Metal burner membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

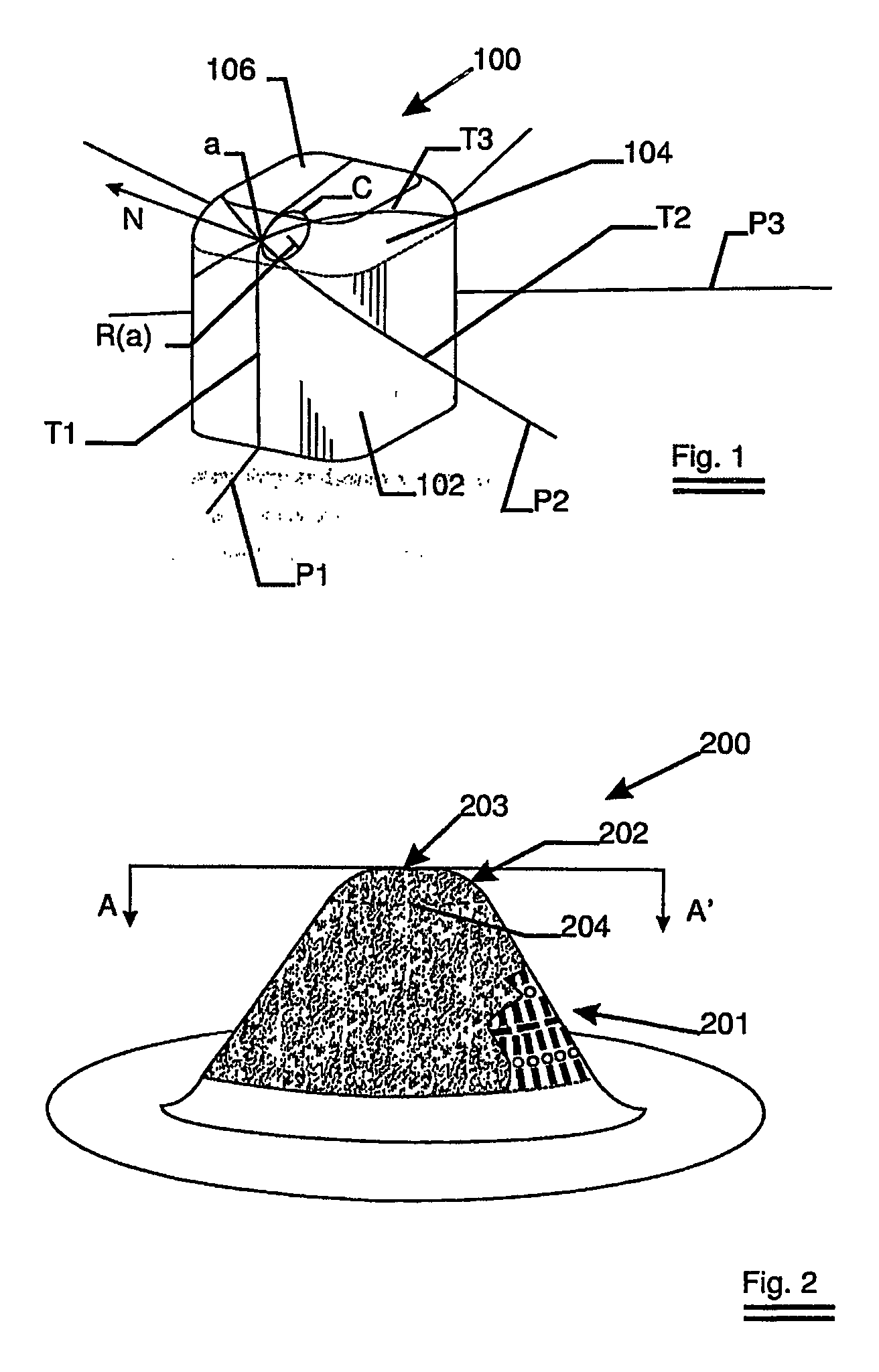

[0045] The basic geometrical features of the invention are illustrated in FIG. 1 where a shape 100 of a burner membrane is depicted consisting out of a base section 102, a transition section 104 and a top section 106. Take ‘a’ as point under consideration ‘a’ has its normal N to the surface. The planes P1, P2 and P3, all containing the normal N, cut the surface of the burner along different trajectories T1, T2 and T3 respectively. The osculating circle C touches T1 in ‘a’. If will be clear that of all planes containing N, the plane P1 determines the trajectory T1 with the smallest radius of curvature R(a) at ‘a’. If now for every point Y (not indicated on FIG. 1) of the transition section this R(x) is determined, the smallest value of all R(x)'s can be chosen. When the procedure is applied to the base section 102 a smallest radius of curvature ‘Rbase’ is obtained. Similarly, a smallest radius of curvature ‘rtransition’ can be found for the transition region. It is essential to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com