Channel system for factory built structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

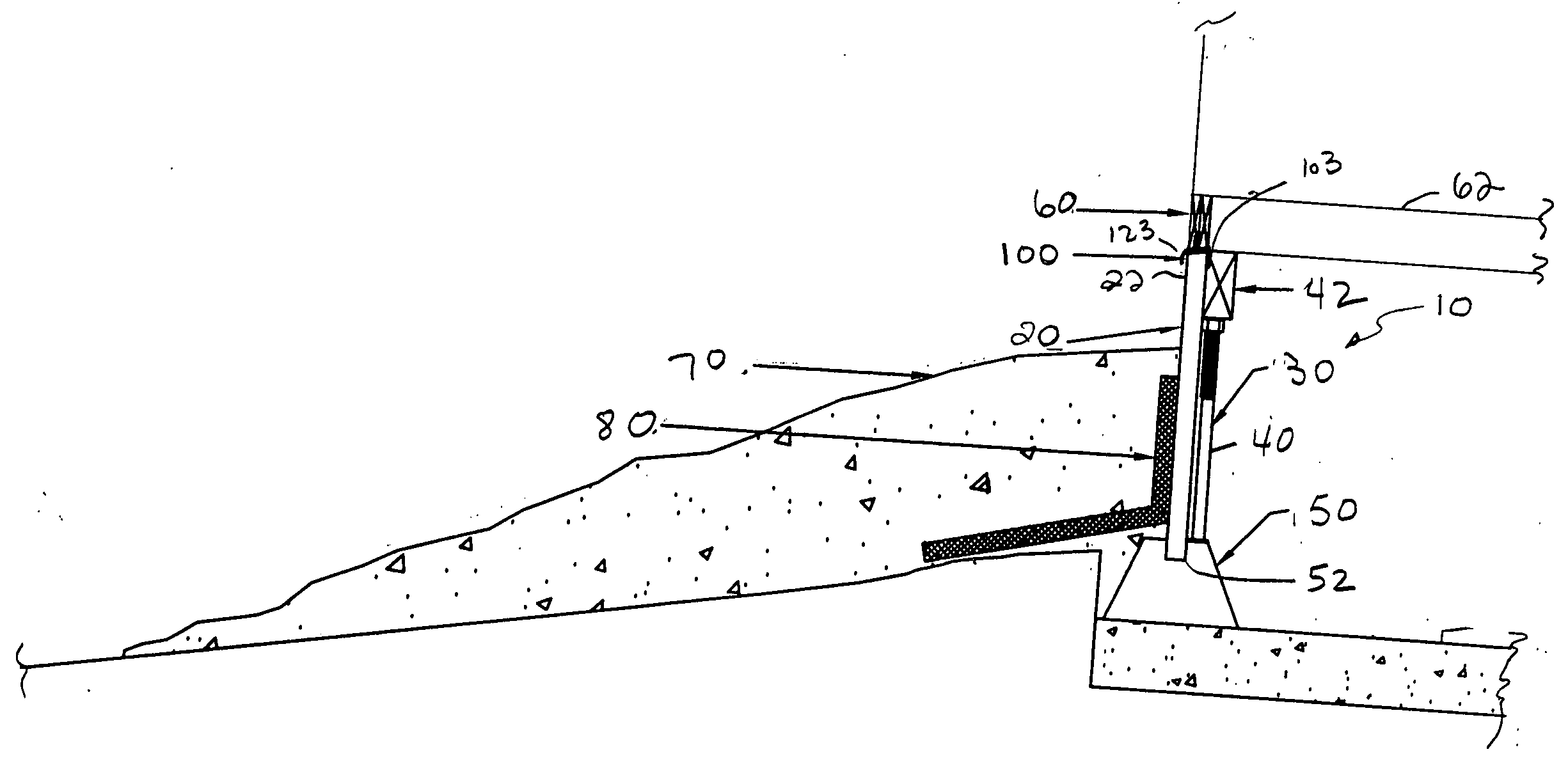

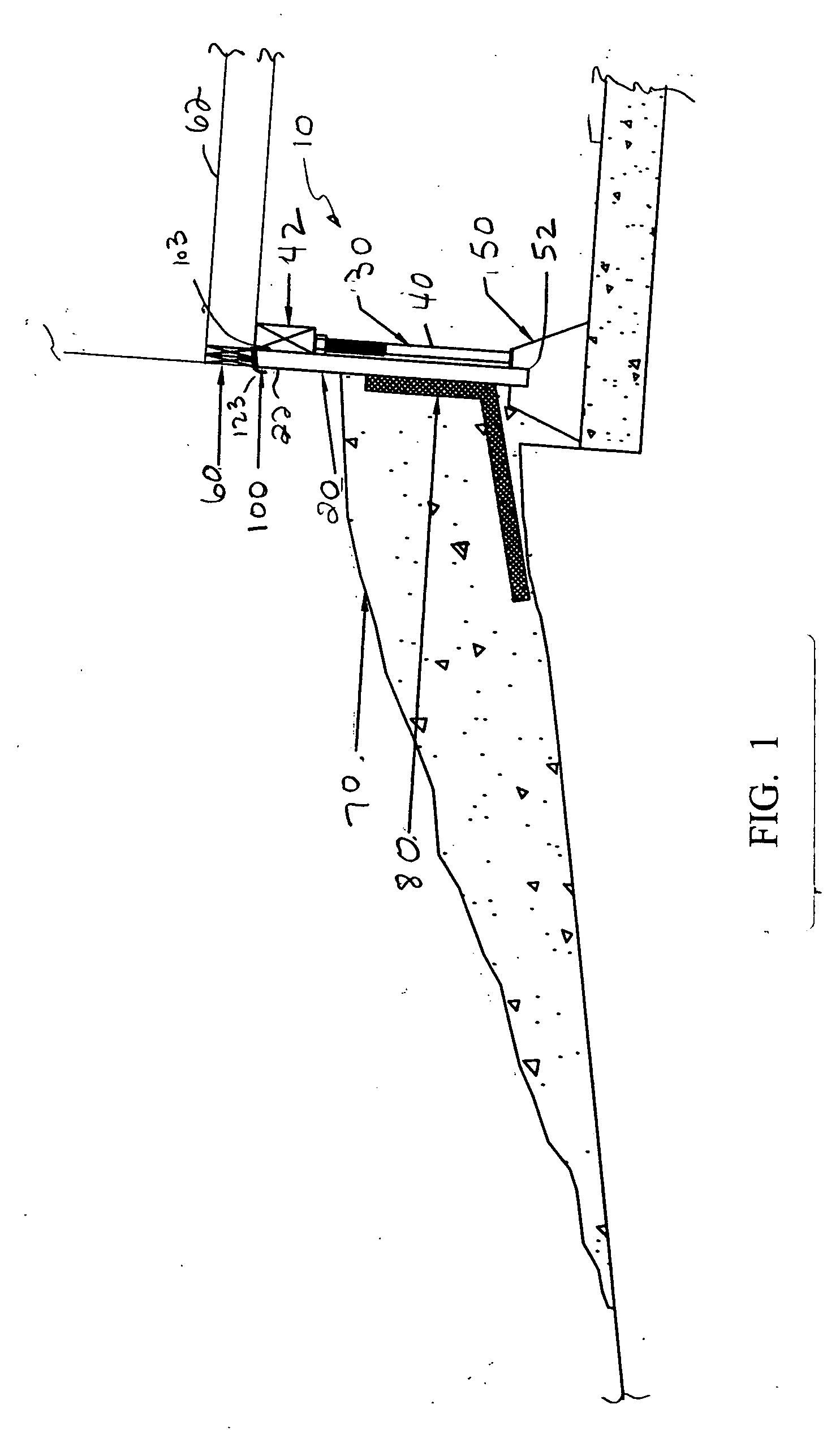

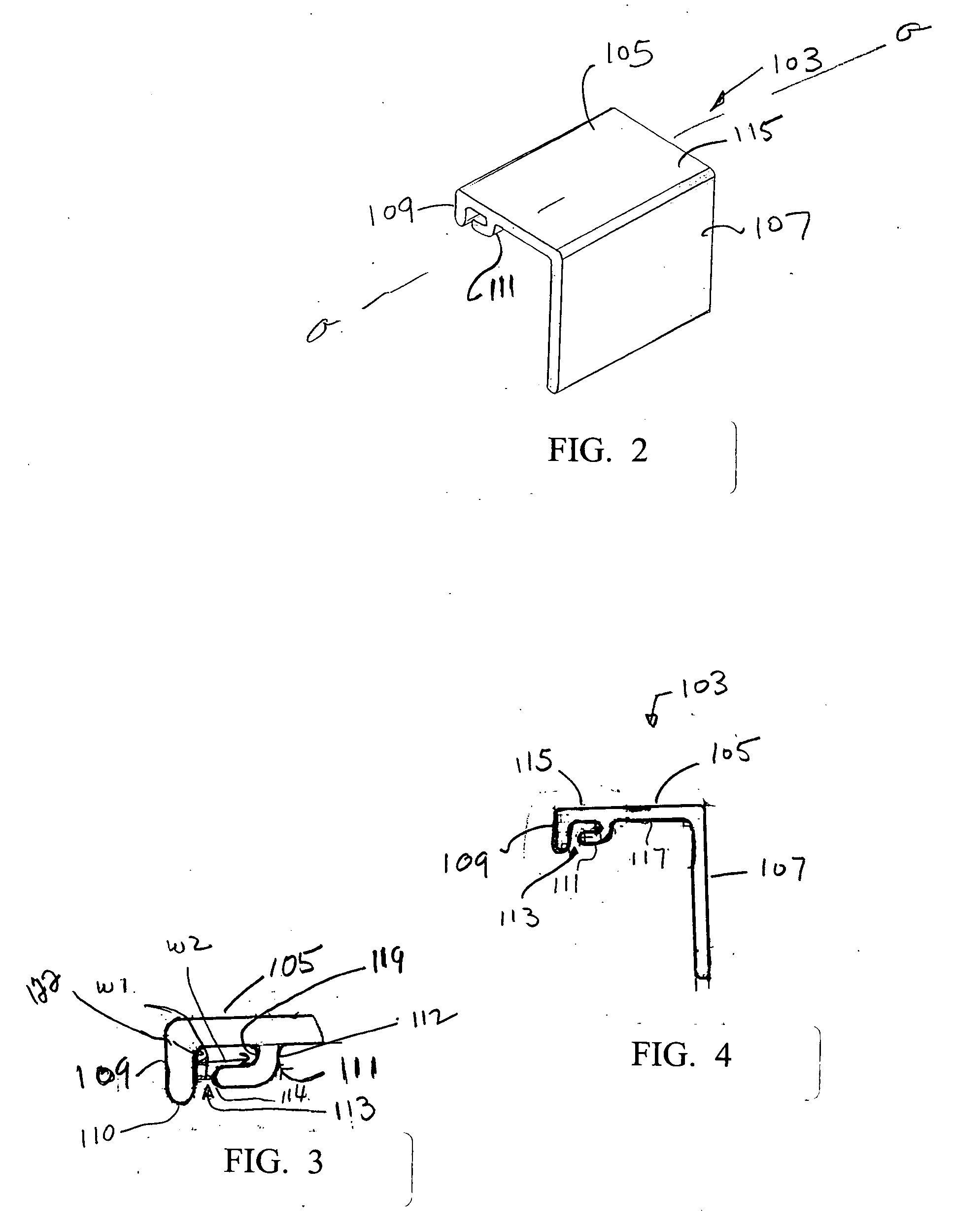

[0021]FIG. 1 illustrates a skirting and support system 10 for factory built buildings that employ a channel system 100 according to the teaching of the present invention. For ease of explanation, the discussion will relate to two types of factory built buildings, manufactured homes and modular homes. Nevertheless, the application of the skirting and support system 10 and / or the channel system 100 can be used with other types of factory built buildings.

[0022] In one example, the skirting and support system 10 comprises a perimeter skirting assembly 20 and a support assembly 30. The support assembly 30 includes at least one support stand 40 and at least one perimeter load bearing footing 50. A wooden block 42 is provided to the top of the support stand 40 in order to carry the load of two to three floor joists 62 of the factory built structure. The skirting assembly 20 includes at least one elongated skirting panel 22. Footing 50 has an elongated slot 52 which extends along the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com