Container opening structure, container provide with the opening structure and method of manufacturing the opening structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

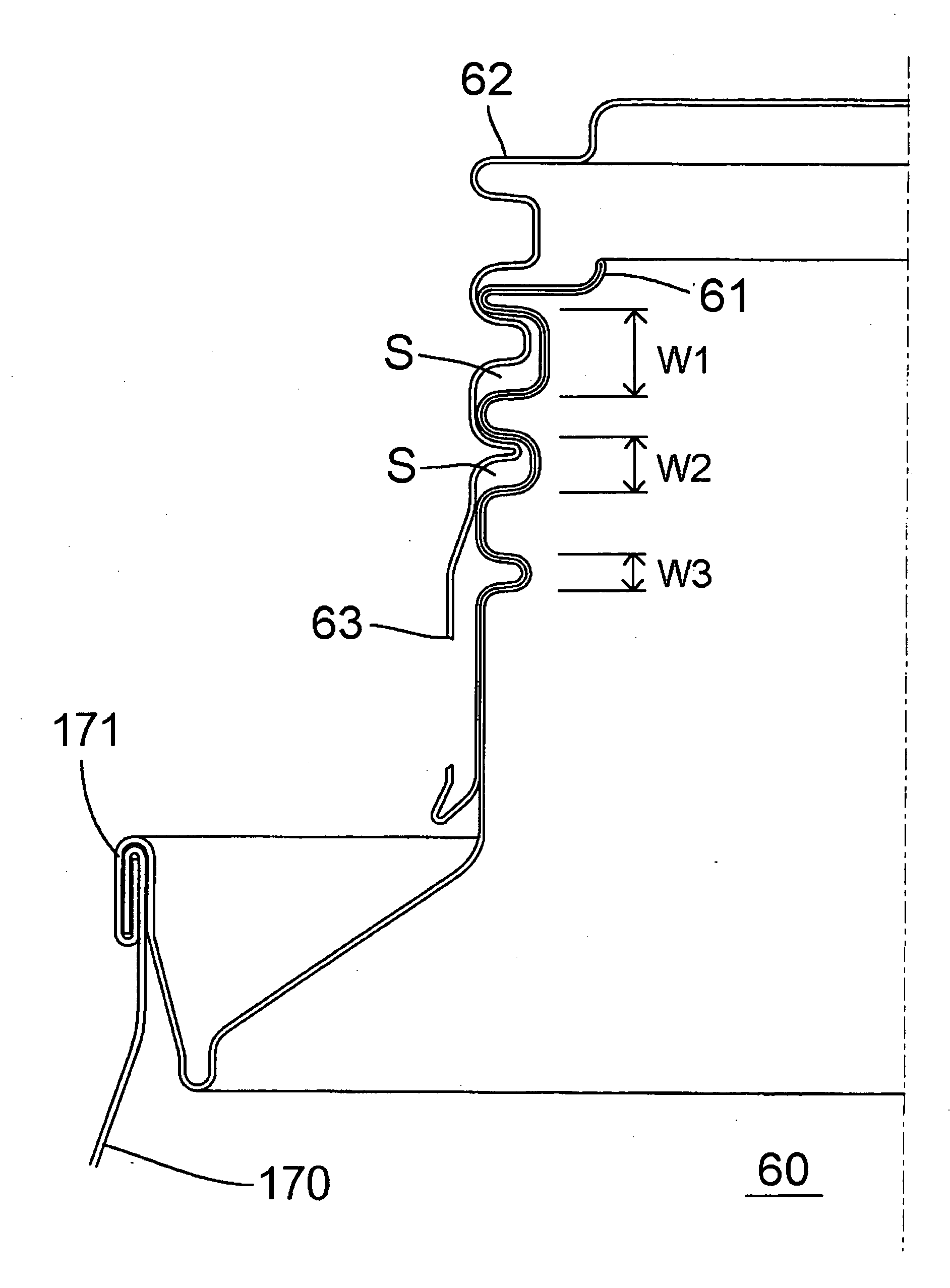

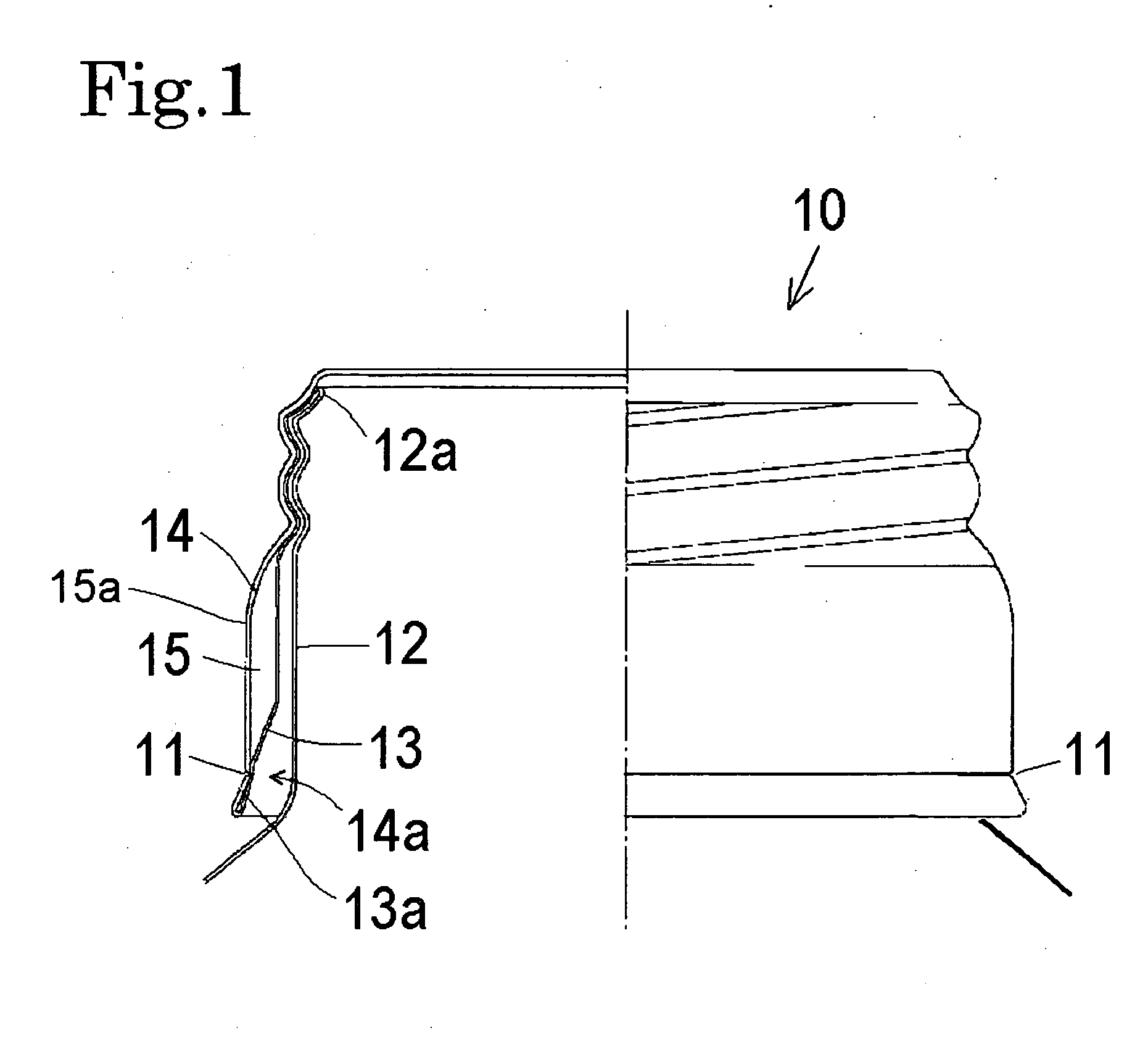

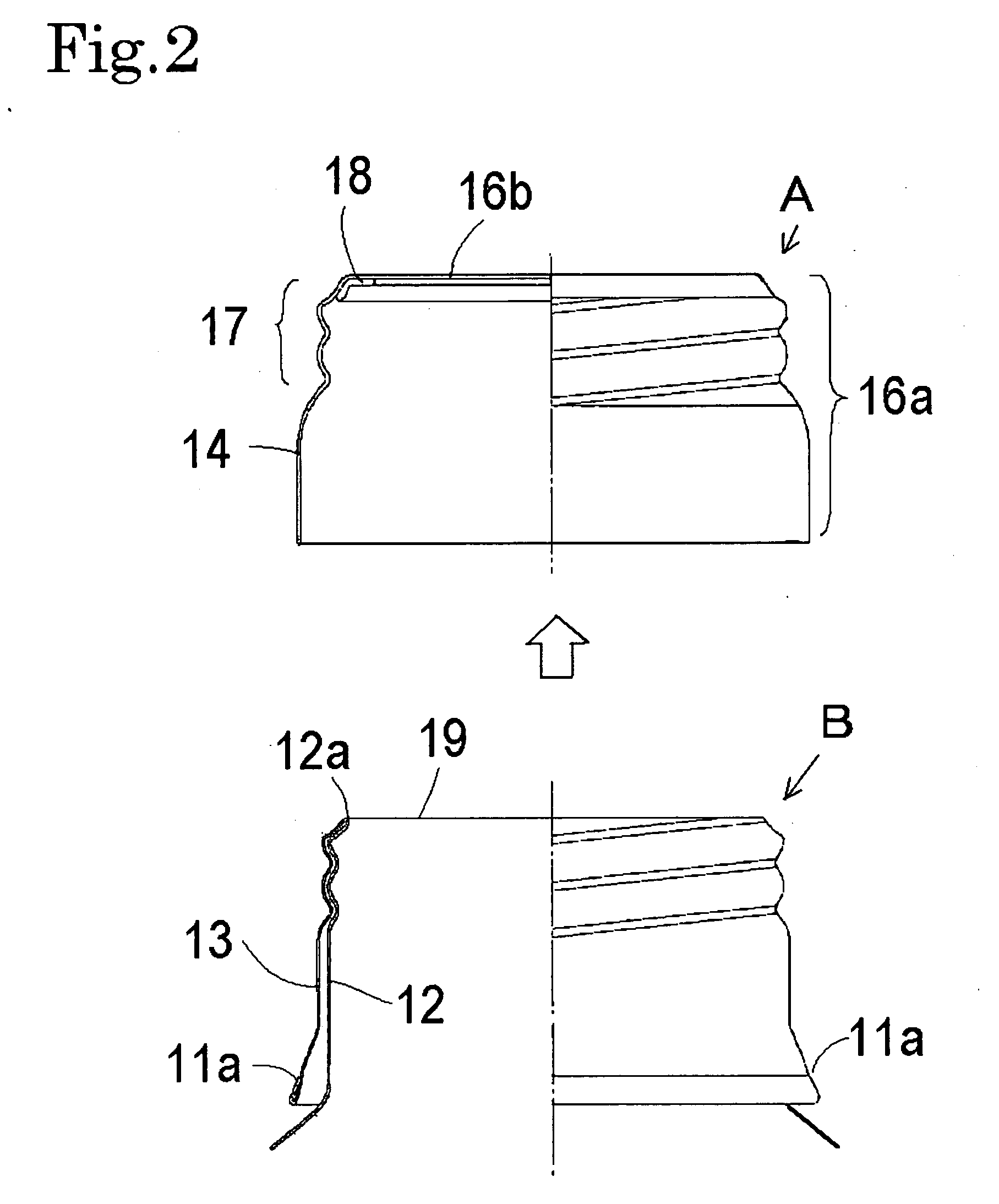

[0130]FIG. 1 is a cross-sectional view of an essential part of the opening structure of the container of an embodiment 1 of the present invention. FIG. 2 is an explanatory view showing a state in which a cap portion of the opening structure of the container is removed. As shown in FIG. 1 and FIG. 2, the opening structure 10 of the container of the embodiment 1 of the present invention is characterized in that, in the opening structure of the container in which a cap portion A and a pouring portion B are continuously and integrally formed, due to a radial deformation of an easy-to-break portion 11 which is present in a boundary between the cap portion A and the pouring portion B, the easy-to-break portion 11 is broken so as to separate the cap portion A and the pouring portion B whereby the container is opened.

[0131] In the opening structure 10 of the container of the embodiment 1 of the present invention, the cap portion A and the pouring portion B are continuously and integrally f...

embodiment 2

[0150]FIG. 4 is a cross-sectional view of an essential part of an opening structure of a container of an embodiment 2 of the present invention. In the opening structure 20 of a container of the embodiment 2, an easy-to-break portion 21 is formed on a lower portion 24b of an outer wall 24 and the lower-end close-contact portion 14a between the outer wall 14 and the intermediate wall 13 which is provided in the above-mentioned embodiment 1 is not formed. With respect to other constitutional points including a point that a deflection deformation portion 25 is provided in a gap defined between the outer wall 24 and an intermediate wall 23, this embodiment is substantially equal to the embodiment 1 of the present invention.

embodiment 3

[0151]FIG. 5 is a cross-sectional view of an essential part of a container which includes an opening structure of a container of an embodiment 3 of the present invention. In the opening structure 30 of a container of the embodiment 3, an outer wall 34 and an intermediate wall 33 are continuously connected over whole portions ranging from upper ends to lower ends thereof, and an easy-to-break portion 31 is formed in a lower portion 34b of the outer wall 34. Further, a deflection deformation portion 35 is provided in a space defined between an inner wall 32 and the intermediate wall 33. With respect to other constitutional points, the embodiment 3 is substantially equal to the embodiment 1 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com