Disposal Bag Assembly And Disposal System

a technology of disposal bag and disposal bag, which is applied in the field of sanitary napkin disposal bin, can solve the problems of hazardous activities for maintenance personnel, soiling the bin, and the removal of a bag filled with refuse, so as to improve the system in use, enhance the operation of the system, and improve the effect of the disposal bag system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

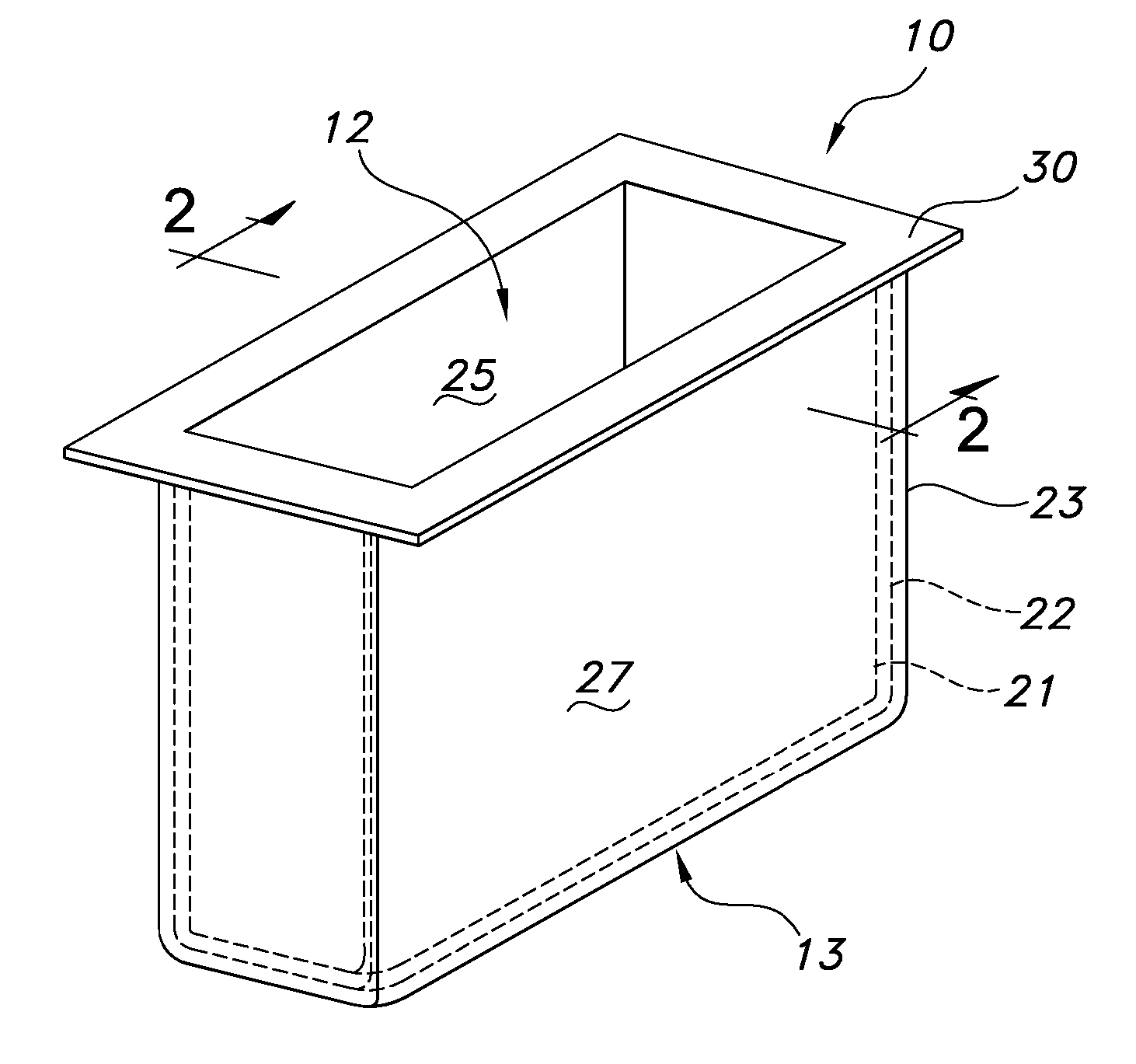

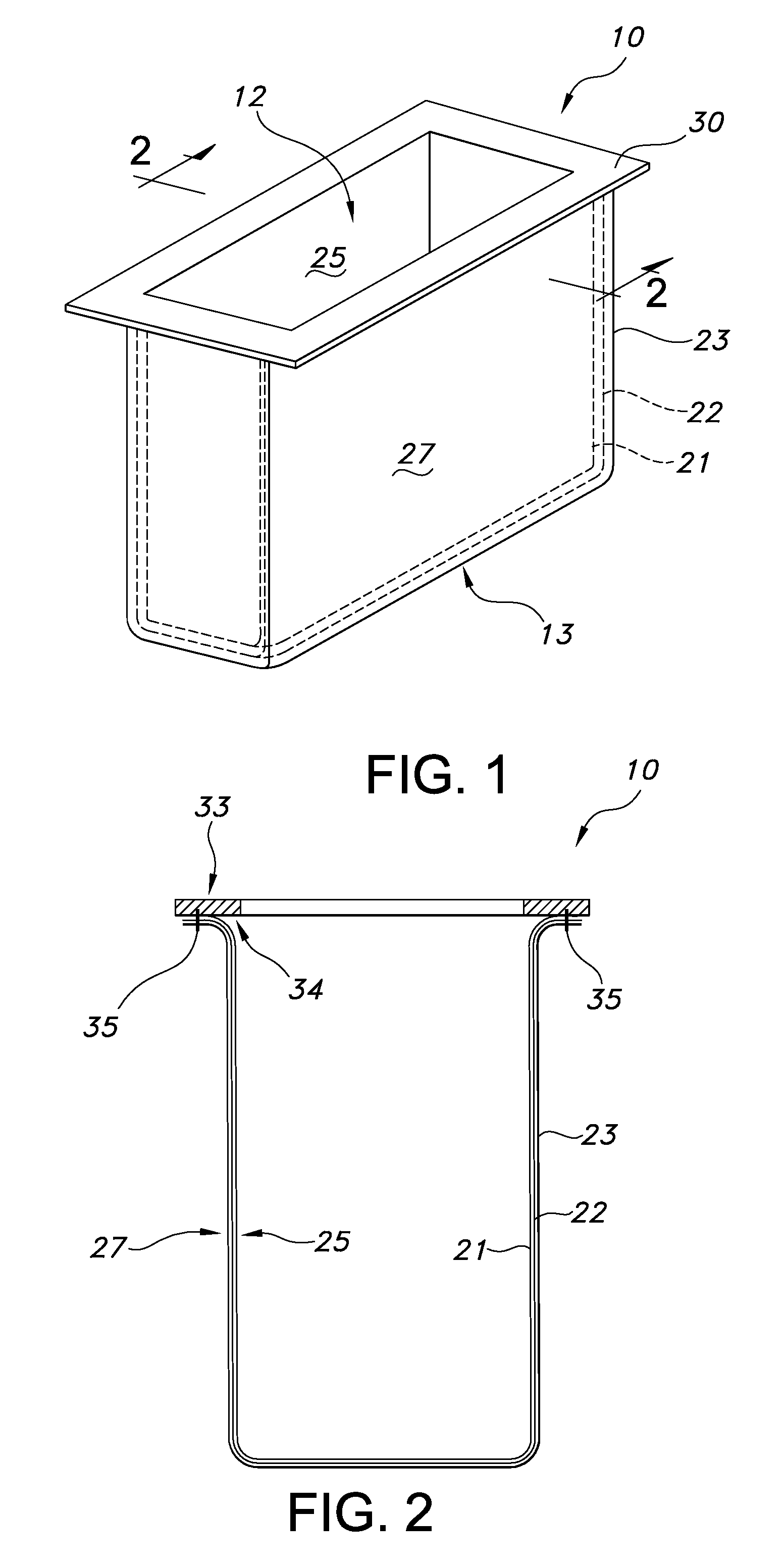

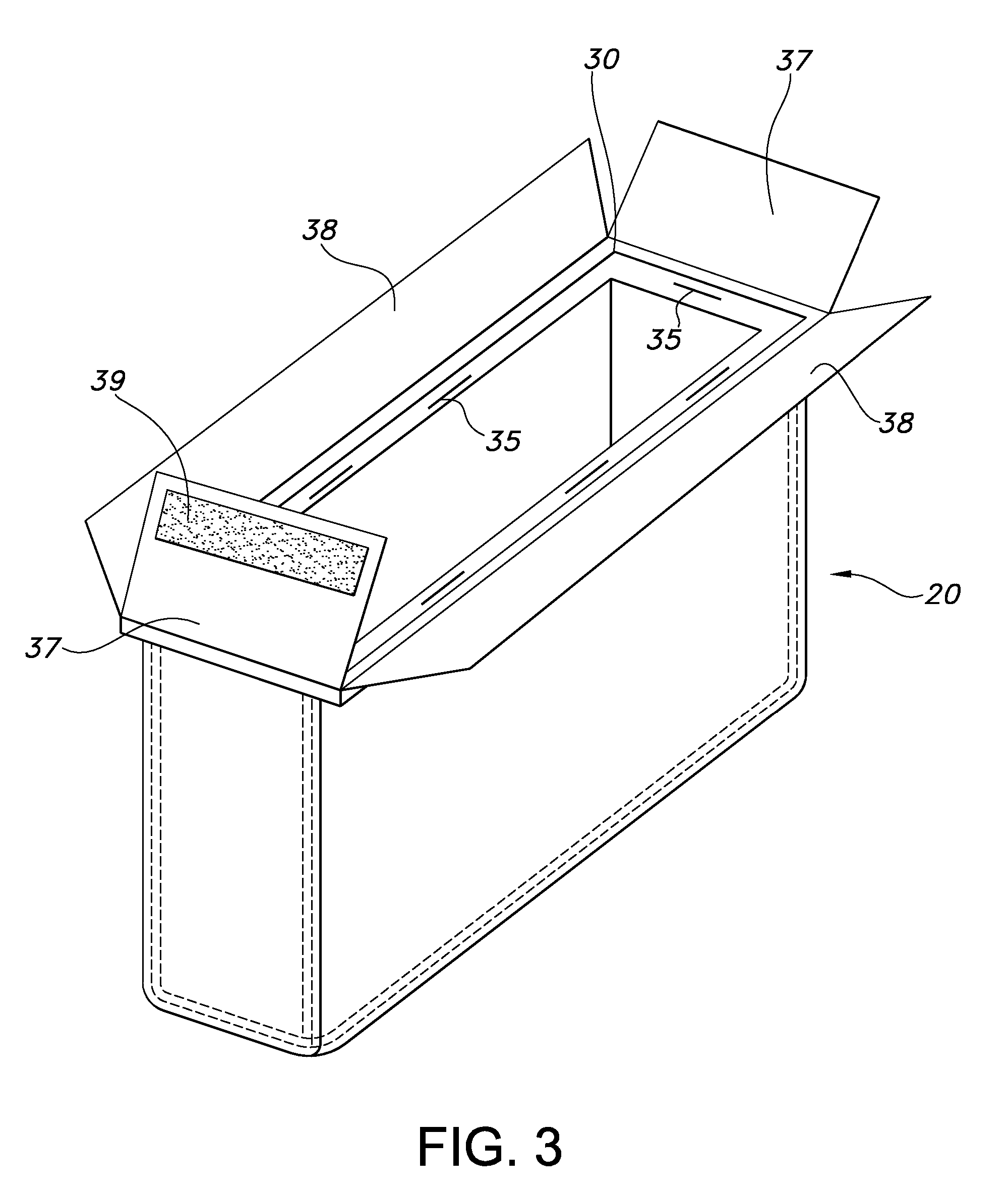

[0035] Reference will now be made in detail to one or more embodiments of the invention, examples of which are illustrated in the drawings. Each example and embodiment is provided by way of explanation of the invention, and is not meant as a limitation of the invention. For example, features illustrated or described as part of one embodiment may be used with another embodiment to yield still a further embodiment. It is intended that the invention include these and other modifications and variations as coming within the scope and spirit of the invention.

[0036] The system of disposal of the present invention may be used for any refuse disposal needs. For simplicity the invention is discussed and illustrated in terms of the specific needs and application for use in sanitary product disposal and other specific waste disposal applications. However, such examples are not intended to be limiting. Such concepts are applicable to not only to the specific waste disposal applications discusse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com