Vibration damping unit

a technology of vibration damping and damping unit, which is applied in the direction of shock absorbers, mechanical equipment, and support structure mounting, etc., can solve the problems of workers being released from troublesome works, and achieve the effect of preventing the sway of an existing rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

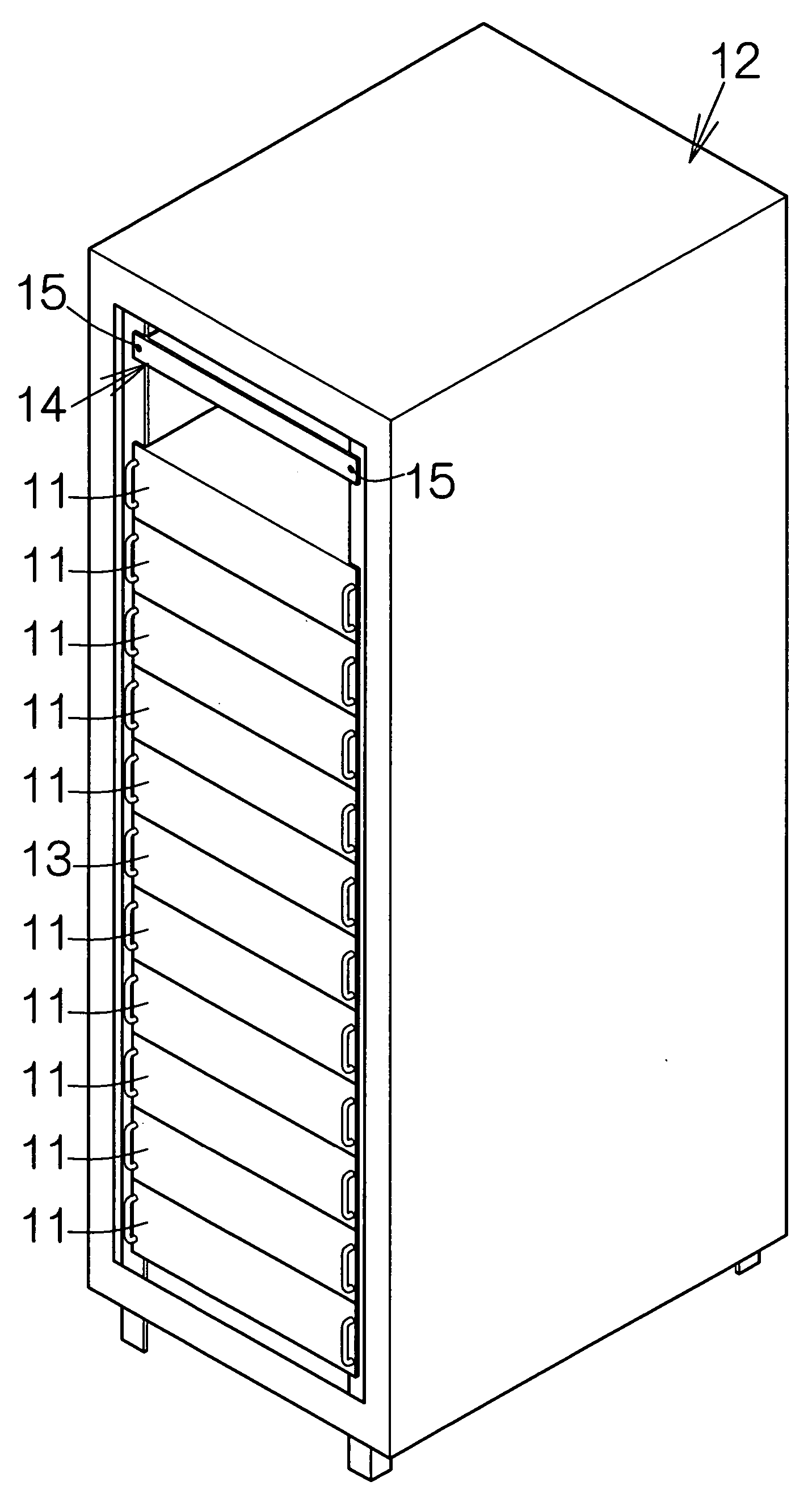

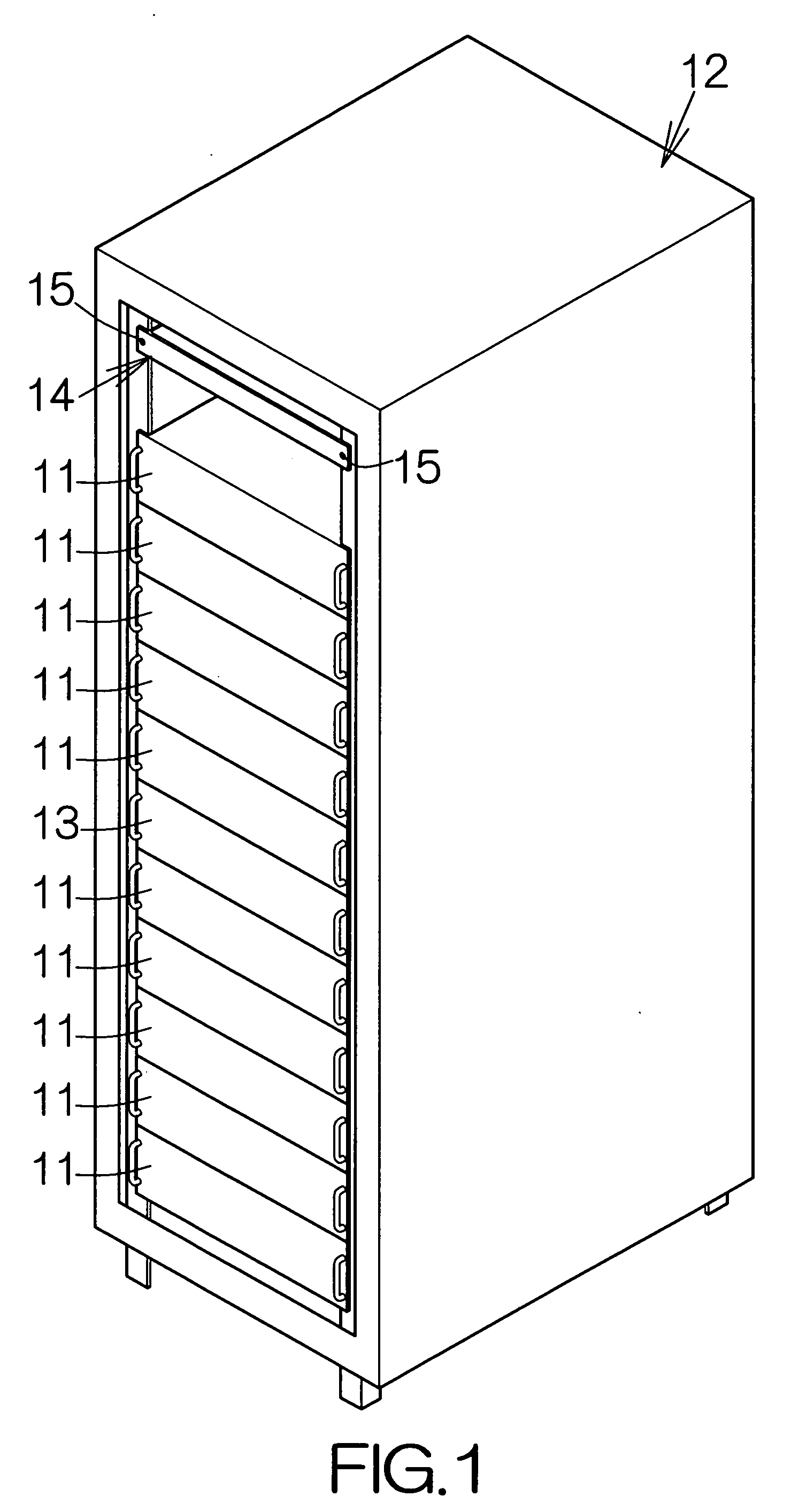

[0024]FIG. 1 schematically illustrates a rack 12 containing a rack-mounted disk array apparatus. In this case, a plurality of disk array apparatuses 11 are mounted on the rack 12, for example. The disk array apparatuses 11 are connected to a host or server computer 13 likewise mounted on the rack 12, for example. The disk array apparatuses 11 operate in response to instruction signals supplied from the server computer 13.

[0025] As conventionally known, recording disk drives or hard disk drives (HDDs) are mounted in the individual disk array apparatus 11. The hard disk drive may include a recording disk or hard disk (HD) having the rotation axis extending in the vertical direction perpendicular to the floor, for example. In this case, each disk array apparatus 11 holds fifteen hard disk drives. Alternatively, the rotation axis of the hard disk may extend in the horizontal direction in parallel with the floor.

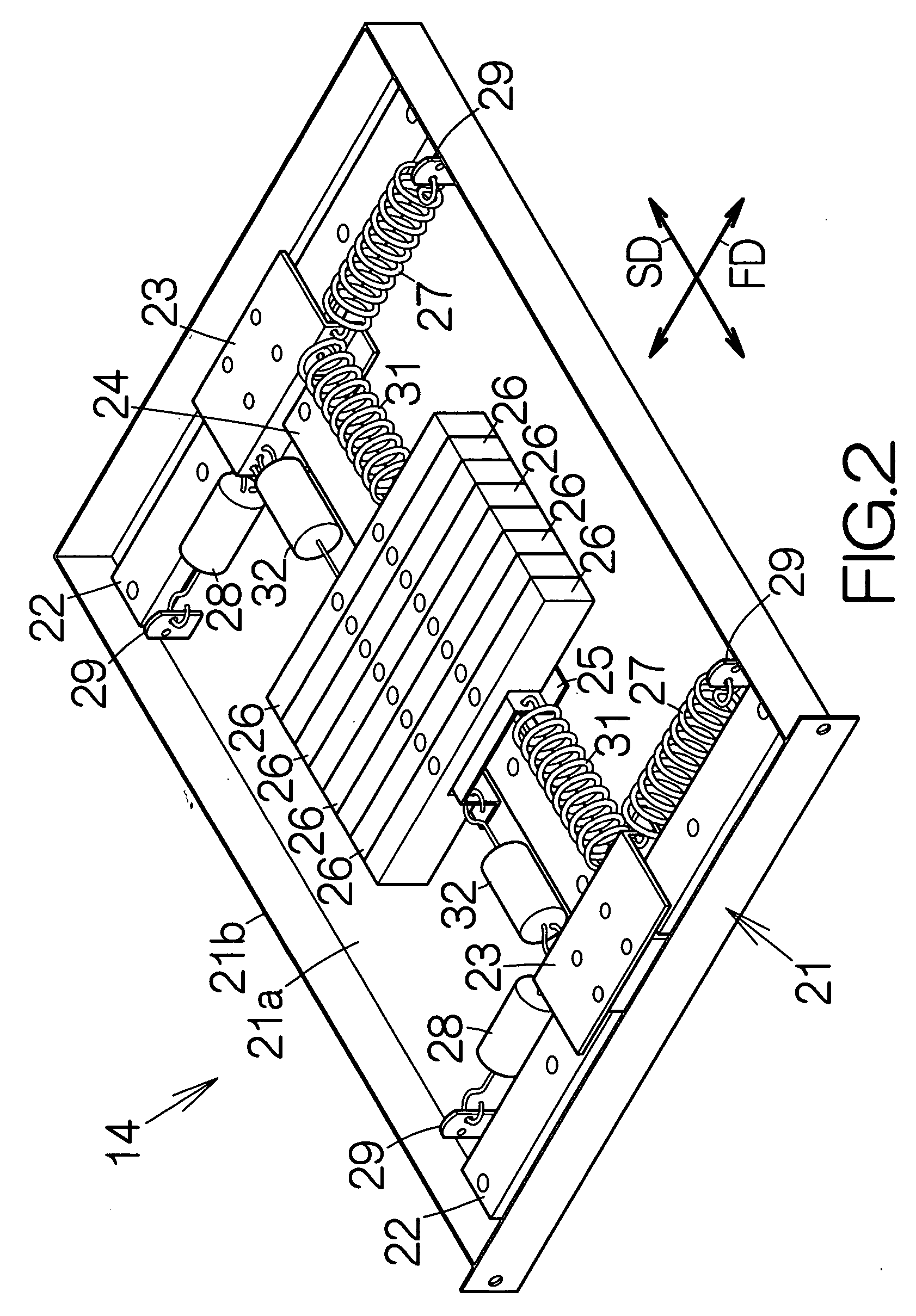

[0026] A vibration damping unit 14 is mounted on the rack 12 just below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com