Mop with Foldaway Rod

a folding rod and mop technology, applied in the field of mop, can solve the problems of increasing the transporting cost accordingly, inconvenient storage, and poor cleaning results, so as to improve the strength of the screw pipe, reduce the transport volume and storage space, and improve the sturdiness of the mop in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

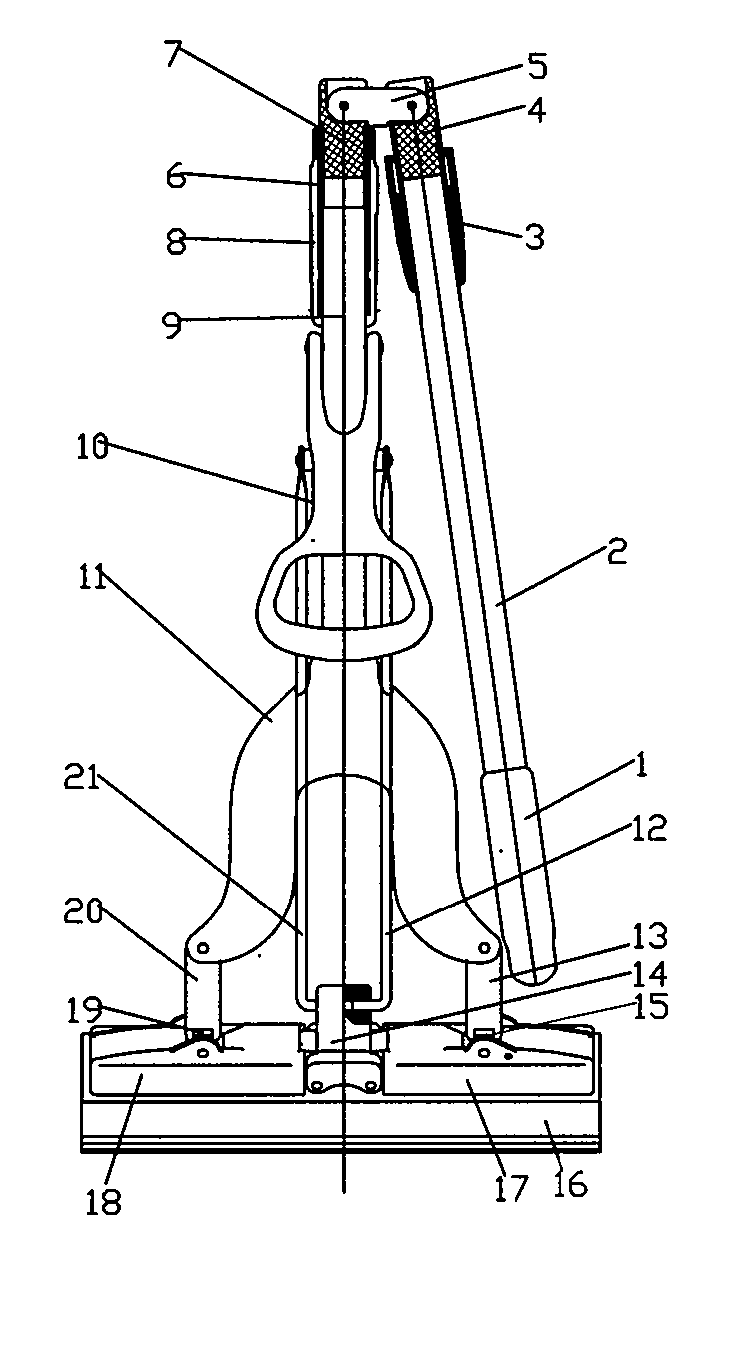

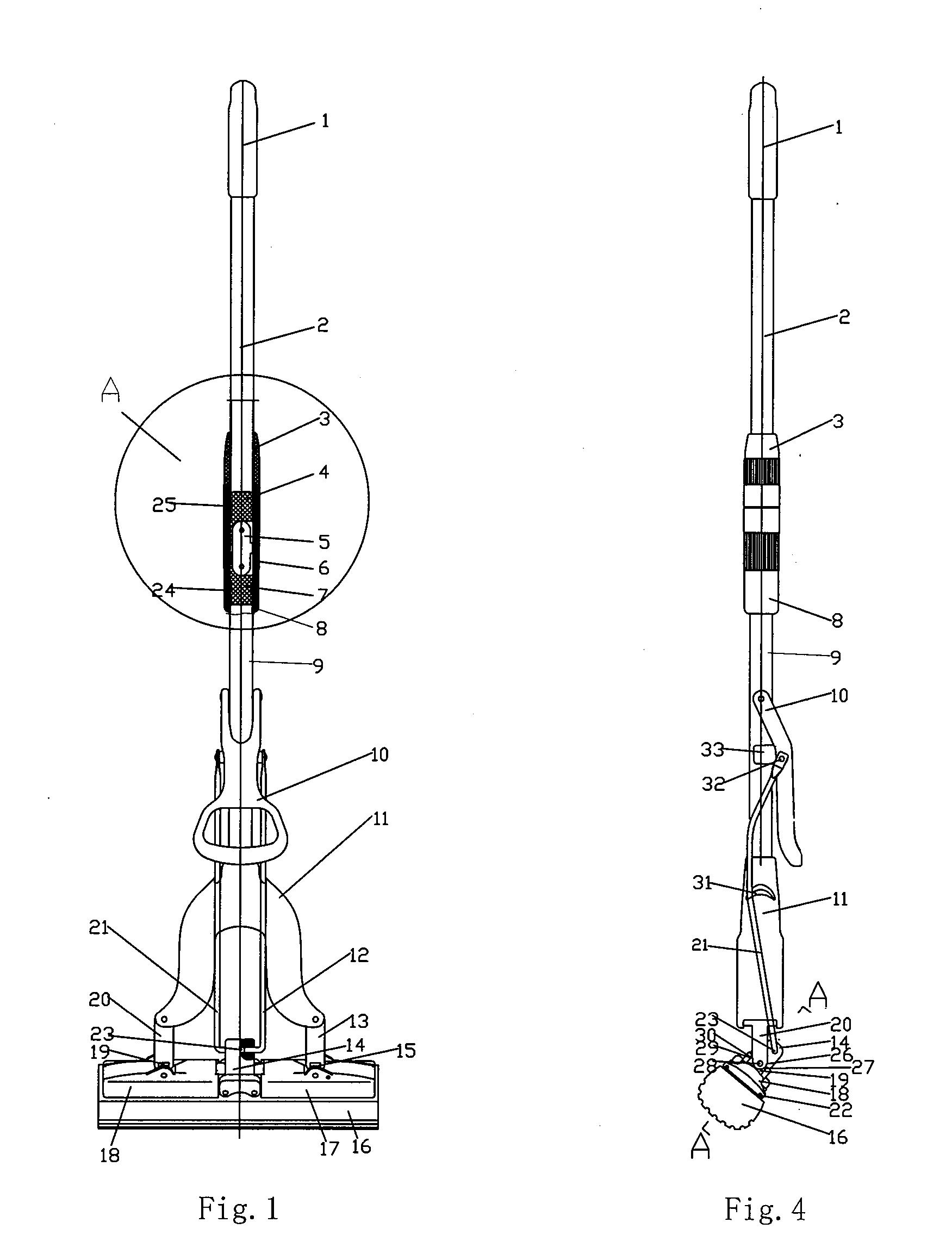

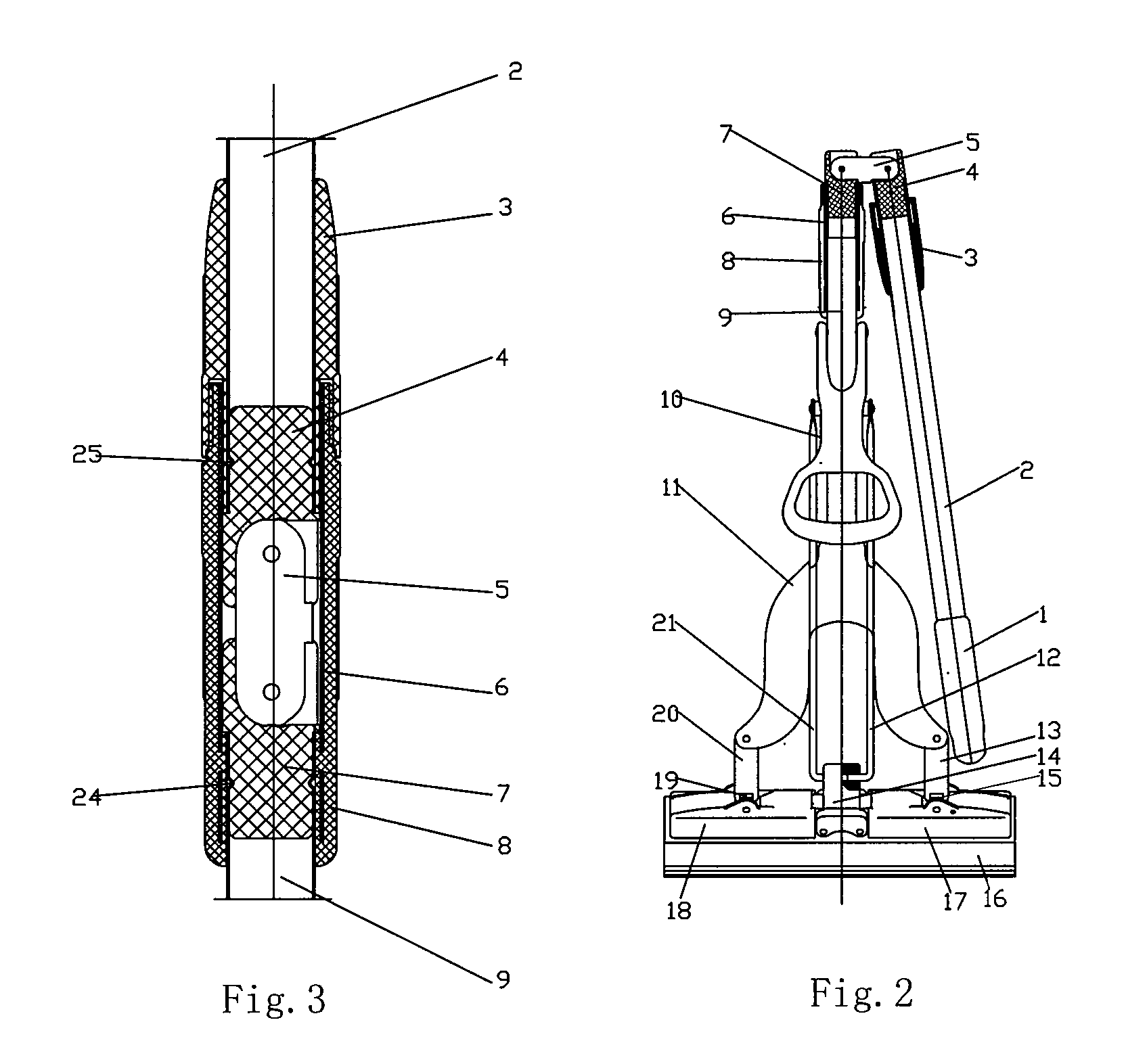

[0018] As shown in FIG. 1 and FIG. 2, a mop includes mop rod, water squeezing mechanism and mop head. Water squeezing mechanism includes hand grip 10, clamping holder base 11, left pull rod 21, right pull rod 12, left support rod 20, right support rod 13, connecting block 14, universal base 15, 19, left base plate 18 and right base plate 17. The mop rod includes upper rod portion, folding mechanism and lower rod 9. Upper rod portion includes upper hand grip 1 and upper rod 2, upper hand grip 1 is riveted onto the upper end of upper rod 2. As shown in FIG. 3, folding mechanism includes screw sleeve 3, upper joint 4, connecting rod 5, casing pipe 6, lower joint 7 and screw pipe 8. Screw sleeve 3 is encased into the bottom of upper rod 2, with which to form tight connection. Upper joint 4 is inserted into the casing at the lower end of upper rod 2, and is firmly connected with upper rod 2 by point riveting. Screw pipe 8 is encased into upper end of the lower rod 9 to form slide fit wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com