Pedestal structure for raised access floors

a technology for access floors and pedestals, which is applied in the direction of building roofs, constructions, building components, etc., can solve the problems of difficult recovery, damage to the surface of floors, and the intertwining of lines becomes more and more complicated, so as to increase the leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

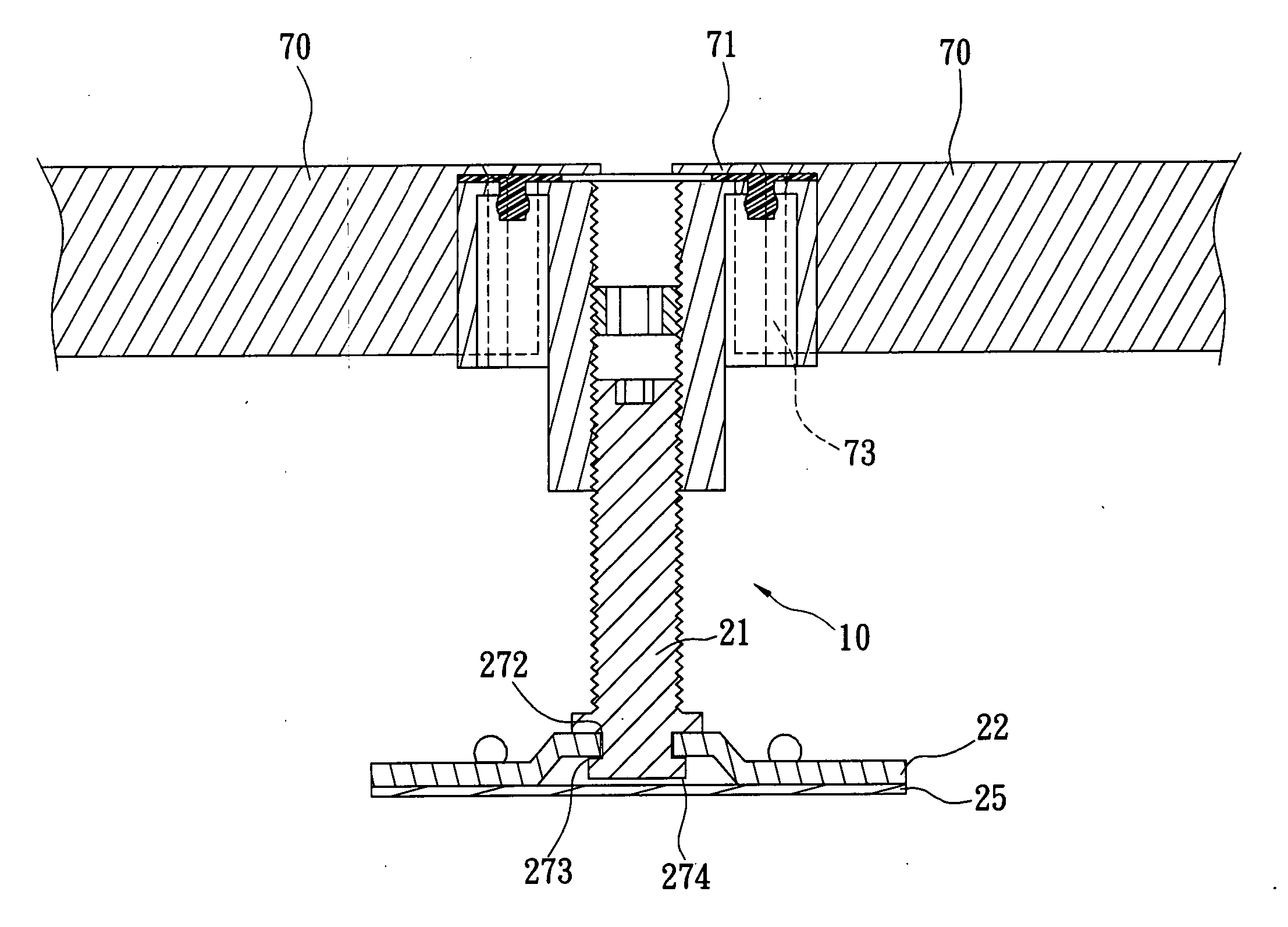

[0029] Referring firstly to FIGS. 2-3B showing perspective views and schematic sectional views of a preferred embodiment of a pedestal 10 of the present invention, the pedestal 10 comprises: a supporting seat 20, a fixing seat 30 and a socket set screw 40.

[0030] Wherein the supporting seat 20 has on the top thereof a screw bolt 21 which is connected on its bottom with a bottom seat 22; the supporting seat 20 basically is metallic and has sufficient strength. The screw bolt 21 has on the top thereof a hexagonal adjusting hole 23; the bottom of the screw bolt 21 is in a shape of “H”. The bottom seat 22 has a protruding portion 27 with a pivot hole 271 to have the bottom of the screw bolt 21 can be pivotally connected with the pivot hole 271. The pivot hole 271 has a slightly larger diameter, in order that small gaps 272, 273 are formed between the “H” shaped bottom of the screw bolt 21 and the pivot hole 27. The bottom seat 22 has thereon a plurality of openings 24, further has on it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com