Splicing and connectorization of photonic crystal fibers

a technology of photonic crystal fibers and connectors, applied in the field of optical fibers, can solve the problems of poor mechanical strength, high splice loss, and difficult transition from small core pcfs to standard optical fibers, and achieve the effect of low loss and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0159] In order to explain the invention in more detail, the proceeding description shall be based on examples. The examples illustrate the concepts and design ideas that underlie the invention. It is to be understood that the examples are merely illustrative of the many possible specific embodiments which can be devised from the present invention as well as there exists many possible applications that may be devised from the principles of the invention. The presented examples are not intended to limit the scope of the invention.

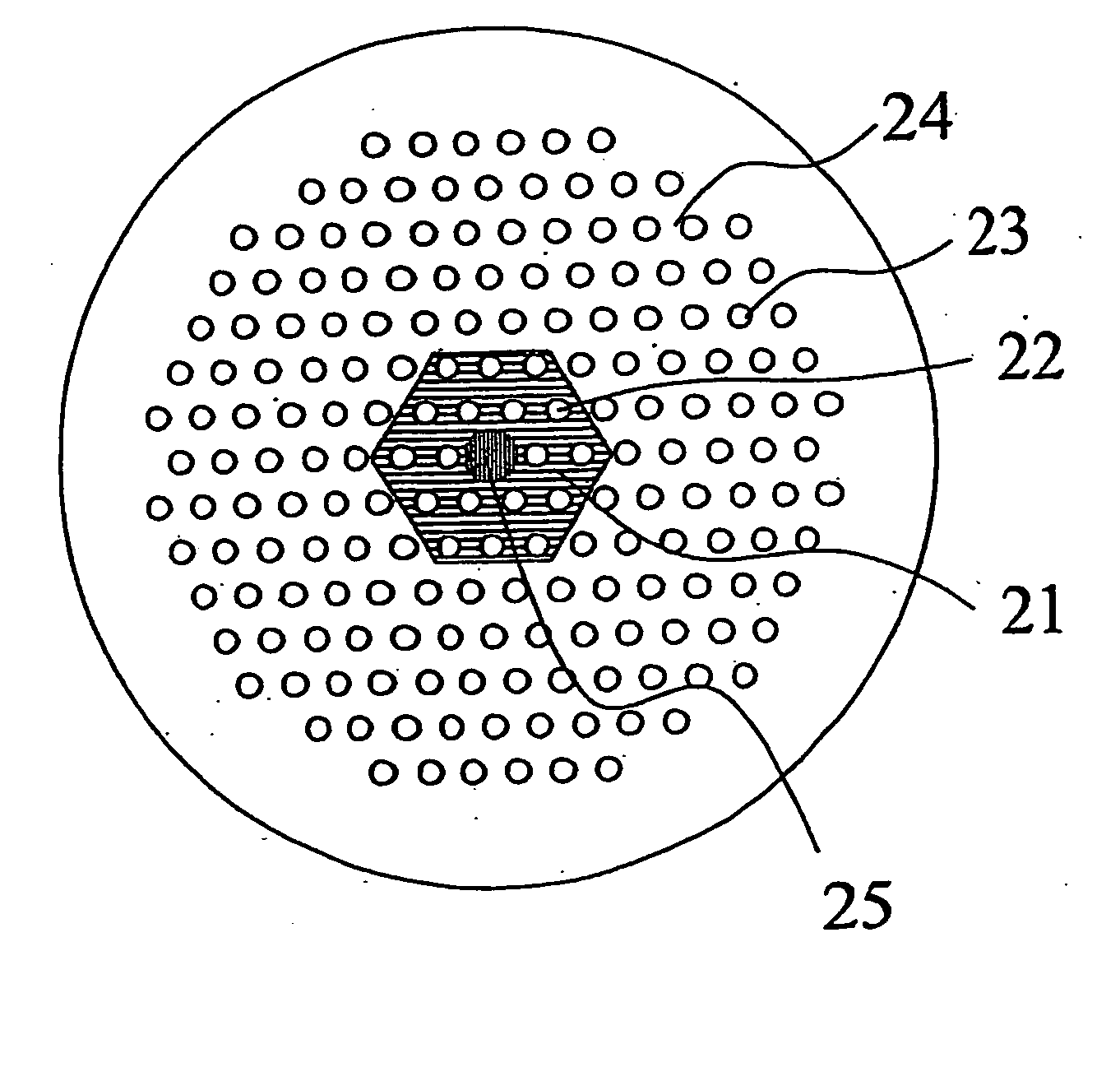

[0160] The present invention discloses in a preferred embodiment a spliceable optical fibre, of which a cross sectional view perpendicular to a longitudinal direction of the fibre is shown schematically in FIG. 1. The fibre is a photonic crystal fibre comprising a core region 10 and a cladding region, the cladding region comprising an inner cladding region 11 and an outer cladding region 12. The inner cladding region comprises low-index inner cladding featu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com