Self-cooling container for liquids

a container and liquid technology, applied in the field of self-cooling containers for liquids, can solve the problems of reduced cooling efficiency, excessive weight, liquid volume displacement loss in containers, etc., and achieve the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

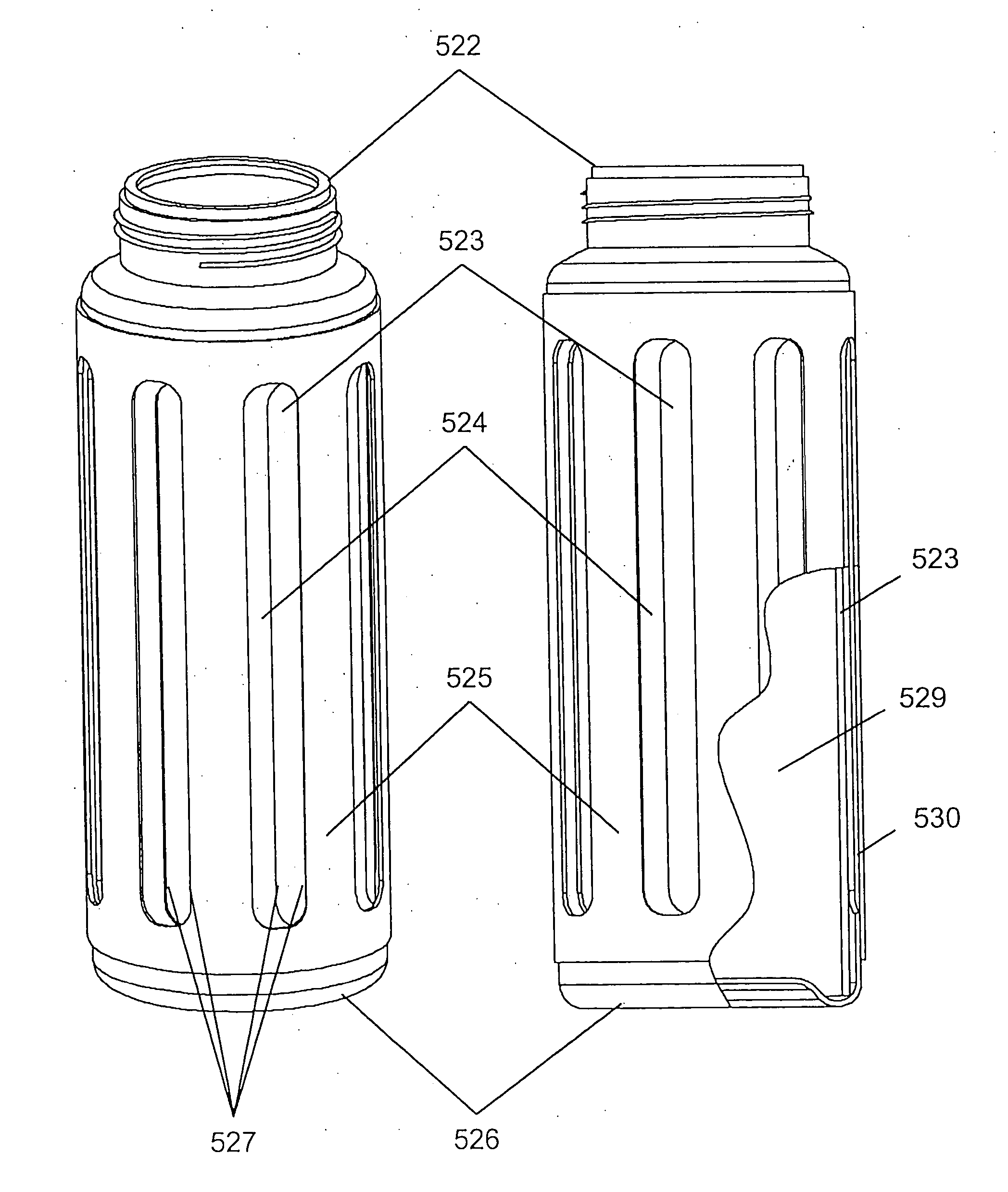

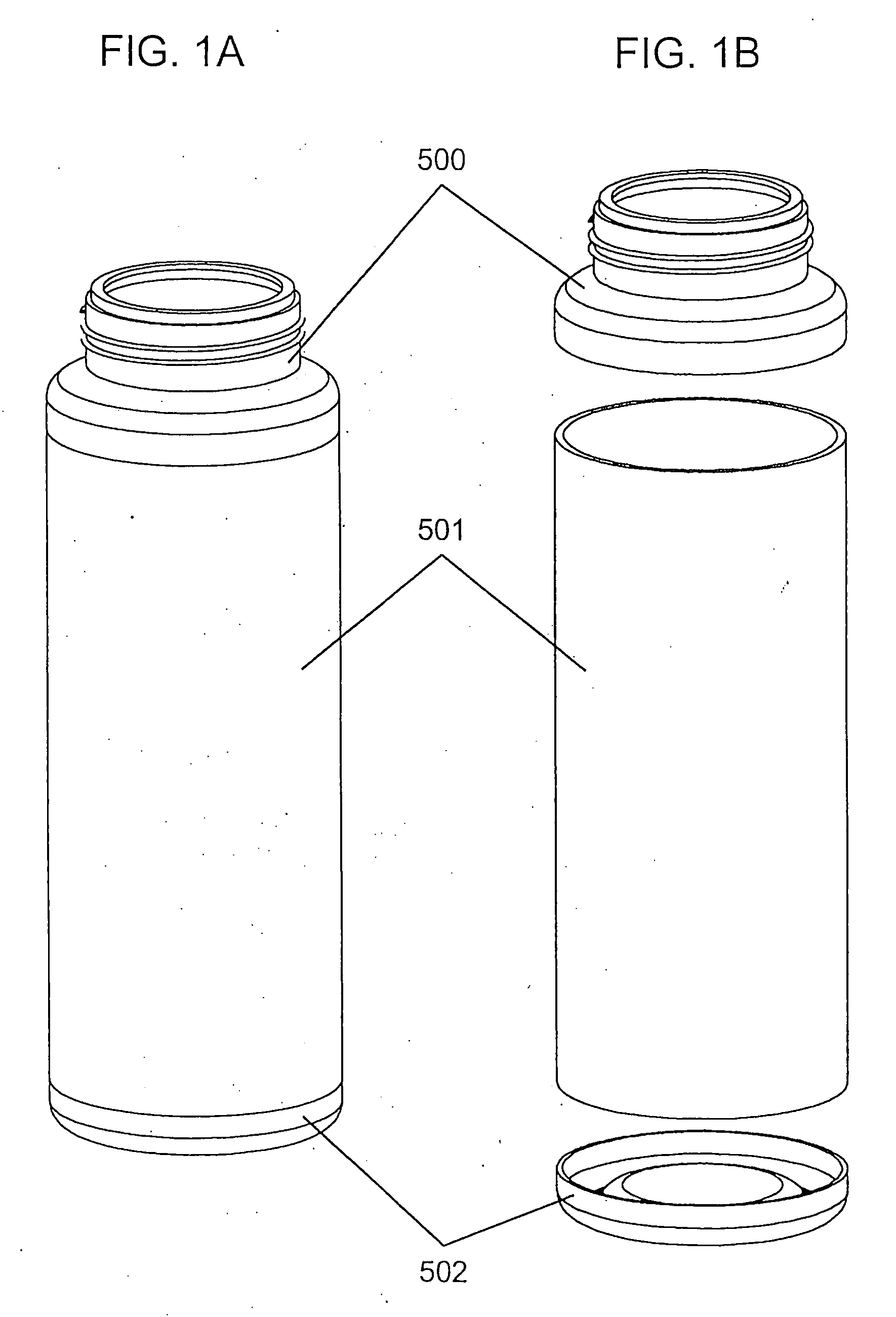

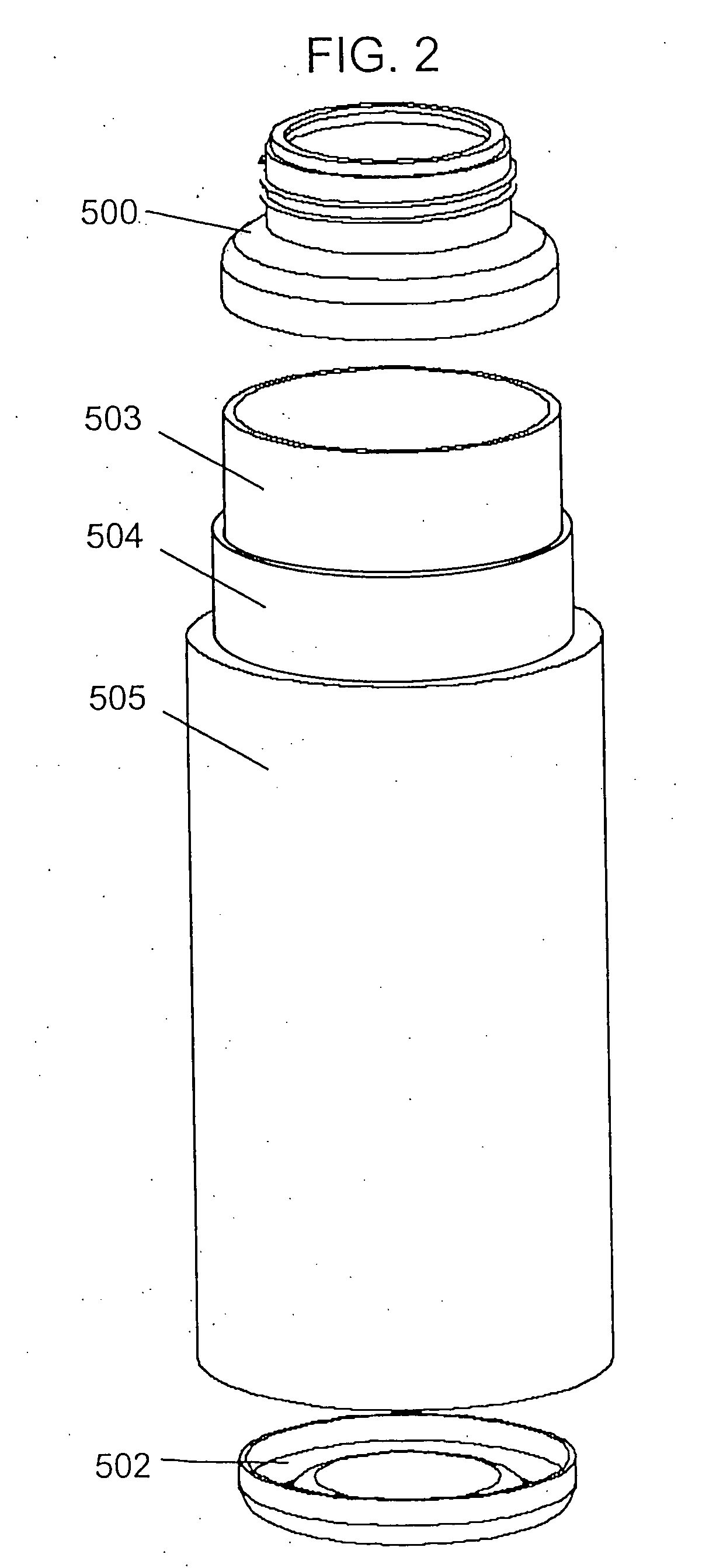

[0031] Disclosed herein are containers and enclosures that use pervaporative cooling to cool a liquid or item residing in such container or enclosure. In preferred embodiments, the containers are comprised of porous vent materials, also called porous matrices. In one embodiment, the container forms part of a pervaporatively-cooled garment. Porous matrices may be made of any of a wide variety of materials, including, but not limited to, plastics, elastomers, metals, glass, and ceramics. Combinations of plastics, elastomers, metals, glasses, or ceramics may also be used. The combinations may be intimate, such as from blending of two or more components to become co-sintered, or may be layered, such as from laminate structures derived from two or more materials. Combinations of different plastics, elastomers, metals, glasses, or ceramics can also be co-sintered or fabricated into laminate structures for use in pervaporative containers. Preferred plastics for porous vent materials includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com