Bocce ball

a bocce ball and ball technology, applied in the field of bocce ball, can solve the problem that the cost cannot be efficiently lowered as expected, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

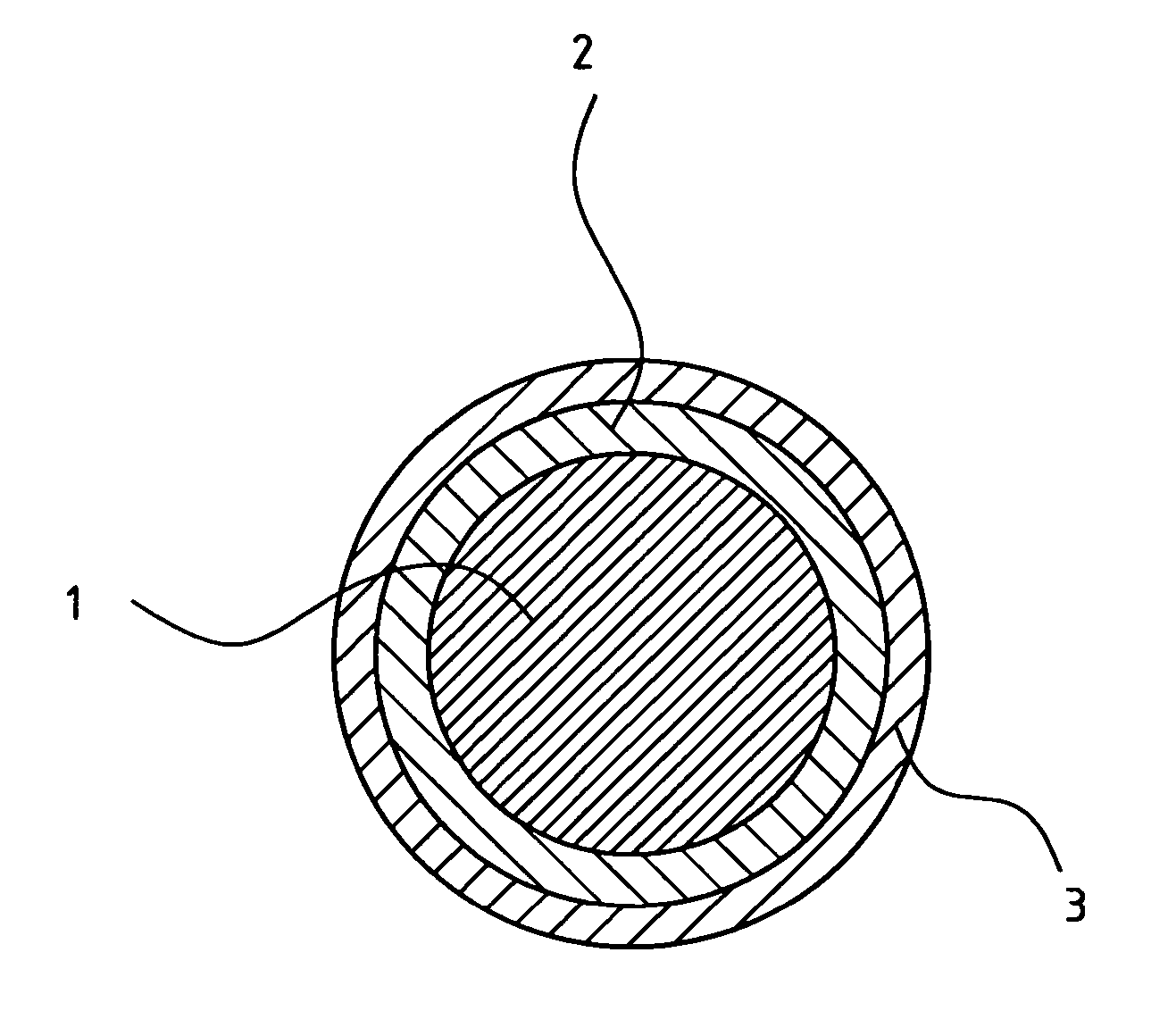

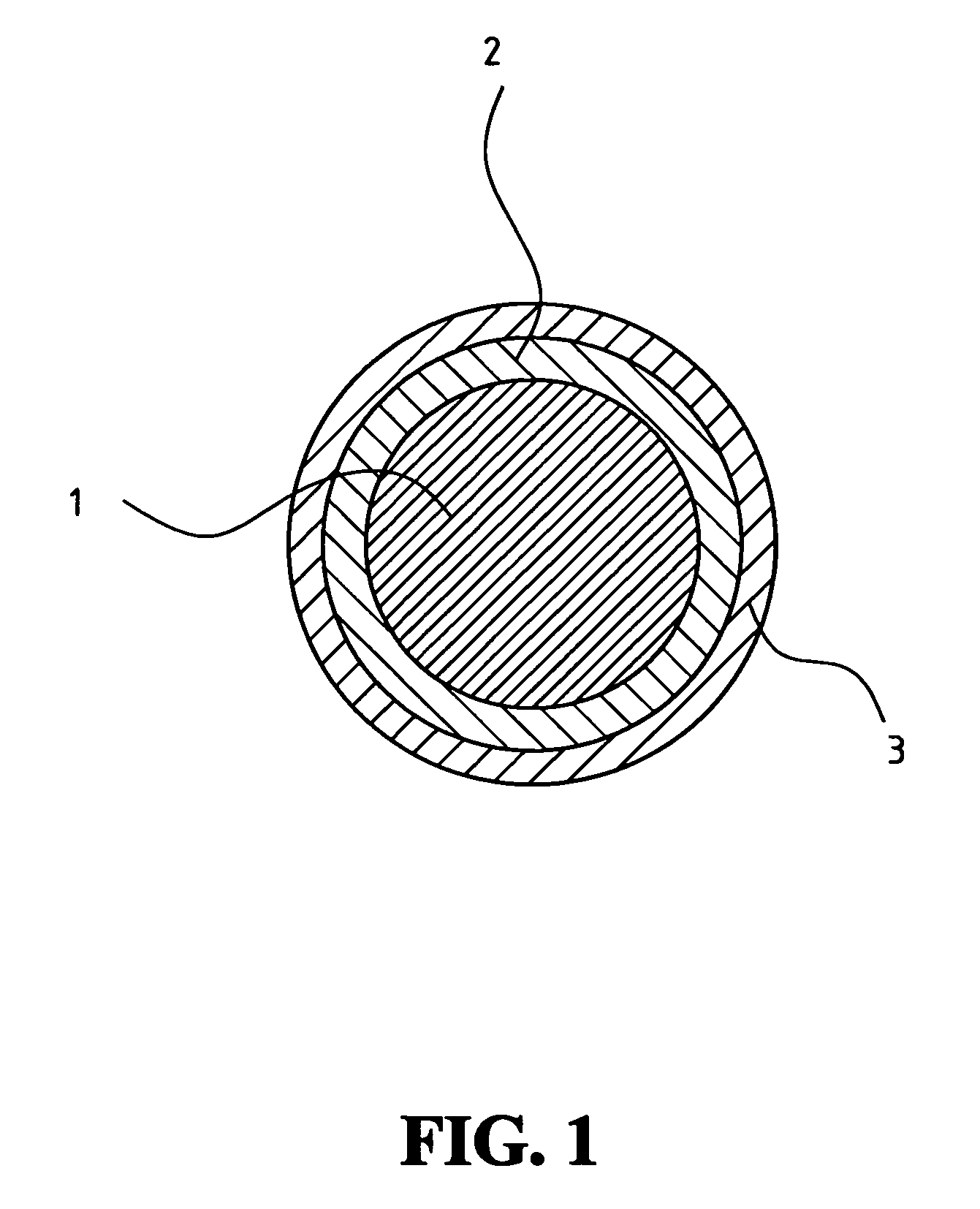

[0012] With reference to the drawings and in particular to FIG. 1, a Bocce ball constructed in accordance wit the present invention comprises, sequentially from inside to outside, a core layer 1, a medium layer 2, and a body layer 3. The body layer 3 and the medium layer 2 are formed of different materials respectively. The medium layer 2 has a high adhesion for fixedly sticking the core layer 1 as well as the body layer 3 to keep the Bocce balls intact when they collide each other during playing, and the body layer 3 must be firm and indomitable. In an embodiment, the body layer 3 is made of unsaturated polyester resin while the medium layer 2 is made of acrylic and enclosing the core layer 1. The core layer 1 is made to provide the standard weight of the ball, and can be made of any desired material. For example, the core layer 1 can be made of iron sand, racks, rubber, waste rubber, and nylon, which are selected for lowering the overall costs.

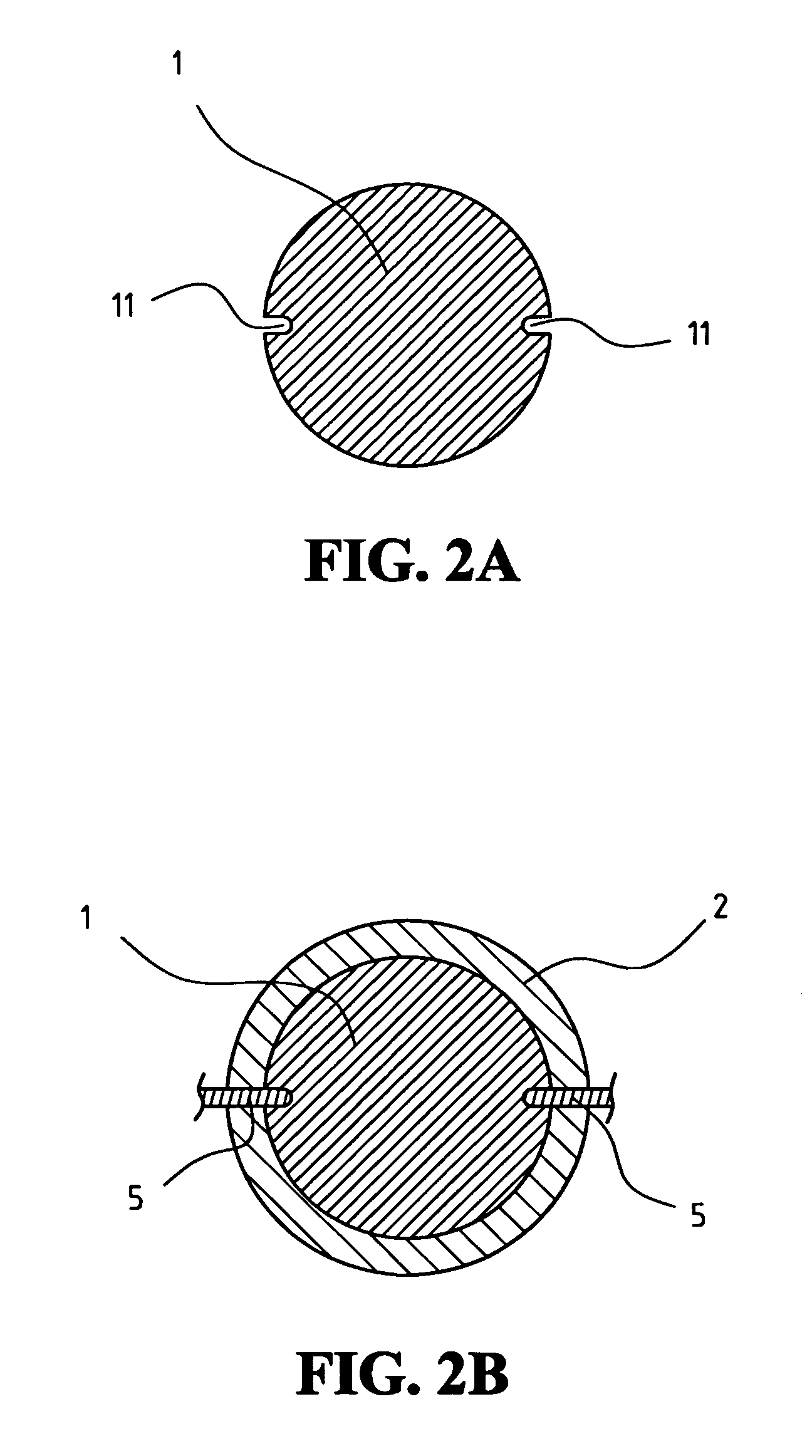

[0013]FIGS. 2A-2D show a fabrication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com