Shelf shipping clip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

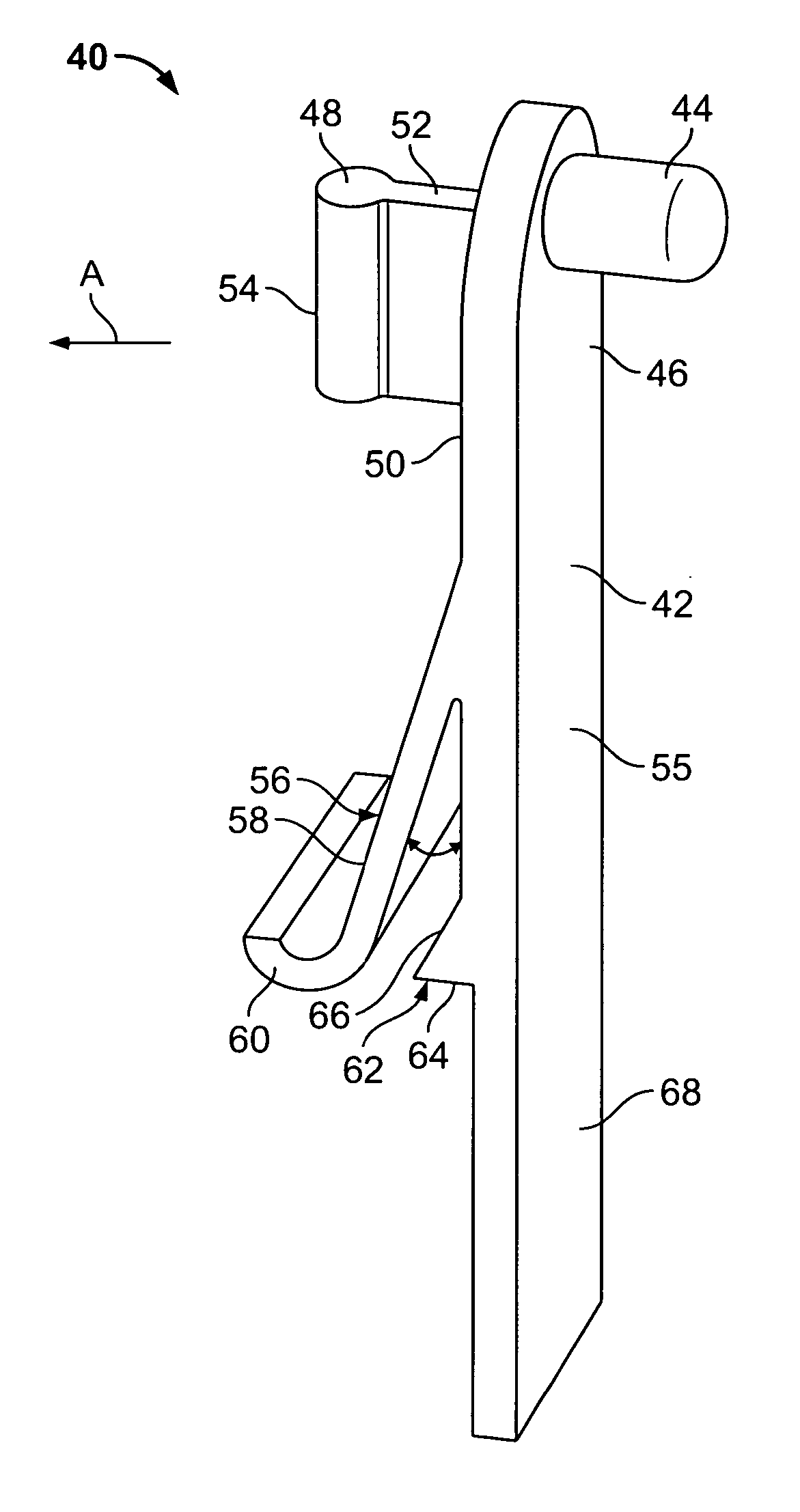

[0024]FIG. 5 illustrates an isometric view of a shipping clip 40 according to an embodiment of the present invention. The shipping clip 40 may be formed of various materials, such as rubber, or plastic. The shipping clip 40 includes a main beam 42 having a cabinet securing post 44 extending from a wall-abutting side 46. The cabinet securing post 44 is configured to be retained within a securing hole (not shown in FIG. 5) within a cabinet wall (not shown in FIG. 5).

[0025] A handle 48 extends from a shelf side 50 (which is opposite the wall-abutting side), and proximate the top of the main beam 42. That is, the handle 48 and the post 44 extend from opposite sides 50 and 46, respectively, of an upper portion of the main beam 42. The handle 48 may include a vertical fin 52 extending outwardly from the side 50. The vertical fin 52 may be integrally formed with a cylindrical post 54. The vertical fin 52 and the cylindrical post 54 may be ergonomically configured to allow easy grasping of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com