Wet/dry utility vacuum and implement bag assembly

a technology of implement bag and wet/dry vacuum, which is applied in the direction of suction filter, cleaning filter means, suction cleaners, etc., can solve the problems of plurality of vacuum implements being separated from the wet/dry vacuum and misplaced, and storing structures are not well suited for use, so as to facilitate fluid drainage and convenient storage of plurality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

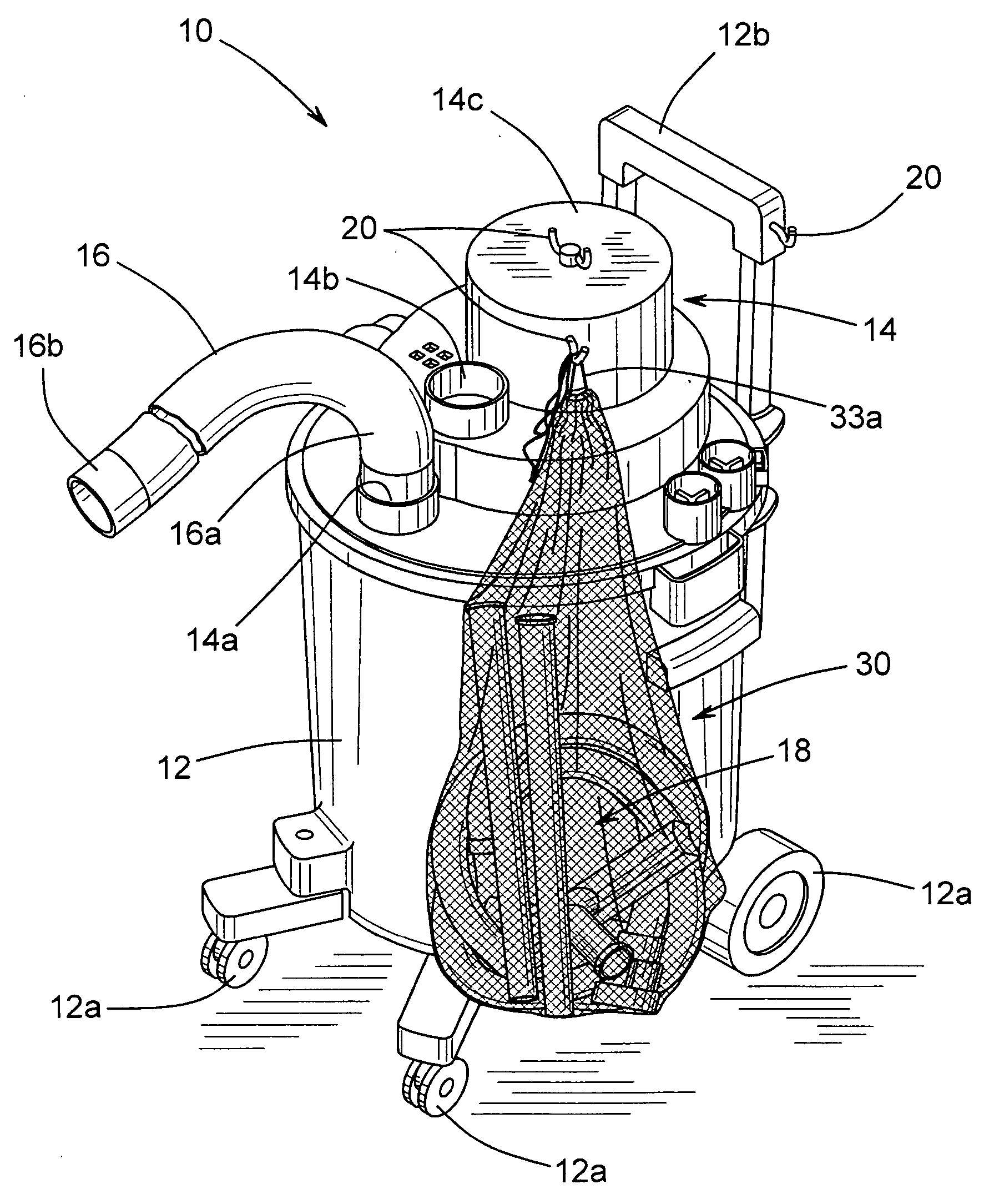

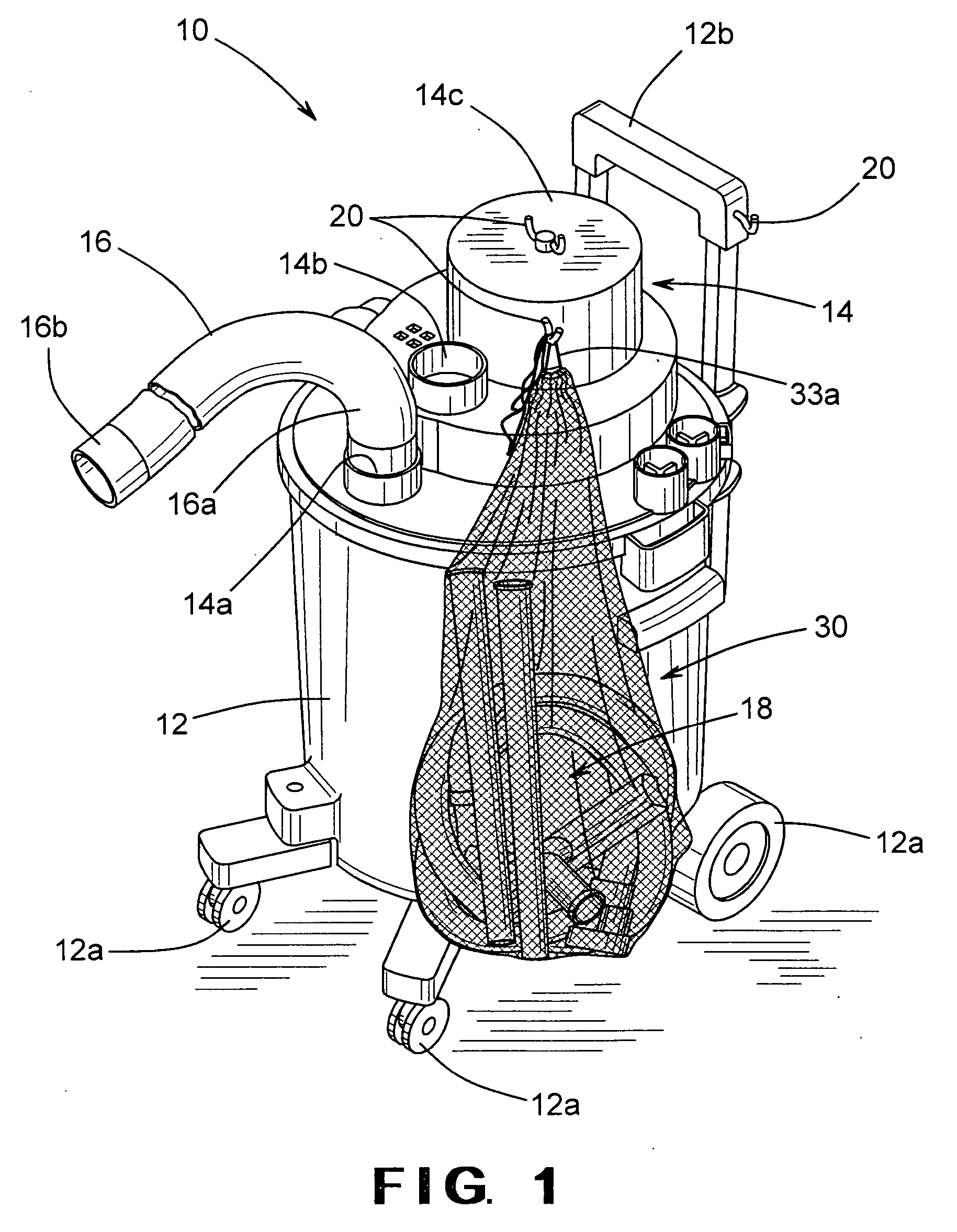

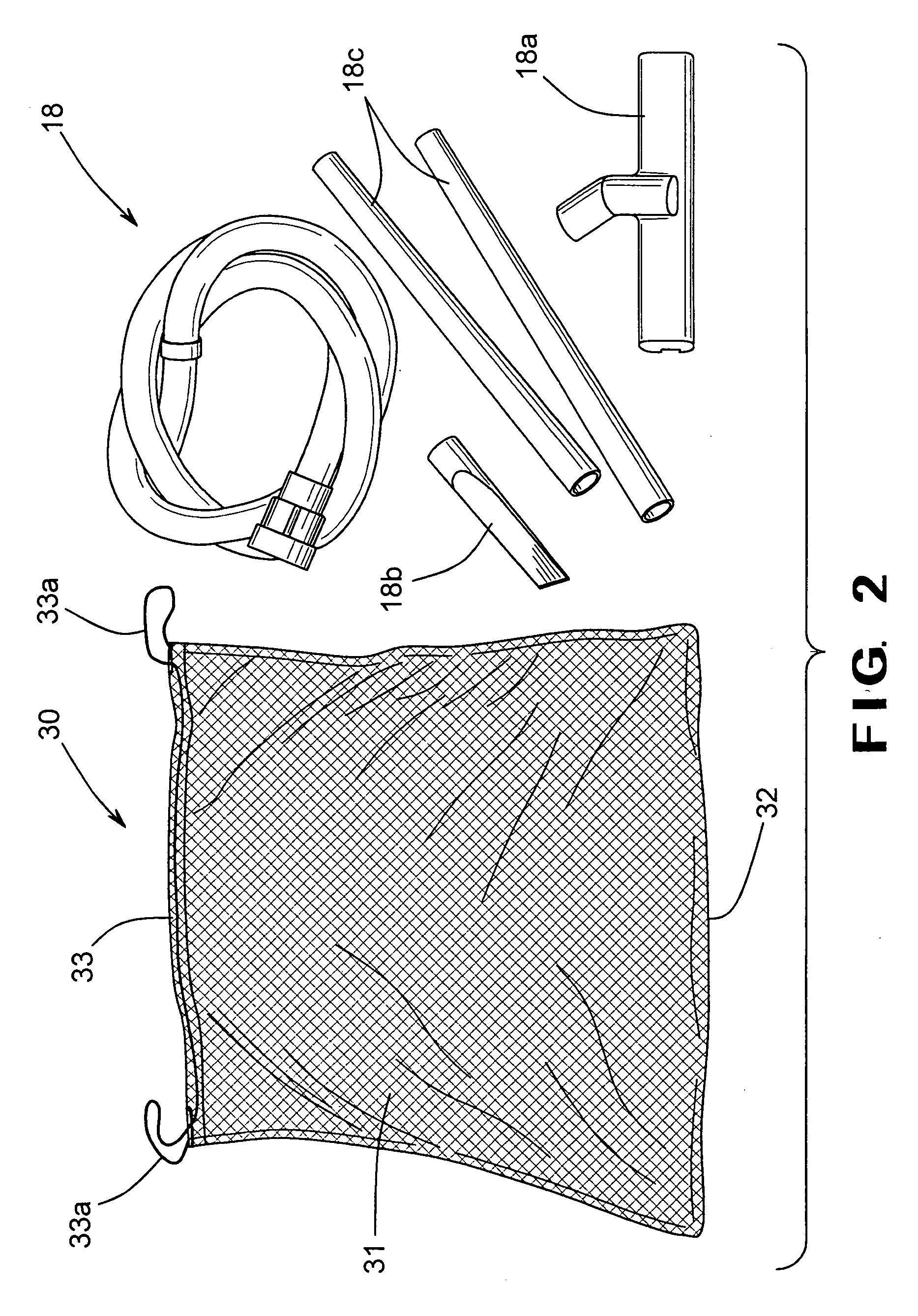

[0008] Referring now to the drawings, there is illustrated in FIG. 1 a wet / dry utility vacuum, indicated generally at 10, in accordance with this invention. The illustrated wet / dry utility vacuum 10, which is intended to be representative of any type of conventional wet / dry utility vacuum structure, includes a relatively large holding tank 12 having a closed bottom end, an opened upper end, and a hollow interior space. If desired, the bottom of the holding tank 12 may be supported on a plurality of wheels 12a to facilitate movement of the wet / dry utility vacuum 10 to and from a storage location and during use. An extendible handle 12b may be secured to the outside of the holding tank 12 to further facilitate movement of the wet / dry utility vacuum 10 to and from a storage location and during use.

[0009] A suction mechanism, indicated generally at 14, is supported on the opened upper end of the holding tank 12. The suction mechanism 14 is conventional in the art and includes an air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com