Connection block with bar-adapting trenches for adapting and holding framing bars at fixed orientations

a technology of connecting blocks and trenches, which is applied in the direction of buildings, buildings, constructions, etc., can solve the problems of difficult assembling and disassembling, lack of secure and reliable structural integrity, and bulky apparatuses, and achieve the effect of convenient and flexible transportation and lowering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

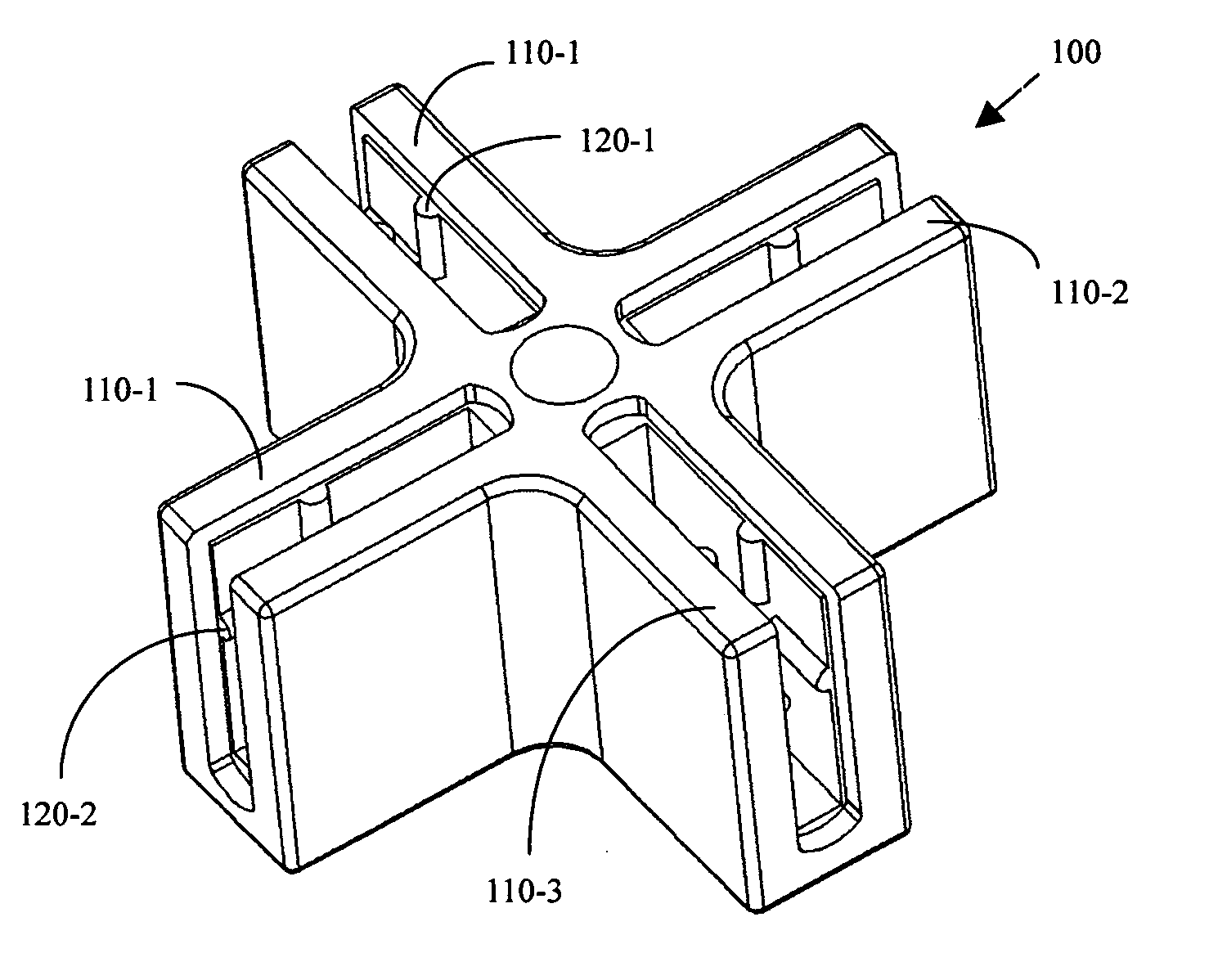

[0023]FIG. 2 is a top perspective view of a corner connector 100 of this invention. As shown in FIG. 1, the corner connector 100 includes four interconnected adapting and holding trenches 110-1, to 110-4 configured with fixed orientation relative to each other, e.g., perpendicular to each other on a same horizontal plane. The wall surface of the trenches 110-1 to 110-4 further includes ridges of different shapes, e.g., hemisphere ridge 120-1 and platform ridge 120-2.

[0024] Referring to FIG. 3 for corner connector 100 to adapt and hold multiple framing bars 130-1 to 130-6 inserted into the trenches 110-1 to 110-4 and held securely therein. These framing bars 130-1 to 130-6 when inserted into the trenches 110-1 to 110-4 are prevented form angular movement by the platform ridge 120-2 and from accidentally slipping out as the hemisphere ridges 120-1 are pressed onto these framing bars.

[0025] Referring to FIG. 4 for another corner connector 150 for adapting and securely holding four fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com