Axial compression enhanced tubular expansion

a tubular expansion and axial compression technology, applied in the field of expanding tubulars, can solve the problems of increasing the overall length of the tubular, expanding the tubular, and currently limited to an expansion of 10%-25% of the original diameter of the expandable tubular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

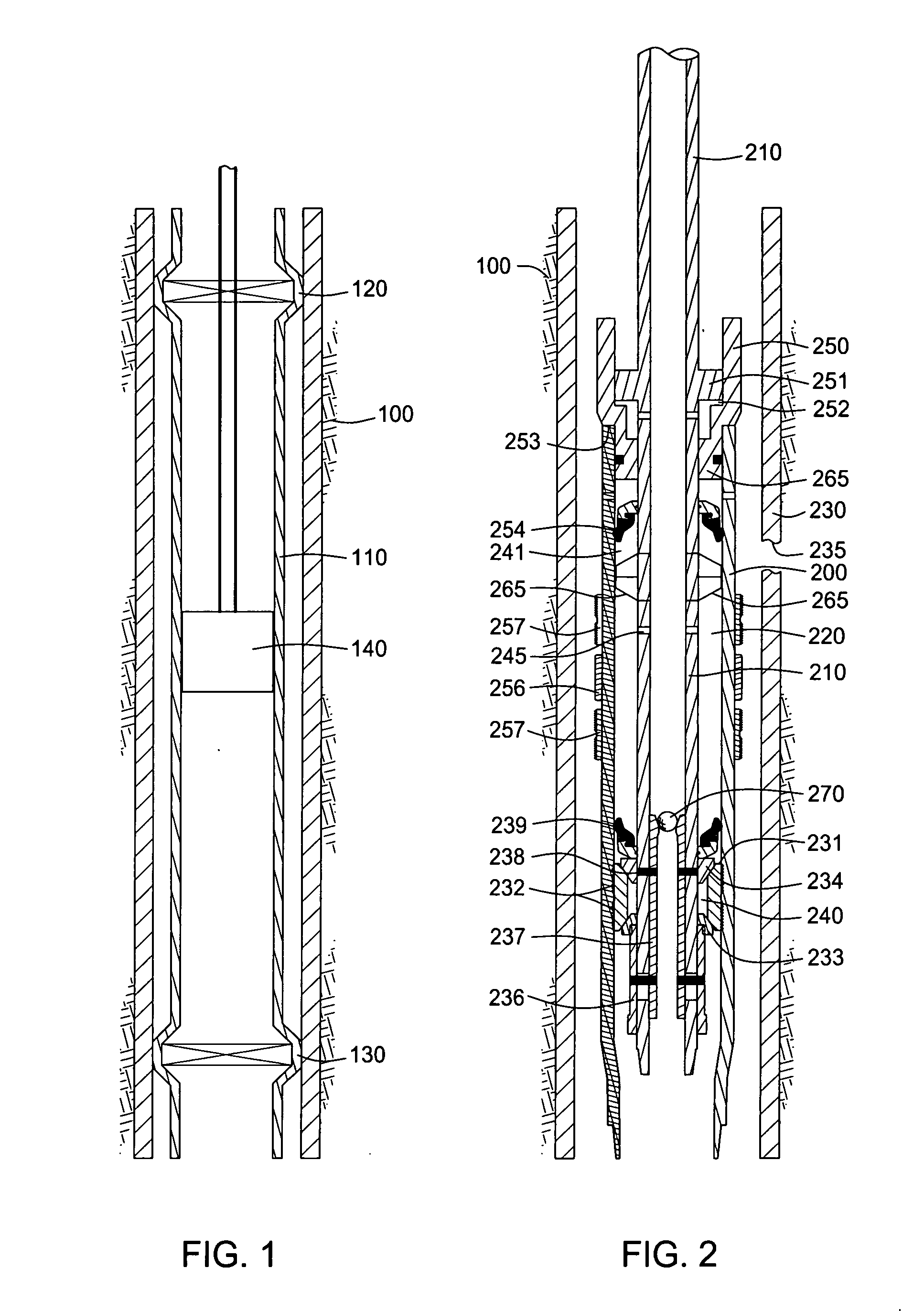

[0019]FIG. 1 illustrates a cross-sectional view of a wellbore 100 and a tubular 110 disposed therein. The tubular 110 can be casing or any other type of tubular used in downhole drilling operations, such as a liner or a patch. First and second fixed locations 120, 130 spaced apart along the length of the tubular 110 substantially prevent axial movement of the tubular 110 in the wellbore 100 such that the distance between the fixed locations 120, 130 cannot vary. The fixed locations 120, 130 can be achieved by any method or combination of methods known in the art, such as by using anchors or slips on an outside of the tubular 110 to engage a surrounding surface, by selectively expanding the tubular 110 at one or both of the fixed locations 120, 130 into frictional contact with the surrounding surface or by locating the bottom of the tubular 110 on a stop such as a plug, a packer or a bottom of the borehole (see, FIGS. 9-12). In the embodiment shown in FIG. 1, the fixed locations 120,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com