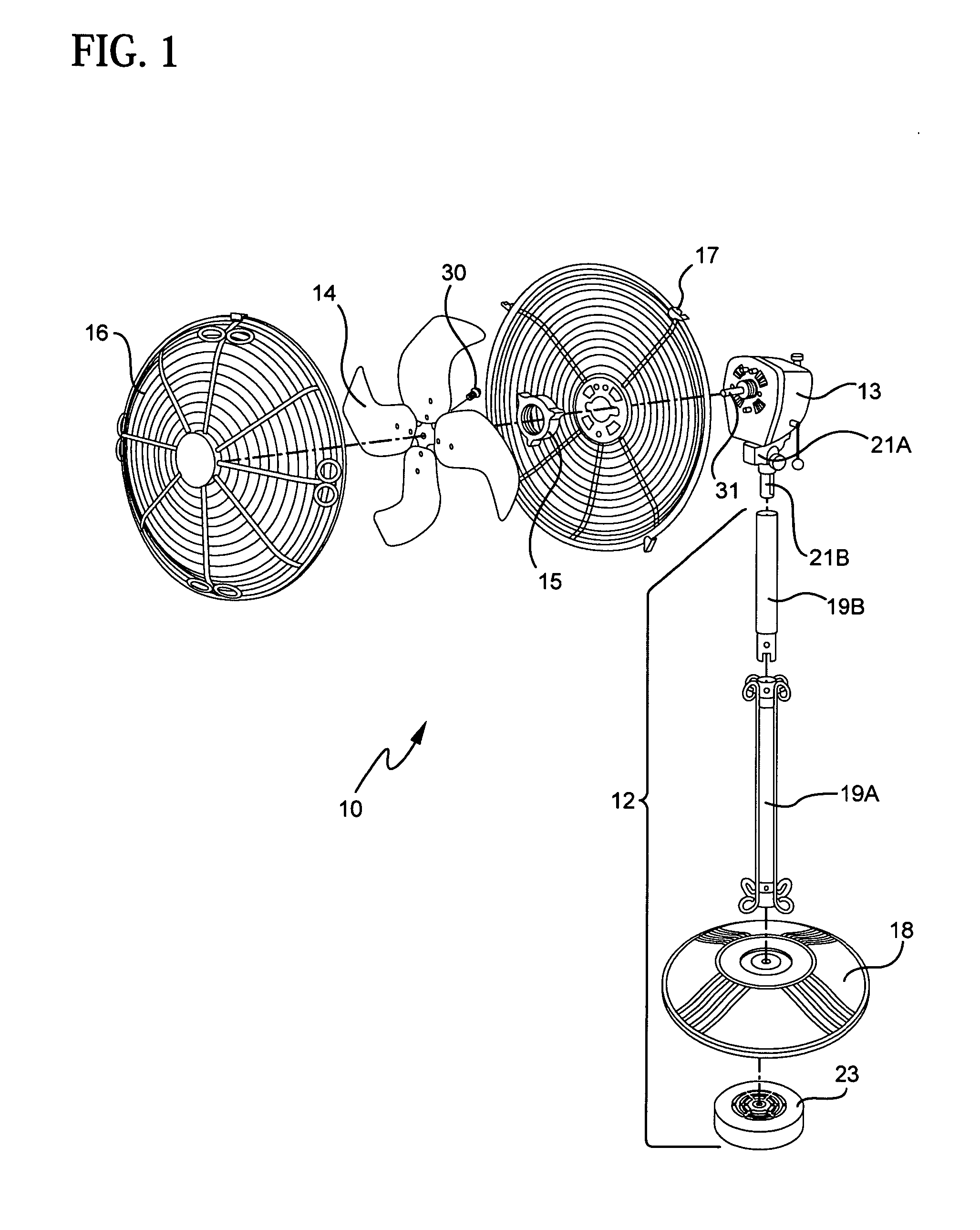

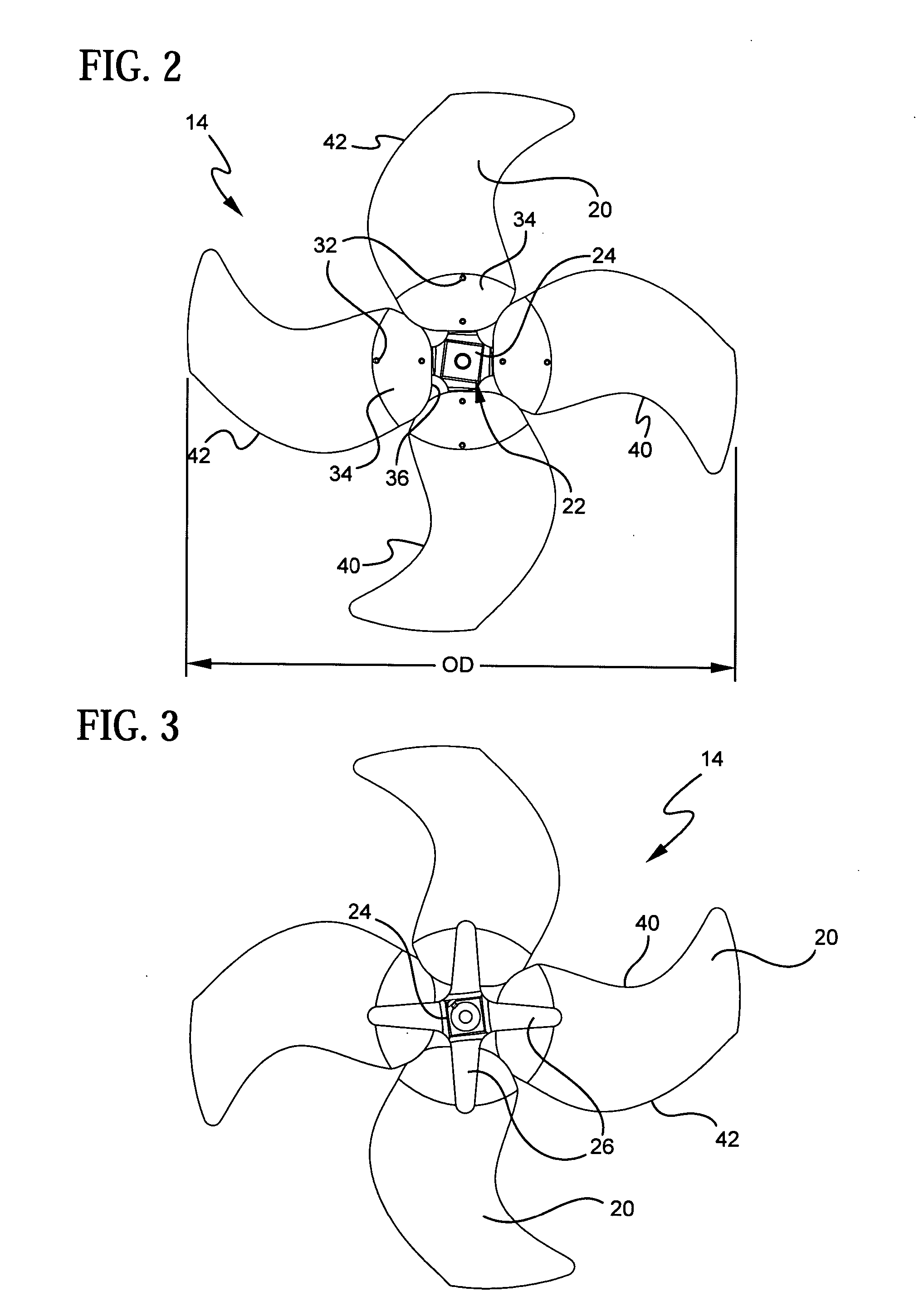

[0030] A portable electric fan 10 according to the invention is shown in FIG. 1. The fan includes a support 12, an electric motor assembly 13 mounted to the support, a fan blade assembly 14 operatively associated with the electric motor assembly 13, and a grill 16 enclosing the fan blade assembly. The grill includes two halves that are connected by wing clips 17. A grill nut 15 connects the rear half of the grill to the housing for the motor assembly 13. This type of fan 10 is known as a stand fan. The support includes a base 18, a long extension pole 19A coupled to the base, and a short extension pole 19B. The short extension pole 19B has a lower end of reduced diameter that extends within the top end of the long pole 19A. A set screw is employed to lock the poles together. The motor 13 is coupled to the top end of the short pole 19B by a bracket 21 A including a neck 21B. The neck 21B extends into the top end of the short pole 19B and is affixed thereto by a set screw. A weight 23...

second embodiment

[0039] A fan blade assembly 114 according to the invention is shown in FIGS. 9 and 10. The assembly includes five identical blades 120 that are secured to a central hub 122. The hub 122 includes a generally hemispherical body. The rear side of the hub includes five pairs of threaded openings (not shown) used for securing the blades 120. It further includes a center opening 124, as shown in FIG. 11, for receiving the shaft of a motor (not shown).

[0040] Each blade 120 is preferably made from aluminum and has a substantially uniform thickness. In this embodiment, the thickness of the airfoil portion of the blade is about 1.5 mm. As discussed above with respect to the first embodiment, the blade thickness can vary over a range without materially affecting performance. The blade includes an inner or root portion 134 that may or may not have the same thickness as the airfoil portion of the blade. The inner portion includes a curved inner edge 136 and a generally arcuate boundary 138 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com