Tray for component packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

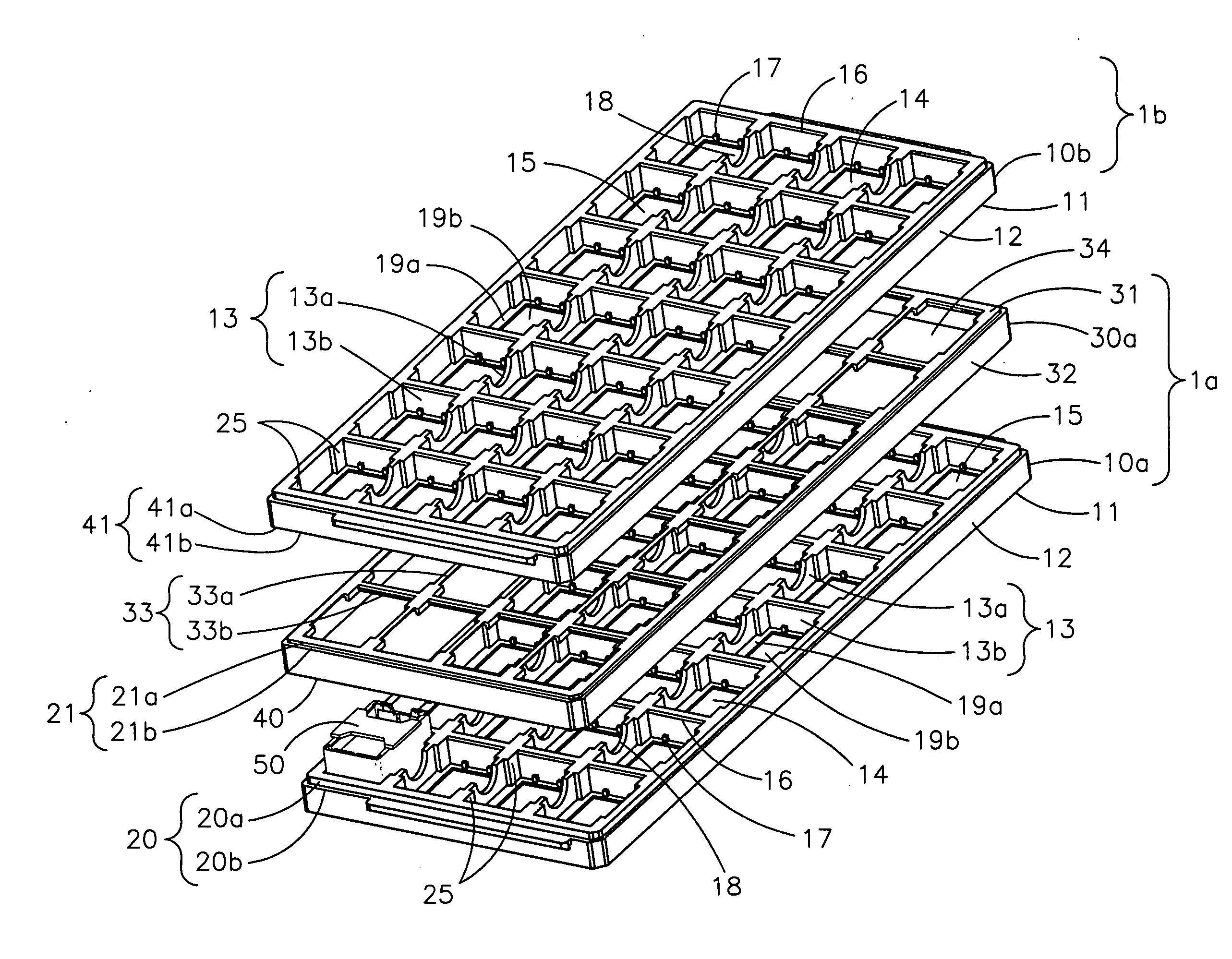

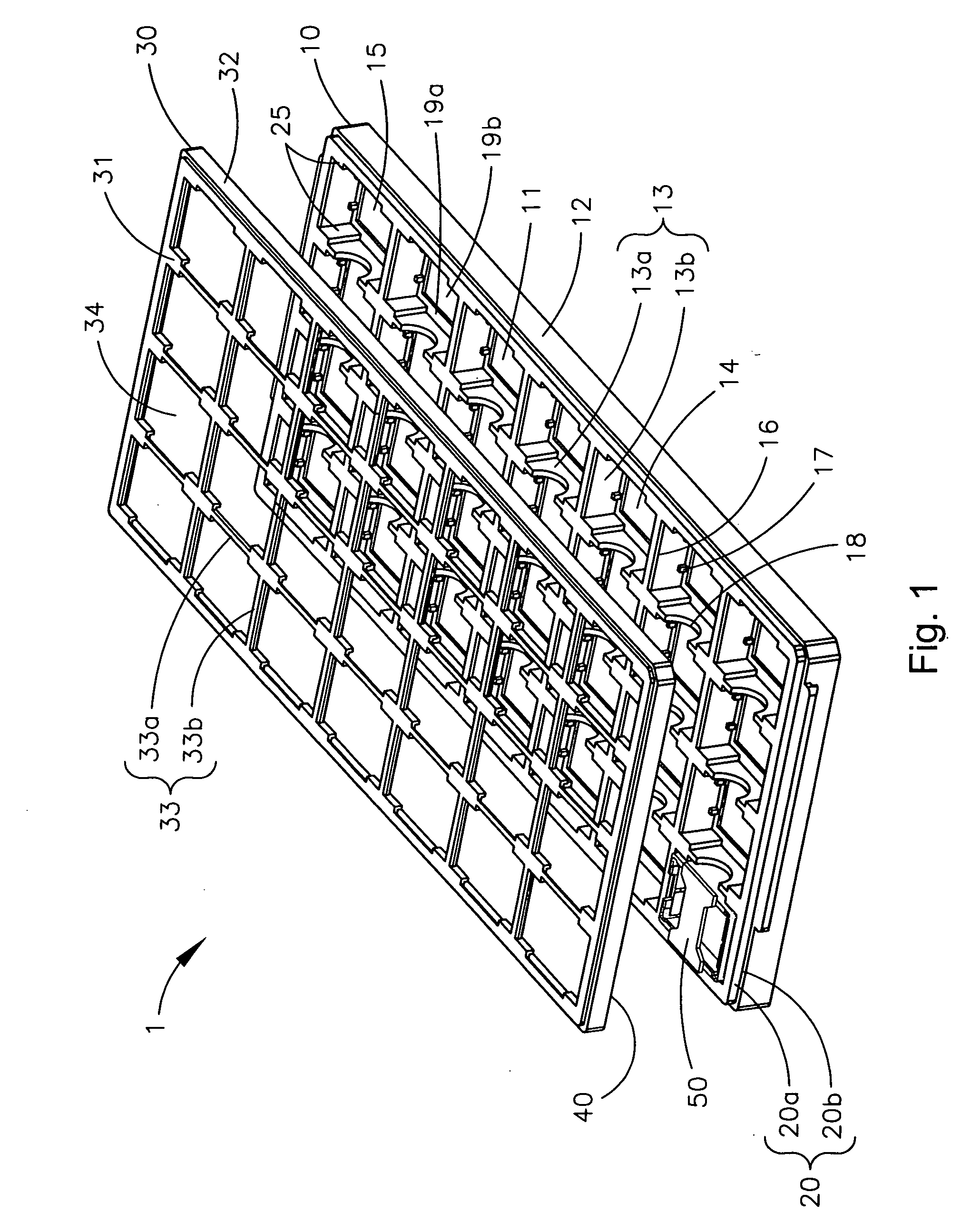

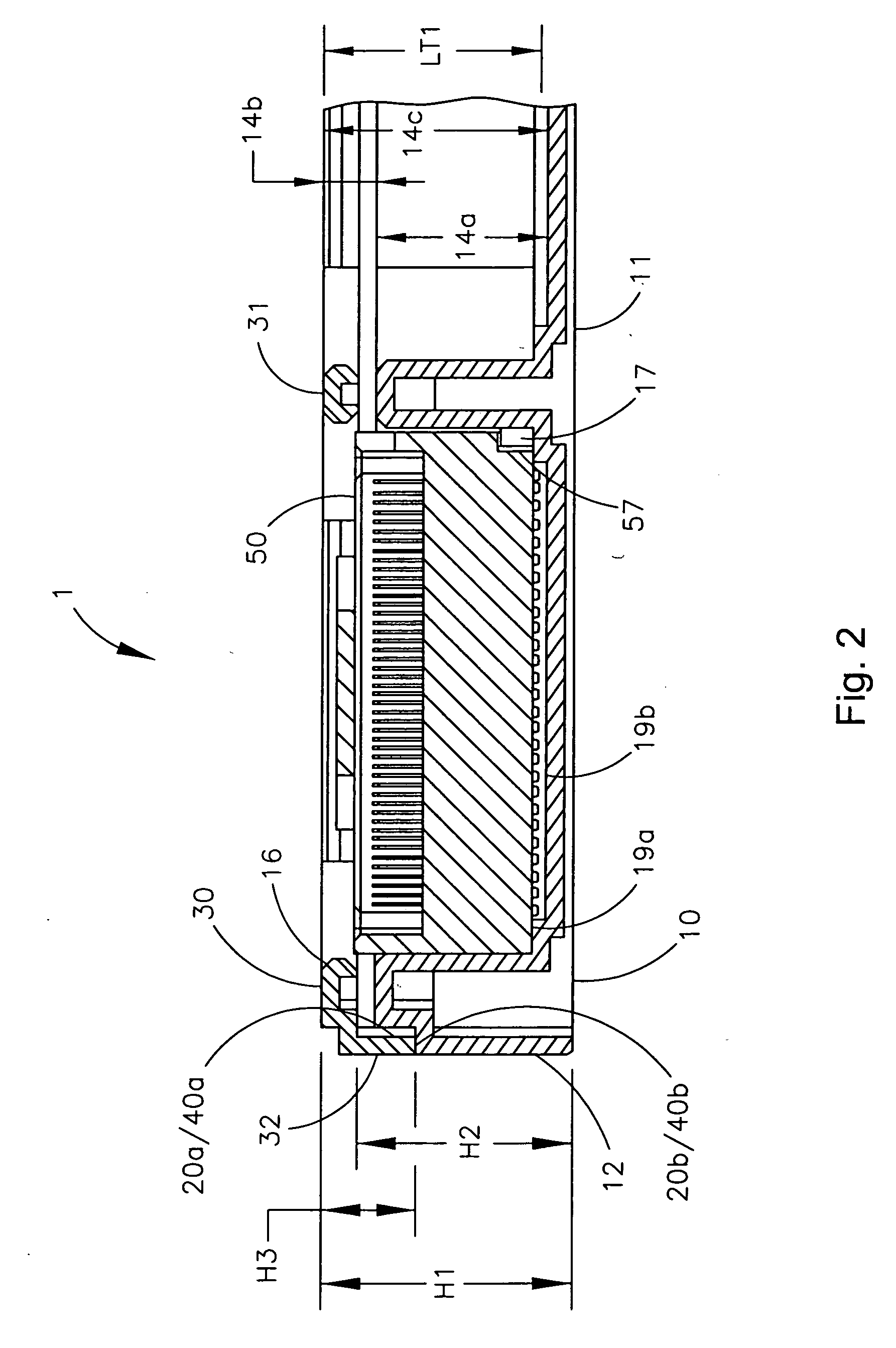

[0030] The present invention is directed to trays for component packaging. The packaging tray 1 may be constructed in multiple pieces to accommodate varying lift travel available to lift components 50 having different heights out of the packaging tray 1. This multiple part design makes it possible for handling and / or placement equipment 70 with limited available lift travel to operate by having a removable spacer tray 30 disposed over a base tray 10. The base tray 10 holds the component 50 and is designed and constructed to reduce and / or minimize the lift travel required to lift the component out of the base tray 10. The spacer tray 30 extends from the base tray 10 up and around the component 50 to protect the component 50 and to allow trays 1 to be stacked on top of one another.

[0031] This concept of a multi-piece packaging tray 1 applies to applications wherein lift travel available may be inadequate to lift the component from the tray 1. This concept of a multi-piece packaging t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com